8

3.5 INITIAL START-UP:

a.

CLEANING: New units are wiped

clean with solvents at the factory to

remove any visible signs of dirt, oil,

grease, etc. remaining from the

manufacturing process, then coated

lightly with oil. Wash thoroughly with

hot, soapy water to remove any film

residue and dust or debris before food

preparation, then rinse out and wipe

dry. Wash also any accessories

shipped with the unit. Close the drain

valve completely and remove the

crumb screen. Make sure the screws

holding the thermostat and limit

control sensing bulbs into the vessel

are tight.

b.

HEATING THE VESSEL: This step

checks heater element operation, initial

thermostat calibration, and cleans the

vessel for initial food production.

1.

Fill the fryer vessel with hot or

cold water to the oil level line

scribed in the back of the tank.

2.

Set the thermostat/temperature

controller dial to 100°C/220°F, just

above that of boiling water.

3.

Toggle the power switch “ON”. The

heater elements will begin heating.

4.

When the water starts to boil, turn

the dial to below 99°C/210°F.

The elements will turn off and the

water will stop boiling.

5.

When satisfied that the heaters

and thermostat operate properly,

drain the vessel of water and dry

thoroughly. Refill fry vessel with

shortening as directed in section

3.6, Final Preparation.

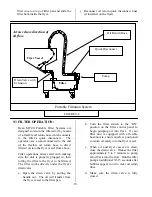

3.6 FINAL PREPARATION:

a.

When using liquid shortening

(cooking oil), fill the fryer to the “oil

level” line scribed into the back of the

fryer vessel.

b.

When using solid shortening, either

melt it first, or cut into small pieces

and pack into cool zone (bottom) of

the frying vessel. Be careful to not

leave any air spaces or disturb the

sensing bulbs. Melt shortening by

turning the heaters “ON” for about

five or ten seconds, “OFF” for a

minute, repeating cycle until

shortening is melted. If oil starts to

smoke while melting this way,

shorten the “ON” cycle and lengthen

the “OFF” cycle. Smoke shows that

you are scorching the shortening and

cutting its useful life.

NOTE:

Never melt a solid block of shortening

by setting it in the vessel or on top of the

heating elements. This is unsafe, inefficient,

and dangerous.

c.

When the fryer vessel is filled and the

shortening melted, replace the crumb

screen over the heater elements.

d.

Before starting operation, turn the

temperature controller to the probable

working temperature; wait for the

temperature to stabilize then check

with a high-quality immersion

thermometer.

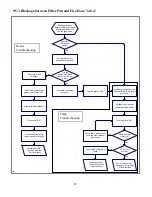

Figure 3-3

Power Switch

Temperature Controller