E-4

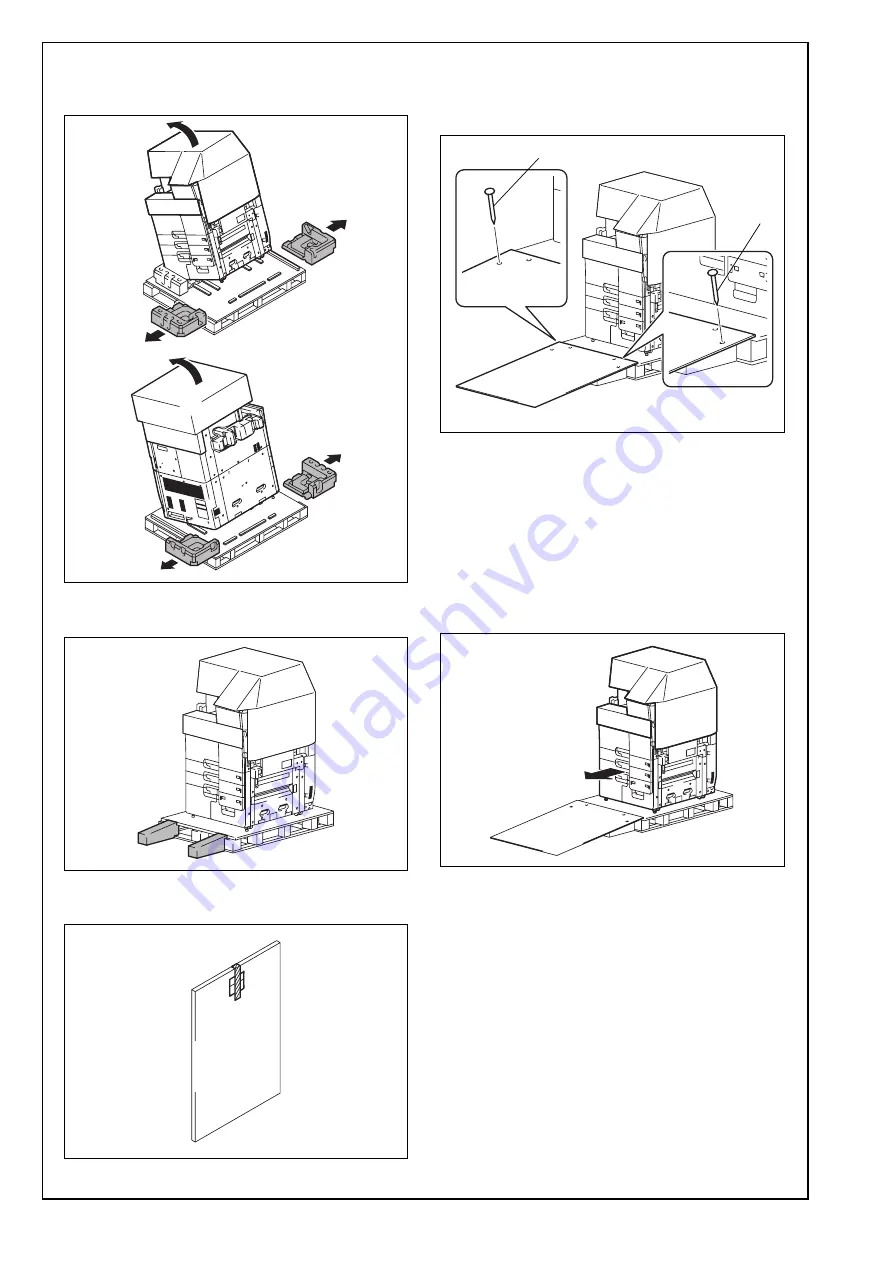

(3) Hold onto the handle of the machine and tilt the

machine to the right and left. Under this condi-

tion, remove the fixing materials.

(4) Separate the cushion into two and install them to

the pallet (at two places).

(5) Take out the slope and protective tape and

remove nails from the plastic bag.

(6) Position the slope as illustrated and drive nails in

to fix the slope in position.

Caution:

Insert the nails in the outer holes.

(7) Holding onto the front cover and the back panel

of the machine, slide the machine down along

the slope.

Caution:

Machine mass: 200 kg (440-15/16 lb)

• Perform this step on a level, stable site and

assign an adequate number of persons.

• When sliding the machine down, do not hold

onto the scanner portion.

• Do not insert your leg under the slope.

Nail

Nail