2

2. PRE-INSTALLATION

GENERAL:

Installation of any heavy-duty electrical

appliance should be made by a licensed

electrician.

STANDARDS:

Installation must be planned in accordance with

all applicable state and local codes, taking into

account the following standards:

a) Nat'l Electrical Code ANSI/NFPA

#70-1984:

American National Standards Institute

1430 Broadway

New York, NY 10018

b) NFPA Standards #96 and #211:

National Fire Protection Association

470 Atlantic Avenue

Boston, MA 02110

CAUTION

Local building codes will usually not permit a

deep fat fryer with its open tank of hot oil to be

installed beside an open flame of any type,

whether a broiler or the open burner of a range.

Check local codes before beginning installation.

AIR SUPPLY & VENTILATION:

The area around the appliance must be kept

clear to avoid obstruction to the flow of

ventilation air as well as for ease of

maintenance and service. Under no conditions

is the interior of the fryer's cabinet to be used

for storage.

a) Means must be provided for any

commercial heavy-duty cooking

appliance to exhaust cooking vapors to

the outside of the building.

b) Filters and drip-throughs should be part

of any industrial hood, but consult local

codes before constructing and installing

any hood.

3. RECEIVING &

INSTALLING THE FRYER

UNPACKING:

Check that the container is upright. Use

outward prying - no hammering - to remove the

carton. Check the fryer(s) for visible damage; if

such damage has occurred, do not refuse

shipment, but contact the carrier and file the

appropriate freight claims. Do not contact the

factory, as the responsibility for shipping

damage is between the shipper and the dealer

or end-user.

Remove, unwrap, wash, and temporarily set

aside any accessories shipped in the fryer

vessel. These may include:

Basket hanger with baskets

Wire crumb screen

Goofer rod (clean-out rod)

Drain pipe extension

Lifters, scoops

Vessel cover

Teflon cleaning brush

Legs

LEGS:

Legs should be installed near where the

appliance is to be used. After unpacking, raise

the unit about a foot to permit the legs to be

screwed into their couplings, and lower it gently

to keep any undue strain from the legs and

internal mounting hardware. It is strongly

recommended that a pallet or lift jack be used

rather than tilting.

POSITIONING:

Do not push against any of the edges of the unit

in an attempt to adjust its position. Lift it slightly

and place it where it is to be installed. Although

all metal parts are deburred during

manufacture, accidents could occur if the fryer

(or a line-up) should move suddenly while being

pushed into position by hand. Pushing a unit

(rather than using a lift jack) also increases the

probability of bending the leg spindles or the

internal coupling connectors.

Summary of Contents for 1414E

Page 11: ...8 PARTS LIST COOL ZONE ELECTRIC FRYERS MODELS 714E 1414E 1818E 2020E ...

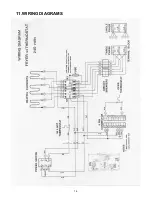

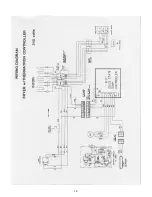

Page 17: ...14 11 WIRING DIAGRAMS ...

Page 18: ...15 ...

Page 19: ...16 ...

Page 20: ...17 ...