11 -

English

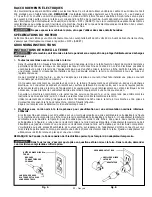

ADJUSTING THE HEAD ASSEMBLY

The head assembly (A) Fig. 12 contains the cutterhead,

Fig. 12

A

C

B

feed rollers, chip deflector and motor. Raising and

lowering the head assembly (A) controls the depth of

cut. To adjust the head assembly, rotate the cutterhead

lock handle (B) counterclockwise to unlock the

cutterhead. Turn the cutterhead adjusting handle (C)

clockwise to raise or counterclockwise to lower the

cutterhead (A). One revolution of handle (C) will move the

cutterhead up or down 1/16" (1.6 mm).

CUTTERHEAD LOCK

The cutterhead lock helps to eliminate snipe in the board

that is being planed. Snipe can also be eliminated by

butting boards end to end and feeding them through the

planer. Long boards should always be supported, when

feeding them through the planer to help eliminate snipe.

SCALE AND POINTER

A dual English/Metric scale (D) Fig. 13 and pointer (E) is

Fig. 13

F

E

D

located on the front of the machine. This scale indicates

the thickness of the finished workpiece. To adjust the

pointer (E), plane a piece of wood through the machine.

Measure the thickness of the workpiece. If an adjustment

is necessary, loosen the screw (F) and adjust the

pointer (E). Tighten the screw (F).

SPEED CONTROL

Change speeds only while the motor is

running. Do not change speeds while planing.

Make sure that the speed control is fully

engaged before feeding work material.

1. The 22-580 is a two-speed planer. The speed

Fig. 14

A

C

B

control knob (A) is shown in Fig. 14.

2. Use the “Dimensioning” speed (B) Fig. 14 with 60

cuts per inch to size the board.

3. Use the “Finishing” speed (C) Fig. 14 with 90 cuts

per inch to finish your workpiece.