1 – 84

Chapter 1 Troubleshooting

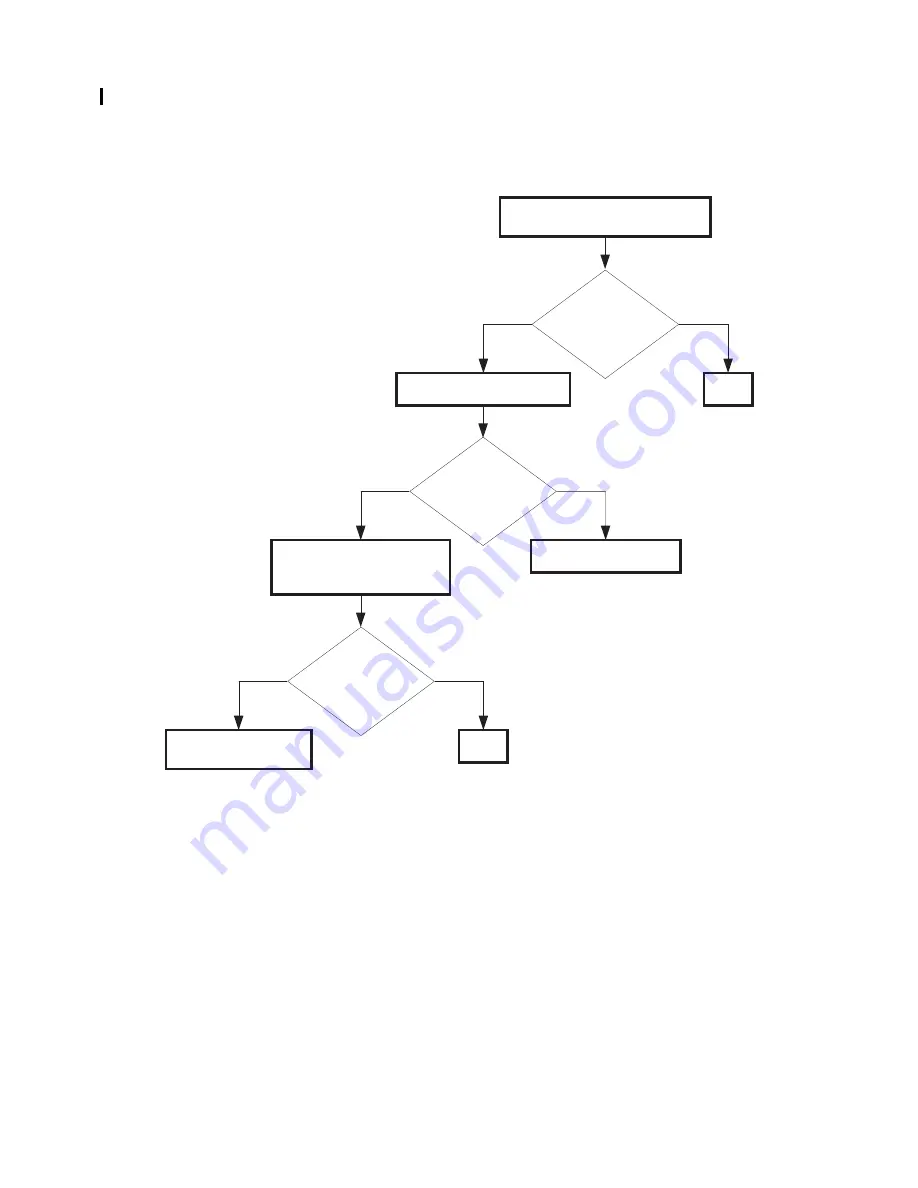

FIP-48 Imaging Drum 091-912/CRUM ID 093-965

Replace the PHD ASSY.

No

Yes

Possible causative parts:PHD ASSY (PL6.1.1)

PWBA MCU (PL9.1.16)

Checking the PHD ASSY installation

Reseat the PHD ASSY.

Does the error still

occur when turning

on the power?

Checking the PHD ASSY type

Is the PHD ASSY

installed the 5110CN?

