PAGE 2 SB-6-132-G

receptacle. Prevent vinyl tubing from

becoming kinked which would prevent

free movement of liquids discharged

from the automatic or manual drain.

8. An optional manual drain HAF-11) can

be installed in place of the automatic

drains.

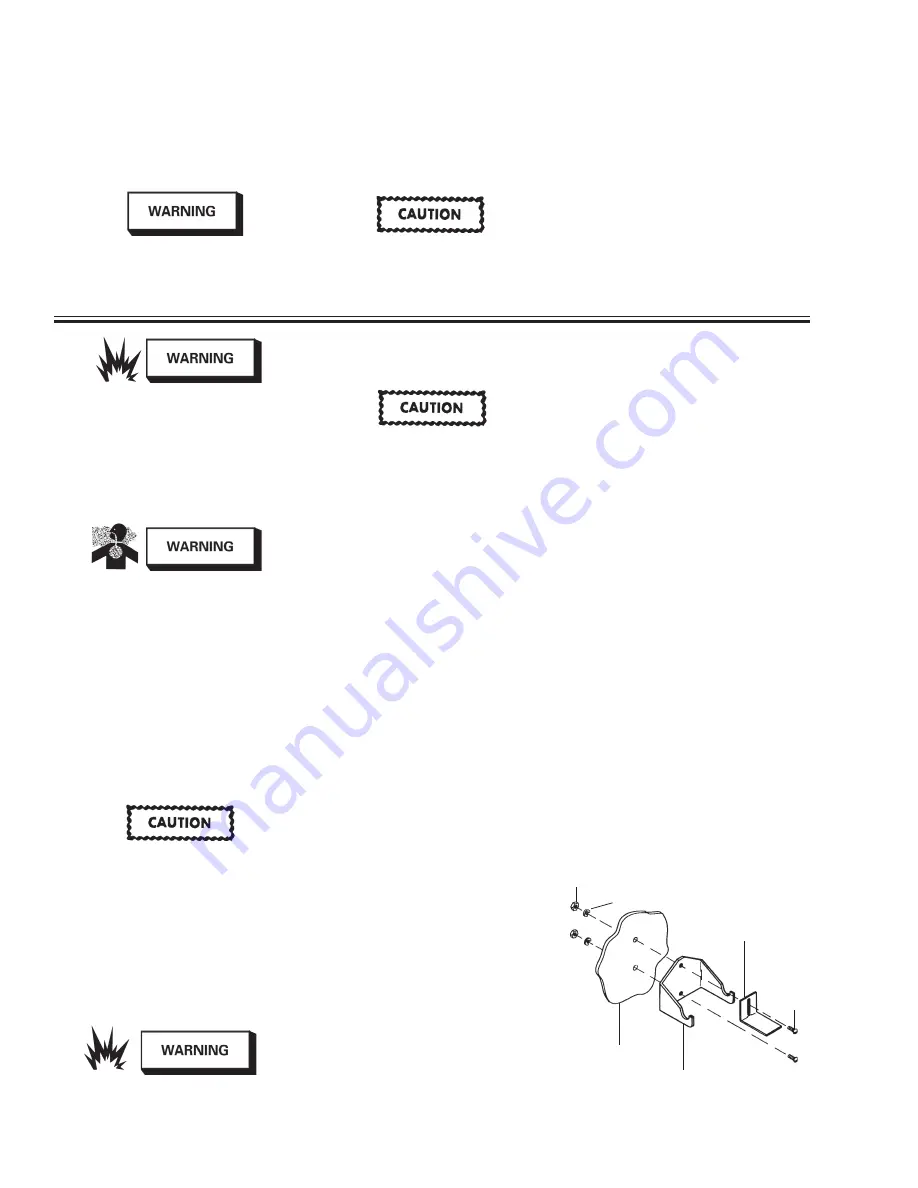

INSTALLATION – MOUNTING BRACKETS

1. Use the mounting bracket as a template

for locating the mounting holes.

