CAUTION

:

When you intend on changing speed, continue pedalling normally without

forcing, push the gear changer switch until the chain is in place on the chosen

crown

or spindle, if your gear changers are not indexed.

Each clog on the switch corresponds to a position on the spindles. If the chain

tends not to go up or down quickly on the spindle, stretch the cable turning the

adjustment cylinder located on the switch all the gear changer, anticlockwise.

If the chain tends not to go up or down too quickly, turn at the cylinder clockwise.

The spindle must be changed fluidly

5/Bearing adjustment

The fork is responsible for holding the front wheel of your bicycle. The headset is

the bearing system, which allows the steering of your bike by the rotation of the

fork, the stem and the handlebar.

There are several areas on your bicycle containing bearings that must be adjusted

and/or lubricated. Proper maintenance in these areas will insure longer bearing

life, and easier and safer riding of your bicycle.

Proper adjustment of these bearings requires special tools and knowledge. We

suggest these adjustments be made by a qualified repairman. Please see instruc-

tions below for checking if bearings need to be adjusted. If so, follow these

instructions:

1. Put the key washer onto the fork stem so it is down as far as possible. The small

tab inside the key washer must fit into the slot on the fork stem.

2. Thread the lock nut onto the fork stem by hand.

3. If there is front to rear play in the headset tighten the adjusting cone, then secu-

rely tighten the lock nut

4. To check the headset for proper tightness, bounce the front wheel on the

ground and turn the wheel from side to side. If the fork binds, it means that it’s

(too tight). If the fork shifts, it’s (too loose). Loosen the lock nut, readjust the

adjusting cone, and then re-tighten the lock nut.

DANGER

:

An over tightening of the stem-to-fork assembly bolts can make irreversible dama-

ges in the steering tube and may provoke an accident that can cause serious inju-

ries or death (can pull a blocking or a breakage of the movements, damage the

tube of direction…)

To avoid an over tightening, please respect the torques given in the “Assembly

and adjustments” chapter.

23

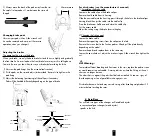

CONVENTIONAL GEAR CHANGER

The gear changer stroke (front and rear) should not be too large so as not to

derail the chain. "Both gear changers should be adjusted as explained below:

REAR GEAR CHANGER:

Turn the screws stop as shown in the diagrams to align

the rear gear changer roller below the large spindle

(when the turning wheel is at the slow speed) and

below the small spindle (when the turning wheel is at

the greatest speed).

The screw marked H prevents the chain from going

beyond the large spindle and the screw L prevents it

from going beyond the small spindle.

FRONT GEAR CHANGER:

Turn the screws stop as shown in the diagrams having

previously position the chain as shown. The space bet-

ween the chain and the guide should be between 0

and 0.5 mm.

The screw marked L prevents the chain from derailing

in the frame, the screw marked H prevents derailing in

the right-hand pedal.

SPEEDS IN THE HUB

Setting speeds in the hub is very simple. The

method is explained in detail in the manufacturer's

instructions. This system enables you change speeds

when stopped, without noise and instantly and you

cannot derail. Single speed bicycles or those fitted

with hubs do not have gear changers and need no

specific maintenance. The chain tension should

however be verified (it slackens over time). Too

strong tension in the chain could damage the effec-

tiveness of the bicycle amateurs in its lifespan

(pedalling hard). Too week tension may lead to fre-

quent derailments.

22

L

H

L

H