English

4

Intended Use

Your 2-N-1™ Flooring Nailer is designed for professional

installation of hardwood flooring.

CAUTION:

Your flooring nailer can be used to install

pre-finished flooring however caution must be used

to ensure that the finish is not damaged by the tool. It

is recommended that the tool be tested on a sample

section to be certain that the tool and technique of

use do not leave marks on the finish. This procedure

should be followed before each job due to variations

in flooring and tool condition.

Your nailer is a professional power tool.

DO nOT

let children come into contact with the tool.

Supervision is required when inexperienced operators use

this tool.

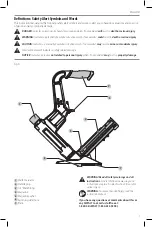

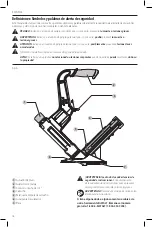

Components (Fig. A)

WARNING:

Never modify the power tool or any part

of it. Damage or personal injury could result.

Refer to Figure A at the beginning of this manual for a

complete list of components.

Additional Safety Warnings

• Use the

D

e

WALT

pneumatic tool only for the purpose for

which it was designed.

• Never use this tool in a manner that could cause a fastener

to be directed toward the user or others in the work area.

• Do not use the tool as a hammer.

• Always carry the tool by the handle. Never carry the tool

by the air hose.

• Do not alter or modify this tool from the original design or

function without approval from

D

e

WALT

.

• Always be aware that misuse and improper handling of

this tool can cause injury to yourself and others.

• Before using the tool, verify that the actuator is in the non-

actuated position. With the tool disconnected from the air

supply, depress the actuator and confirm it returns to the

non-actuated position.

• Never leave a tool unattended with the air hose attached.

• Do not operate this tool if it does not contain a legible

WARNING LABEL.

• Do not continue to use a tool that leaks air or does

not function properly. Notify your nearest

D

e

WALT

representative if your tool continues to experience

functional problems.

TO PREVENT ACCIDENTAL INJURIES:

• Never place a hand or any other part of the body in nail

discharge area of tool while the air supply is connected.

• Never point the tool at anyone else.

• Never engage in horseplay.

• Never actuate the tool unless nose is directed at the work.

• Always handle the tool with care.

• Do not actuate the tool while loading.

Adjustments and Usage Prep

Air supply and Connections

WARNING:

Do not use oxygen, combustible

gases, or bottled gases as a power source for this

tool as tool may explode, possibly causing injury.

Fittings

Install a male plug on the tool which is free flowing

and which will release air pressure from the tool when

disconnected from the supply source.

hoses

Air hoses should have a minimum of 150 p.s.i. (10.6 kg/cm2)

working pressure rating or 150 percent of the maximum

pressure that could be produced in the air system. The

supply hose should contain a fitting that will provide “quick

disconnecting” from the male plug

?

on the tool.

supply source

Use only clean regulated compressed air as a power source

for this tool. NEVER USE OXYGEN, COMBUSTIBLE GASES, OR

BOTTLED GASES, AS A POWER SOURCE FOR THIS TOOL AS

TOOL MAY EXPLODE.

Regulator

A pressure regulator with an operating pressure of

0 - 125 p.s.i. (0 - 8.79 KG/CM2) is required to control the

operat iing pressure for safe operation of this tool. Do not

connect this tool to air pressure which can potentially

exceed 200 p.s.i. (14 KG/CM2) as tool may fracture or burst,

possibly causing injury.

Operating Pressure

Do not exceed recommended maximum operating pressure

as tool wear will be greatly increased. The air supply must

be capable of maintaining the operating pressure at the

tool. Pressure drops in the air supply can reduce the tool’s

driving power. Refer to

Tool Specifications

for setting the

correct operating pressure for the tool.

Filter

Dirt and water in the air supply are major causes of

wear in pneumatic tools. A filter will help to get the best

performance and minimum wear from the tool. The

filter must have adequate flow capacity for the specific

installation. The filter has to be kept clean to be effective

in providing clean compressed air to the tool. Consult the

manufacturer’s instructions on proper maintenance of your

filter. A dirty and clogged filter will cause a pressure drop

which will reduce the tool’s performance.

lubrication

Frequent, but not excessive, lubrication is required for best

performance. Use Air Tool Lubricant, Mobil Velocite #10, or

equivalent. Do not use detergent oil or additives as these

lubricants will cause accelerated wear to the seals and

bumpers in the tool, resulting in poor tool performance and

frequent tool maintenance. Only a few drops of oil at a time

is necessary inserted into air fitting opening. Too much oil

will only collect inside the tool and will be noticeable in the

exhaust cycle.