V0606, 6.10

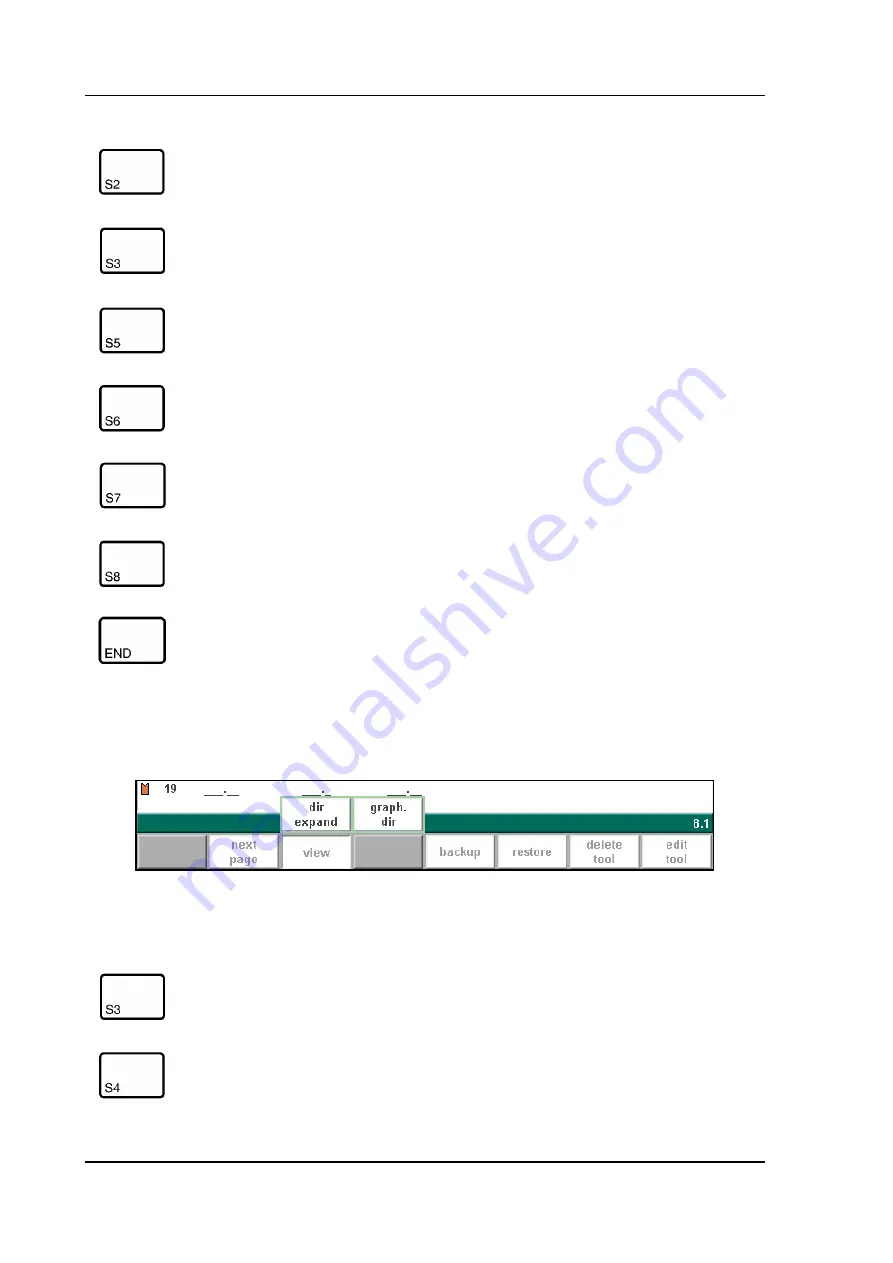

When the function key ‘View’ has been pressed a new, temporary button bar appears with

additional softkeys:

6.k

next page

To select the next page within the several pages of the die

library.

view

Button to select one of the possible viewing modes:

- dir. expand

- graph. dir.

backup

Save tools from library to disk.

restore

Load tools from disk into the control.

delete tool

Remove tool from library.

edit tool

To edit the tool drawing or check the die data.

To return to the program menu.

Function keys:

dir. expand

Select the normal view of the tool collection. This is the

standard setting.

graph. dir

To get a graphical overview of the tools as available in

the library including main dimensions of the tool.

Function keys:

Summary of Contents for DA-65W

Page 1: ...Delem Manual version V0606 DA 65W Reference Manual Operation of Version V2 ...

Page 6: ...V0606 0 6 ...

Page 50: ...V0606 2 30 ...

Page 75: ...Delem V0606 5 5 5 e ...

Page 78: ...V0606 5 8 ...

Page 86: ...V0606 6 8 6 i ...

Page 100: ...V0606 6 22 ...

Page 144: ...V0606 10 6 Functions screen 10 d Graphical visualisation 10 e ...