12

DEPA

®

Air Operated Diaphragm Pumps

n

Fasten the lifting tackle so that the

pump can be safely lifted.

n

For pumps DH40-TP/TPL please use

the corresponding lifting eye. For pumps

DH50-TP/TPL please use the available

notches.

Danger!

In order to avoid slipping of the

sling the rope must be crossed

over at the hook (Fig. 1).

Fig. 1: Transport of pump

Be careful when unpacking the pump and

proceed as follows:

■

Check the packaging material for trans-

port damage.

■

Take the pump carefully out of the pack-

aging material.

■

Check the pump for visual damage.

■

Remove the plugs from all pump ports.

■

Check seals and fluid lines for damage.

The following points must be strictly ob-

served when preparing the pump for stor-

age:

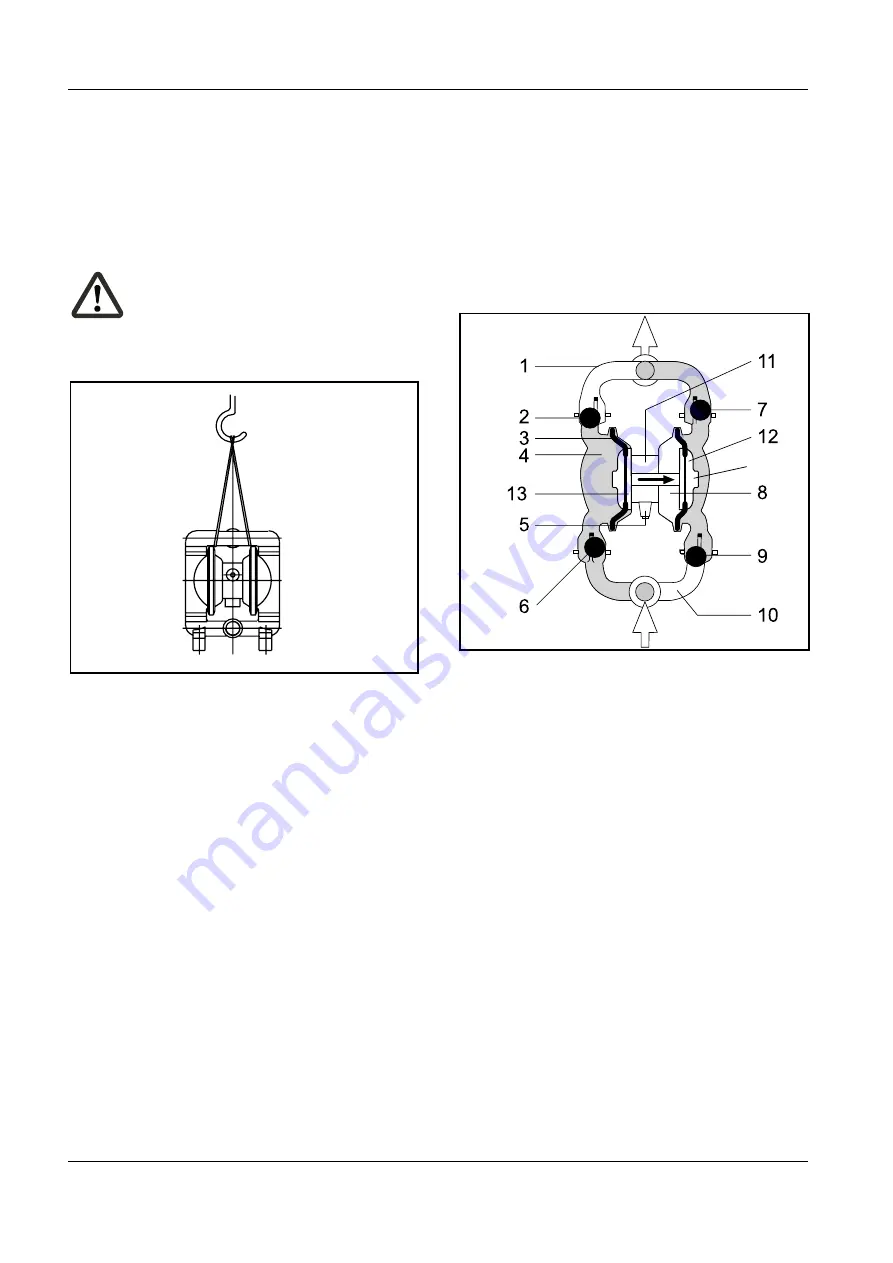

1 Discharge manifold

2 Top valve ball

(closed during suction)

3 Diaphragm

4 Pump chamber

5 Silencer

6 Bottom valve ball

(opened. Medium flows into chamber)

7 Top valve ball

(open. Product is pressed out)

8 Air chamber

(the drive air displaces the medium

via the diaphragm and at the same time

pulls back the second diaphragm)

9 Bottom valve ball

(closed during delivery)

10 Suction socket

11 Air control unit

12 Outer piston

13 Inner piston

14 Diaphragm, in the case of nopped E4

®

without outer diaphragm plate

Fig. 2: Design of pump

■

Store the pump in a dry place.

■

Thoroughly clean used pumps before

storage.

■

Do not subject stored pumps to ex-

treme temperature fluctuations.

1.3

Principle of function

14