Page 2

212294 Rev.

B

FOR SURFACE MOUNT HOUSING: CONTROL BOX #0

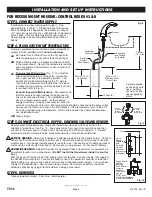

STEP 1. FAUCET INSTALLATION

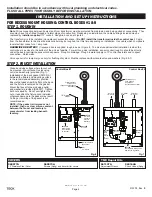

STEP 2. BATTERY BOX INSTALLATION

Mount battery box to wall under sink using the 4 supplied screws and anchors. Use

1/4” drill for wall anchors.

Be sure to install the box within the dimensions provided

so the hose and spout cable will reach connections at faucet and battery box.

Refer to illustration (Fig. 2).

STEP 3. FLUSH SYSTEM

To flush supply line, assemble these components as shown (Fig. 3) and run water for 1

minute. Shut off water supply. Attach aerator.

NOTE:

Do not connect supply to the

solenoid inlet until line is flushed directly out spout.

STEP 4. CONNECT WATER SUPPLY

Disassemble the components, reassemble the ones shown here (Fig. 4) supply line

and adaptor to the bottom fitting on box, braided hose to the top fitting on box. Turn

on water supply.

DO NOT SOLDER

CONNECTIONS!

STEP 5. POWER UP

Unscrew the battery box lid screws (2). Install 4 “Alkaline C” batteries in holder or snap

the battery clip directly to the optional 24 VAC converter.

BATTERY VERSION

Install four “Alkaline C” batteries provided into the battery holder.

After the batteries are installed, make the sensor connection on the driver board neatly

inside the battery box. Connect battery clip to battery pack. Two beeps indicate product

is ready to use. Use caution not to damage wires or components on electronic driver

board. See Fig. 5. Secure lid using screws. Do not use 9V battery.

HARDWIRE VERSION

Install CSA and/or UL approved Class 2 transformer or equiv-

alent in a convenient location or in a pipe chase.

(Do NOT install the transformer

inside the control box.)

With the power off, bring the 24 VAC supply wires to the box.

Connect the 24 VAC supply to the 060683A conversion kit. Connect the battery snap

of the hardwire converter to the driver board battery clip. Ensure snap does not touch

any conductive metal surface, then make the sensor connection on the control module

neatly inside the battery box. Do not remove battery snap from hardwire converter by

using a flat screwdriver, damage may result. Turn on power supply for the transformer.

STEP 6. PREPARE SINK AREA

Before connecting the spout cable – clean off counter and remove all objects

from the sink.

STEP 7. TIE SPOUT CABLE

Attach spout cable to box connector. Use tie wraps to secure spout cable to spout hose.

Your faucet is now ready for use (Fig. 2).

STEP 8. TEST FOR OPERATION

Test for operation. If faucet leaks from spout outlet: SHUT OFF WATER SUPPLIES.

Replace solenoid (2).

If faucet exhibits very low flow: A) Remove and clean spray outlet, or B) SHUT OFF

WATER SUPPLY. Clean or replace screen assembly (2). If unit does not work properly;

see Troubleshooting Guide on page 7.

INSTALLATION AND SET UP INSTRUCTIONS

Installation should be in accordance with local plumbing and electrical codes.

FLUSH ALL PIPES THOROUGHLY BEFORE INSTALLATION.

w w w . s p e c s e l e c t . c o m

Connect 20” braided hose to spout inlet. Clean deck/sink surface where faucet will be

mounted. Mount faucet to sink using nut(s) and washer(s) provided (Fig. 1). Installation

of the deck gasket (061031A) between the fixture and mounting surface is the recom-

mended assembly practice. Ensure that gasket is sitting flat on the deck and the fixture

is centered on the gasket. Mount the faucet to the sink using nut(s) and washer(s)

provided (RP6001). Tighten both nuts equally. Do not overtighten the nut or reposition

the fixture once installed, otherwise damage to the gasket may result. Cutting or trim-

ming of the gasket is not recommended.

NOTE: If the gasket is trimmed or not

installed, then use clear silicone sealant between the faucet and lavatory to

prevent water from leaking beneath lavatory.

3/8" O.D.

Copper

Inlet

Bypass

Adapter

Ferrule

Nut

Spout

Hose

Fig. 3

Fig. 4

Fig. 5

Trap

jacket of

cable in

hole for

strain

relief.

NOTE:

Always make

sure driver board is in

place before inserting

the battery pack. Use

caution not to pinch

wires or damage

components on the

electronic driver board.

1

2

7" (178 mm)

Max.

13" (331 mm) Max.

Tie Wraps

NOTE:

Entire connection can be placed

inside battery box if desired.

Fig. 2