10

CAUTION

WHEN FILTERING, NEVER LEAVE THE

FILTER UNATTENDED. ALWAYS

POINT THE FLEXIBLE OIL RETURN

HOSE NOZZLE DOWN INTO THE FRY

VESSEL TO PREVENT THE SPRAYING

OF HOT OIL WHICH MAY CAUSE

SEVERE BURNS.

c. When the fryer is not in use, the

thermostat should be set lower than that

used during cooking.

4.3

TURN ON PROCEDURES:

a.

If fryer is empty, pour enough frying

compound into the vessel to fill the

vessel to the "oil level” line scribed on

the rear wall. If solid shortening is to

be used, melt enough in a separate

container to cover the heating elements

in the bottom of the vessel, then melt

the rest in the vessel by turning power

switch off and on.

b.

Turn the power switch on; set

temperature controller to 177°C

(350°F). In less than 30 minutes, the

frying compound temperature will

stabilize and be ready for production.

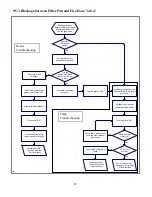

4.4 FILTERING:

a.

General: Filtering the frying

compound assures a better taste to the

food being prepared, minimizes

flavors being transferred from batch to

batch, and increases frying compound

lifespan.

Filter the frying compound at least

once daily or more frequently if

cooking is heavy.

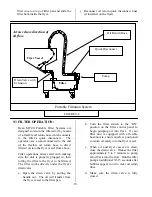

b.

Prior to filtering, align the filter unit

with the drain valve. Attach the drain

valve extension to ensure frying

compound flows into the filter unit

safely.

c.

If using solid shortening, clear return

lines before turning off the filter motor

and hang any flexible lines up to drain.

As it cools, solid shortening solidifies

and clogs lines.

d.

For more detailed information

concerning filtration, review the

operator's manual shipped with your

filter unit or read Chapter 9 of this

manual.

4.5

CLOSING:

When closing at night, filter

oil in all fryers and drain the filter lines.

Cover the open tanks of oil. Turn power

switch “OFF”.

4.6 SHUTDOWN:

When shutting down for

periods longer than overnight, drain the

frying compound and clean the vessel

thoroughly. Either discard the frying

compound or return it filtered to the vessel

and then cover it. Turn both the power switch

and temperature controller “OFF”.