Step 8: Test Feedback Device

deltamotion.com

19

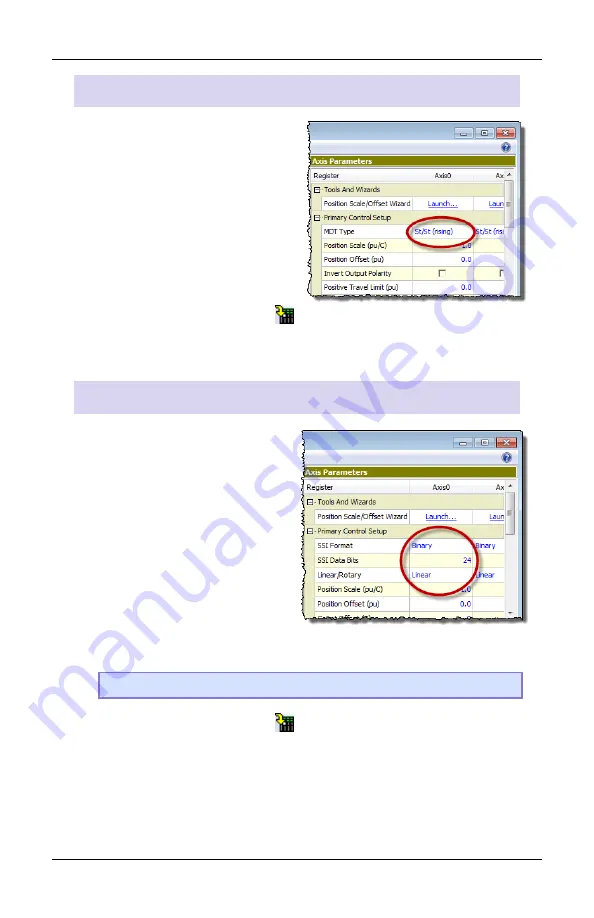

Start/Stop or PWM (Magnetostrictive) Feedback

1.

In the

Axis Parameters

, on

the

Setup

tab, set the

MDT

Type

register to the type of

magnetostrictive transducer

you have.

This information is available

from your transducer

datasheet.

2.

Click the

Download

button

to apply the changes to the RMC.

3.

Continue to the

Verify Feedback

section on page 21.

SSI Feedback

1.

In the

Axis Parameters

pane,

on the

Setup

tab, set the

following cells.

•

SSI Format

•

SSI Data bits

(e.g. 24)

•

Linear/Rotary

This information is available

from your SSI device data

sheet.

Note:

For help on a parameter, click the cell and press F1.

2.

Click the

Download

button

to apply the changes to the RMC.

3.

Continue to the

Verify Feedback

section on page 21.