14

English

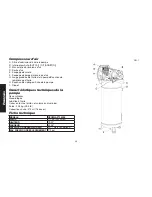

SPRAY

GUN

AIR

TOOL

DRAIN

LEGS

FILTER /

MOISTURE

TRAP

DIRT

LEGS

DRAIN

VALVES

DRAIN

VALVE

LUBRICATOR

REGULATOR

GLOBE VALVE /

AIR DISCHARGE

VALVE

MAIN DISTRIBUTION AIR LINES

Slope pipe in direction of air flow.

Water condensate flows along

bottom of pipe to drain legs,

preventing it from entering feeder

lines.

REGULATOR

BALL

FILTER

FLEXIBLE

COUPLING

DRAIN

VALVE

TYPICAL

COMPRESSED AIR

DISTRIBUTION

SYSTEM

AIR FLOW

AIR FLOW

FEEDER LINES SLOPE

WITH AIR FLOW

AIR USAGE

LINES

AIR

COMPRESSOR

FILTER /

MOISTURE

TRAP

FOR BEST PERFORMANCE

the distance between the

compressor and the

moisture trap should be as

long as possible

RISK OF BURSTING. ALWAYS USE

METAL PIPING AND FITTINGS.

DRAIN

VALVES

5 MICRON

FILTER

.01 MICRON

FILTER

How to Use Your Unit (Fig 3)

How to Stop:

Set the Auto/Off switch to “Off”.

Before Starting

WARNING:

Do not operate this unit until you read this instruction

manual for safety, operation and maintenance instructions.

Break-in Procedure

NOTICE:

Risk of property damage. Serious damage may result if

the following break-in instructions are not closely followed.

This procedure is required

before

the air compressor is put into

service and when the check valve or a complete compressor pump

has been replaced.

1. Make sure the Auto/Off switch is in the “Off” position.

2. Check oil level in pump. See

Oil

paragraph in the

Maintenance

section for instructions.

3. Recheck all wiring. Make sure wires are secure at all terminals

connections. Make sure all contacts move freely and are not

obstructed.

4. Open the drain valve (counterclockwise) fully to permit air to

escape and prevent air pressure build up in the air tank during

the break-in period.

5. Move the Auto/Off switch to “Auto” position. The compressor

will start.

6. Run the compressor for 30 minutes. Make sure the drain valve

and all air lines are open so there is only a minimal air pressure

build-up in tank.

NOTE:

After about 30 minutes, If the unit does not operate

properly, SHUT DOWN IMMEDIATELY, and contact

Product Service.

7. Check all air line fittings and connections/piping for air leaks

by applying a soap solution. Correct if necessary.

NOTE:

Minor

leaks can cause the air compressor to overwork, resulting in

premature breakdown or inadequate performance.

8. Check for excessive vibration. Readjust or shim air compressor

Summary of Contents for DXCMLA3706056

Page 87: ...87 Español NOTES ...