No

Yes

Does the error still

occur when turning

on the power?

No

Yes

END

Checking after replacing the

PHD ASSY

Replace the PHD ASSY.

END

Replace the PWBA

MCU. (RRP9.7)

Summary of Contents for 5110cn - Color Laser Printer

Page 1: ...Dell 5110cn Service Manual 12 Nov 2007 ...

Page 11: ...Intro 9 4 5 6 Caution label regarding Print Head Ida_Sec00_008FA ...

Page 17: ...Chapter 1 Troubleshooting Chapter 1 Troubleshooting CONTENTS ...

Page 127: ...1 110 Chapter 1 Troubleshooting 3 Skew 4 Linearity 5 Magnification Error ...

Page 178: ...Chapter 2 Operation of Diag Chapter 2 Operation of Diag CONTENTS ...

Page 255: ...3 5 Chapter 3 Removal and Replacement Procedures RRPs Blank Page ...

Page 263: ...3 13 Chapter 3 Removal and Replacement Procedures RRPs Blank Page ...

Page 303: ...3 53 Chapter 3 Removal and Replacement Procedures RRPs Blank Page ...

Page 316: ...3 66 Chapter 3 Removal and Replacement Procedures RRPs RRP3 10 Blank Page ...

Page 317: ...3 67 Chapter 3 Removal and Replacement Procedures RRPs RRP3 10 Blank Page ...

Page 320: ...3 70 Chapter 3 Removal and Replacement Procedures RRPs RRP3 12 Blank Page ...

Page 321: ...3 71 Chapter 3 Removal and Replacement Procedures RRPs RRP3 12 Blank Page ...

Page 334: ...3 84 Chapter 3 Removal and Replacement Procedures RRPs RRP4 4 Blank Page ...

Page 335: ...3 85 Chapter 3 Removal and Replacement Procedures RRPs RRP4 4 Blank Page ...

Page 361: ...3 111 Chapter 3 Removal and Replacement Procedures RRPs Blank Page ...

Page 365: ...3 115 Chapter 3 Removal and Replacement Procedures RRPs Blank Page ...

Page 373: ...3 123 Chapter 3 Removal and Replacement Procedures RRPs Blank Page ...

Page 379: ...3 129 Chapter 3 Removal and Replacement Procedures RRPs Blank Page ...

Page 435: ...3 185 Chapter 3 Removal and Replacement Procedures RRPs Blank Page ...

Page 441: ...3 191 Chapter 3 Removal and Replacement Procedures RRPs RRP9 1 Blank Page ...

Page 457: ...3 207 Chapter 3 Removal and Replacement Procedures RRPs RRP9 7 Blank Page ...

Page 475: ...Chapter 5 Parts List Chapter 5 Parts List CONTENTS ...

Page 482: ...5 7 Chapter 5 Parts List Blank Page ...

Page 495: ...5 20 Chapter 5 Parts List PL4 2 Retard Regi assy 2 2 Illustration ...

Page 497: ...5 22 Chapter 5 Parts List PL5 1 Chute Assy In Out 1 4 Illustration ...

Page 499: ...5 24 Chapter 5 Parts List PL5 2 Chute Assy In Out 2 4 Illustration ...

Page 503: ...5 28 Chapter 5 Parts List PL5 4 Chute Assy In Out 4 4 Illustration ...

Page 509: ...5 34 Chapter 5 Parts List PL7 2 Development 2 2 Illustration ...

Page 511: ...5 36 Chapter 5 Parts List PL8 1 Drive Illustration 1 3 3 2 P481 P491 Ten05015KA ...

Page 517: ...5 42 Chapter 5 Parts List Blank Page ...

Page 528: ...6 9 Chapter 6 Principles of Operation Blank Page ...

Page 540: ...6 21 Chapter 6 Principles of Operation 3 1 2 Reference diagram ...

Page 542: ...6 23 Chapter 6 Principles of Operation Blank Page ...

Page 558: ...6 39 Chapter 6 Principles of Operation 3 8 2 Reference diagram ...

Page 588: ...7 7 Chapter 7 Wiring Diagrams and Signal Information Blank Page ...