6159947020_06

Series: B

9 / 36

English

08/2017

LUBRICATION

This tool is fitted with blades which can

operate without lubricated air. However,

a small amount of oil allows the tool to

provide full power and lengthens its life.

The use of dry air with no trace of oil may

reduce the life of blades.

MAINTENANCE INSTRUCTIONS

The use of spare parts other than those

originally supplied by the manufacturer

may result in a drop in performance or

in increased maintenance and level of

vibration and in the full cancellation of the

manufacturer’s liability.

To obtain maximum efficiency from the

pneumatic tool, preserve its features

and avoid repeated repairs, a routine

inspection and repair programme

are recommended at least every 500

operating hours or every 6 months as a

minimum. In heavy-duty conditions, the

inspection program can be performed

every 3 months.

●

Disassemble the tool, clean and

check the parts carefully.

●

Check the condition of the bearings

and inspect the vanes for wear and

surface condition.

When disposing of components,

lubricants, etc... ensure that the relevant

safety procedures are carried out.

The rotor blades in this tool have a PTFE

content. The normal health and safety

recommendations concerning PTFE must

be observed when handling these rotor

blades.

●

Do not smoke.

●

Motor components must be washed

with cleaning fluid and not blown clear

with an air line.

●

The silencer must be replaced when

dirty, do not clean and re-use.

●

Wash hands before commencing any

other activity.

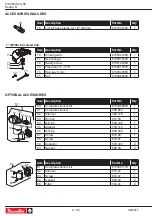

DISASSEMBLY AND REASSEMBLY

INSTRUCTIONS

Indicates direction of dismantling.

Disconnect the machine from the

compressed air supply.

Remove all accessories.

●

Before disassembling the machine,

decompress the air from the oil tank by

loosening and retightening the screw (14).

●

At each disassembly of the governor, clean

the spring housing, check the condition of the

spring and re-lubricate it carefully.

The governor has a calibrated spring

which can only be replaced by an original

spare part.

●

When re-assembling, always position the

cylinder exhaust on the opposite side of the

turbine housing.

Overspeed air shut-off device

Be particularly careful with the speed

governor and the overspeed air shut-

off device. Careless maintenance or

treatment may prevent them from

functioning correctly. If the machine

stops suddenly or does not reach rated

speed when connected to the air supply,

the overspeed shut-off device may have

closed the inlet air. The machine must

imperatively be dismantled and checked

before resetting the overspeed shut-off

device.