SAFETY

I.

Under

the

terms

of

the

Health

&

Safety

at

Work

Act

and

for

the

operators

protection

a

Residual

Current

Device

(R.C.D)

or

Earth

Leakage

Trip

MUST

be

used

with

this

machine.

ii

Water

at

high

pressure

is

dangerous

and

can

cause

serious

injury.

This

machine

is

to

be

used

with

great

caution.

a.

NEVER

point

the

high

pressure

spray

jet

at

any

person,

animal,

glass

or

any

other

material

which

may

shatter.

b.

PREVENT

any

over

‐

spray

from

injuring

other

people

or

damaging

property.

c.

DO

NOT

even

try

to

use

a

pressure

washer

on

machinery

or

electrical

equipment

that

is

con

‐

nected

in

any

way

to

the

mains

supply.

(all

switches

in

the

off

position,

pull

out

all

plugs

and

if

possible

remove

fuses).

Cover

or

seal

electric

motors

and

fittings

to

prevent

entry

of

water.

d.

ALWAYS

when

using

machine:

‐

‐

wear

safety

goggles

and

helmet

or

helmet

with

a

visor.

‐

wear

waterproof

clothing

and

gloves.

‐

take

particular

care

with

detergents

and

chemicals.

e.

NEVER

attempt

to

disconnect

any

hose

with

pressure

in

it

or

allow

the

hose

to

be

flattened

or

kinked.

f.

DO

NOT

use

a

high

pressure

hose

from

a

ladder.

Use

a

platform

tower

or

proper

scaffolding.

g.

CHECK

that

your

supply

voltage

agrees

with

that

shown

on

the

machine.

h.

Extention

leads

are

not

recommended

for

use

with

this

equipment.

Fit

extention

hoses

or

contact

the

service

department.

i.

Where

a

cable

is

found

to

be

damaged,

the

power

must

be

switched

off

and

the

plug

re

‐

moved

before

attempting

to

remove

the

equipment.

j.

ALWAYS

disconnect

the

hoses

when

the

machine

is

not

in

operation

and

protect

the

machine

from

frost

and

cold

winds.

k.

ALWAYS

use

the

machine

in

a

well

ventilated

area.

CAUTION

‐

if

using

chemicals

some

brands

will

adversely

affect

the

brass

components

fitted

to

this

machine.

If

in

doubt

please

telephone

our

technical

department

for

advice.

Summary of Contents for Tempest 1

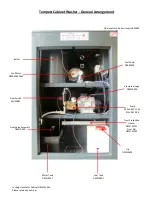

Page 9: ......

Page 10: ......

Page 17: ......

Page 19: ......

Page 20: ......

Page 21: ...HH0049 3 8 Ferrules R1A HH0053 Hose from Pump to Tap 1 2 L P Yellow Hose...

Page 27: ......

Page 31: ...Frost Stat Heater Coil all cabinets 240v Heater Coil Thermostat L N E KTW 12 3 13 1 2 3 4...

Page 32: ......

Page 33: ......

Page 34: ......

Page 36: ......

Page 39: ......

Page 40: ......

Page 41: ......

Page 46: ...Pump for Tempest 1 and Tempest 3...

Page 48: ...For Tempest 1 and Tempest 3...

Page 50: ...Pump for Tempest 4 RK 13 17 RK 15 20H RK21 15...

Page 52: ......

Page 54: ......