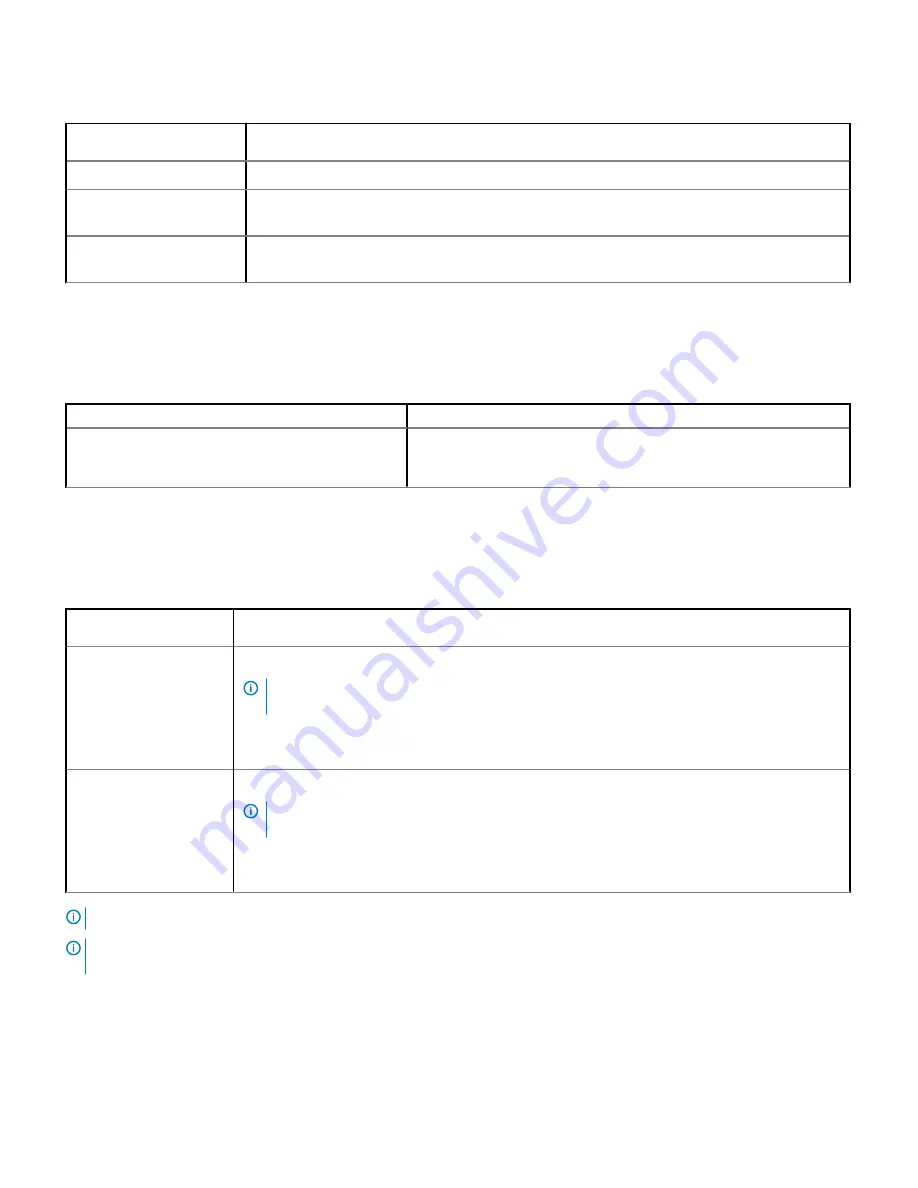

Table 30. Operating temperature derating specification

Operating temperature

derating

Specifications

Up to 35°C (95°F)

Maximum temperature reduces by 1°C/300 m (1°F/547 ft), above 950 m (3,117 ft).

35°C to 40°C (95°F to

104°F)

Maximum temperature reduces by 1°C/175 m (1°F/319 ft), above 950 m (3,117 ft).

40°C to 45°C (104°F to

113°F)

Maximum temperature reduces by 1°C/125 m (1°F/228 ft), above 950 m (3,117 ft).

Standard operating temperature

Table 31. Standard operating temperature specifications

Standard operating temperature

Specifications

Continuous operation

(For altitude less than 950 m or 3117 ft)

10°C to 35°C (50°F to 95°F)

with no direct sunlight on the equipment.

Expanded operating temperature

Table 32. Expanded operating temperature specifications

Expanded operating

temperature

Specifications

Continuous operation

5°C to 40°C at 5% to 85% RH with 29°C dew point.

NOTE:

Outside the standard operating temperature (10°C to 35°C), the system can operate

continuously in temperatures as low as 5°C and as high as 40°C.

For temperatures 35°C to 40°C, derate maximum allowable temperature by 1°C per 175 m (1°F per 319 ft)

above 950 m (3,1171 ft).

≤ 1% of annual operating

hours

–5°C to 45°C at 5% to 90% RH with 29°C dew point.

NOTE:

Outside the standard operating temperature (10°C–35°C), the system can operate down

to –5°C or up to 45°C for a maximum of 1% of its annual operating hours.

For temperatures between 40°C and 45°C, derate maximum allowable temperature by 1°C per 125 m (1°F

per 228 ft) above 950 m (3.117 ft).

NOTE:

When operating in the expanded temperature range, the performance of the system may be impacted.

NOTE:

When operating in the expanded temperature range, ambient temperature warnings may be reported on the LCD panel

and in the System Event Log.

Expanded operating range

•

The operating temperature is specified for a maximum altitude of 950 m for expanded operating range.

62

Technical specifications