12

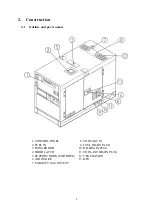

Generator

indicators

(1)

Frequency

meter

This meter indicates frequency of the output voltage.

Make sure that it indicates 50Hz during operation.

(2)

AC

ammeter

This meter indicates AC current flowing into the connected

load. Make sure that it is always pointing below the rated

current.

When running the three phase and single phase loads

together, this meter indicates total current of them.

When running either the three phases or single-phase load,

this meter indicates the current flowing into the load.

(3)

AC

voltmeter

This meter indicates AC output voltage. Make sure that it

indicates rated voltage.