15

MAINTENANCE

Belt - Replacement

SERIOUS INJURY OR DAMAGE MAY OC-

CUR IF PARTS OF THE BODY OR LOOSE

ITEMS GET CAUGHT IN MOVING PARTS.

NEVER OPERATE THE OUTFIT WITH THE

BELT GUARD REMOVED. THE BELT GUARD

SHOULD BE REMOVED ONLY AFTER THE

SPARK PLUG WIRE HAS BEEN DISCON-

NECTED.

To replace belt:

1.

Disconnect spark plug wire.

2.

Remove belt guard.

3.

Loosen four engine mounting screws, two saddle/

stiffener plate screws, handle set screw, and

stiffener bar nut on engine and slide engine toward

compressor.

4.

Remove belt and replace with new.

5.

Push the engine back into regular position. Achieve

belt tension by inserting a large screwdriver into the

hole in the saddle which is located on the belt guard

side of the saddle below the engine and prying the

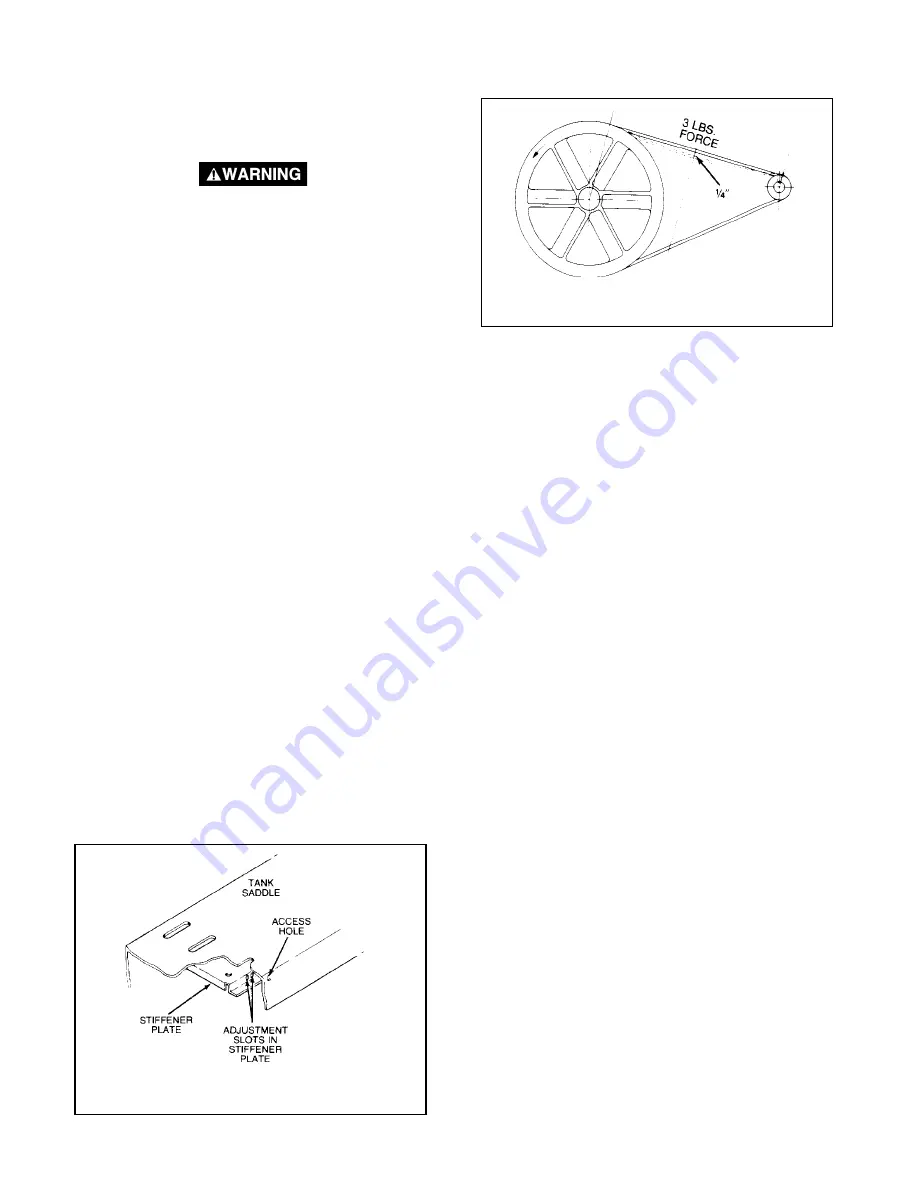

stiffener plate back. See Figure 8. Proper tension is

approximately 1/4" belt deflection measured mid-

way between the pulley and flywheel when a 3-

pound weight or equivalent finger pressure is ap-

plied at this point. See Figure 9.

NOTE

The belt must be centered over the grooves on

the flywheel and engine pulley.

Figure 8

Before You Store The Air Compressor:

1.

Review the "Operating Procedures" and "Mainte-

nance" sections on the preceding pages and per-

form maintenance as necessary. Drain the water

from the air tank.

2.

Review the Briggs & Stratton "Operating and Main-

tenance Instructions".

3.

Remove the air tool or accessory.

4.

Protect the air hose from damage (such as being

stepped on or run over). Wind it loosely around the

outfit handle.

5.

Store the compressor in a clean and dry location.

Figure 9

6.

Hold belt tension until two engine mounting screws

are tightened securely.

7.

Tighten remaining engine mounting screws, saddle/

stiffener plate screws, handle set screw and stiff-

ener bar nut.

8.

Reinstall belt guard and screws.

NOTE

Once the engine pulley has been moved from

its factory set location, the grooves of the

flywheel and pulley must be aligned within 1/

16" to prevent excessive belt wear.

The compressor flywheel and motor pulley must be

inline (in the same plane) within 1/16" to assure belt

retention within sheave grooves. To check alignment,

disconnect spark plug wire and remove the beltguard.

Place a straight edge against the outside of the fly-

wheel and measure the distance from it to the nearest

groove. Alignment is achieved when the other end of

the straightedge is within 1/16" of the measured di-

mension at the pulley grooves. Squareness is achieved

when the pulley grooves are an equal distance from the

straightedge on both sides of the motor shaft.

Pulley and Flywheel - Alignment

Storage

Summary of Contents for MG4-OLENG-2B

Page 18: ...18 SERVICE NOTES...

Page 19: ...19 SERVICE NOTES...