10

PROBLEM

1. Chisel angle too great—

greater than 135°

2. Chisel angle too small—

less than 120°

3. Bit will not drill

4. Discoloration (burning)

near cutting lips

5. Flats or chatter marks

on ground surfaces

6. Large variation in lip height

(point off center)

7. Swinghead will not stay

locked in sharpening or

dressing position

8. Hard to pivot swinghead

back and forth

9. Bent locator

10. Unit getting unusually hot

English

Troubleshooting

REMEDY

Bit was not ground close enough to

locator or was positioned incorrectly, See

Step 6 under “Preparing to sharpen.”

Edge of locator was not flat against flute.

See step 6 under “Preparing to sharpen.”

Or bit was ground too close to locator.

Insufficient relief angle. See Step 6

under “Preparing to sharpen,” for proper

positioning of bit.

Material is being removed too fast. Slow

down feed rate.

A. Looseness in pivot rod bearing

system—see adjustments

B. Wheel needs dressing

C. Feed at slower rate

D. Slow down speed of rocking motion

A. Bent bit

B. Looseness in pivot rod bearings—

follow adjustments

C. Unequal hand pressure on

swinghead while sharpening

Latch set screw needs adjustment.

Gib screws adjusted too tight.

Place a 1/8" (3 mm) bit in chuck and

bend locator until the tip is directly over

bit center or replace locator.

Check motor air intake and exhaust

openings on bottom of tool for blockage.

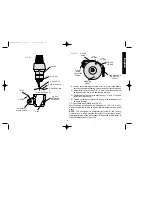

4. The Locator (Fig. 28)

The locator on the chuck of your drill bit sharpener has been

inspected at the factory for proper positioning and assembly. Should

the locator edge become damaged for any reason while grinding

during the initial learning operation of the tool, it is easily replaced

with the extra locator provided.

CAUTION: Tighten screws just enough to seat locator against

chuck. DO NOT OVERTIGHTEN

FIG. 28

CHUCK

LOCATOR

SCREWS

DW751/385103 5/2/02 12:51 PM Page 10