2. Drill appropriate sized holes through

booth wall as shown in Figure 2. Two

5/16" round head screws, nuts and lock-

washers are supplied. If mounting into

a solid or hollow wall, use anchors (not

included).

3. Assemble mounting bracket to wall,

positioning “L” bracket with top screw.

4. Tighten bottom screw firmly. Leave top

screw partially loose so “L” bracket can

slide up out of the way.

5. Place filter in the bracket, positioning

between curved saddle ears. See Figure

1 on Page 1.

6. Slide “L” bracket down against top of

filter, then firmly tighten the top screw.

SAFETY PRECAUTIONS

This manual contains important information that all users must know and understand before using the equipment. This information

relates to USER SAFETY and PREVENTING EqUIPMENT PROBLEMS.

To help you recognize this information, we use the following terms to draw your attention to certain equipment labels and portions of

this manual. Please pay special attention to any label or information that is highlighted by one of these terms:

Note

Information that you should pay

special attention to.

Important information that tells

how to prevent damage to equip-

ment, or how to avoid a situation

that might cause minor injury.

Important information to alert

you to a situation that might cause

serious injury if instructions are not

followed.

INSTALLATION – AIR STATION

Risk of explosion and injury. Release

all air pressure from system before

servicing system. Be sure to read

and understand all Service Bulletins

on the separate components before

using the system. Use only specified

DeVilbiss parts.

Risk of equipment damage! Do not

install your air station where it is

subjected to sudden depressuriza-

tion cycles exceeding 20 PSIG. Quick

relieving air solenoid valves, typical

in some spray booths, will eventually

fail pressure gauges and filters.

To minimize sudden depressurization effect,

replace the existing solenoid with a "slow

closing solenoid valve". (One source: Auto-

matic Switch Co). Or, install an air adjusting

valve at the existing solenoid valve outlet.

For ease of installation and maintenance,

attach the assembled air station to the main

air line using a pipe union, (not included).

1. Be sure to read all Warnings and Cautions

in this manual and component manuals

on the unit before installation or using

this equipment.

2. Install air station system as close as pos-

sible to the point where the air is being

used. Use enclosed mounting bracket

to support Air Station.

3. Install main shut-off valve (supplied by

user) upstream of air drying system to

allow maintenance to the unit.

4. Install unit with air flow through filter in

direction of arrow on top of filters.

5. Minimum 3/4" NPT piping is recom-

mended. Avoid using fittings, couplings,

etc. that restrict air flow.

6. Maximum inlet pressure and operating

temperature is: 150 PSIG and 120° F

(48.9 C)

7. Three 6' lengths of vinyl tubing are

shipped loose with the system. Slide

over drains which protrude from bot-

tom of the filters. Place the other

end of vinyl tubing into appropriate

Figure 2 – Mounting Bracket

5/16" Nuts

5/16"

Rd. Hd.

Machine

Screws

“L” Bracket

5/16" Lockwashers

Booth Wall

Mounting Bracket

Risk of illness or death. Carbon mon-

oxide can cause nausea, fainting or

death. Stop using if carbon monoxide

is present. This unit does not remove

carbon monoxide. A carbon monox-

ide monitor should be incorporated

into your air supply line to warn of the

presence of carbon monoxide.

Risk of injury. Do not place unit in

service without metal bowl guard

installed. Filter units are sold only

with metal bowl guards. To minimize

the danger of flying fragments in the

event of plastic bowl failure, guard

must not be removed. If the unit is

in service without the metal bowl

guard installed, manufacturer’s war-

ranties are void and the manufacturer

assumes no responsibility for any

resulting loss. If unit has been in

service and does not have a metal

bowl guard, order one and install

before placing back in service.

Certain compressor oils, cleaning

agents and solvents may attack the

plastic and rubber components used

in the construction of this product.

This product should not be used in

conjunction with or in the vicinity

of these materials. Read and follow

material labels carefully. Please

consult DeVilbiss if in doubt.