13

4.3 Operating Principle

The Davey Peristaltic pump adjusts its dosage in proportion to the

demand. It will dose less if the displayed measure is near the set point. In

normal operation, the AS Series pump will increase its ‘non operational’

time period proportional to the required dosage demand. That is why the

device often has the pump off.

This is normal

.

Adjust the pH slowly to preserve the natural quality of your water.

After 30 minutes without pressing the keys, the backlight turns off to save

energy. A short press on

SET

or

CAL

turns it on again.

5. Maintenance

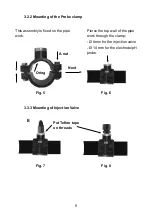

5.1 Replacement of the Peristaltic Tube

Follow steps 1 to 10 as shown

1.

5.

9.

Fig. 13

2.

6.

10.

3.

7.

4.

8.