Setup

18

5

DATECS

ЕP-2000

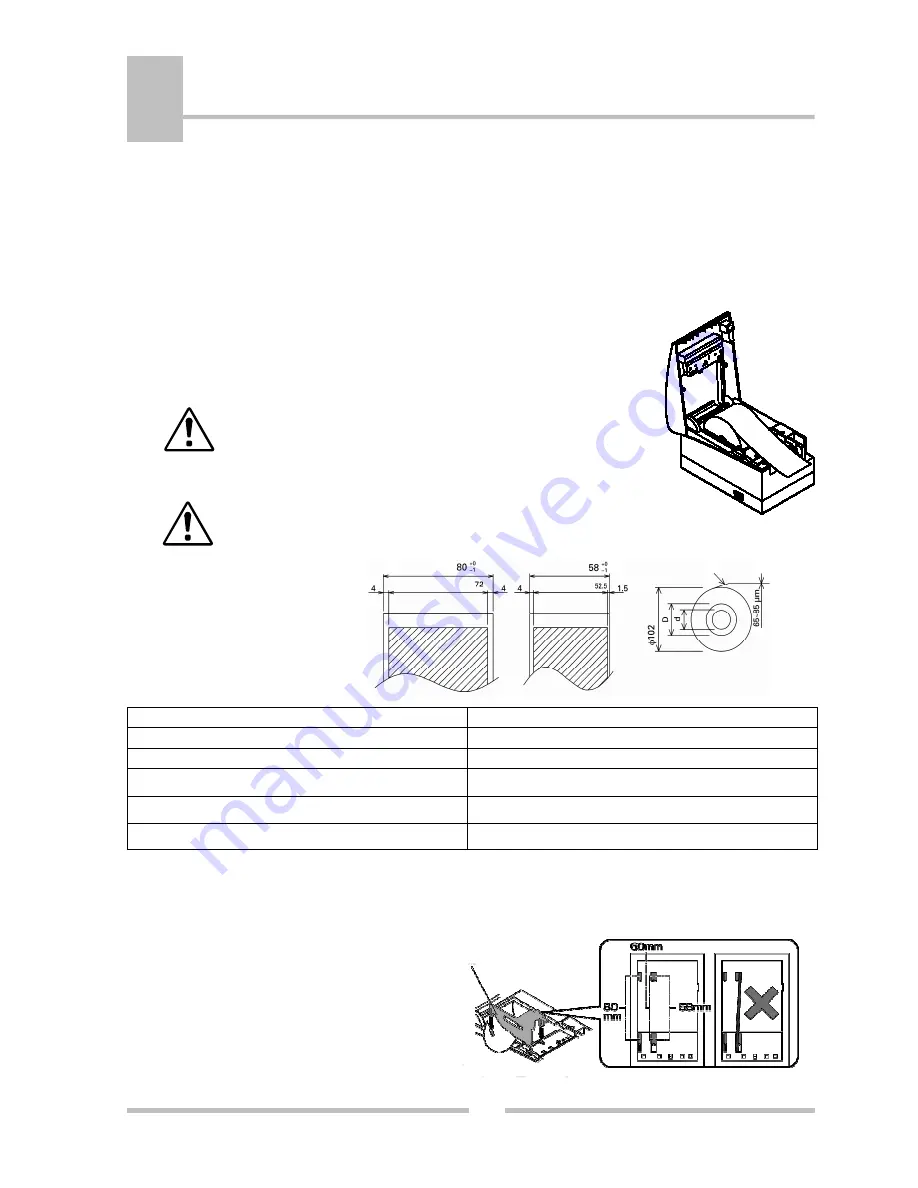

Loading/Replacing the paper roll

EP-2000

uses a roll thermal paper for printing. The width and diameter of the paper roll are

specified in the printer's technical spesification.

EP-2000

uses a drop-and-load design making paper loading easy and trouble free. To load

paper, simply lift up the paper cover latch and drop in the new roll as shown in the steps

below.

1.

Lift the cover open button

2.

Open the printer cover.

3.

Insert a new paper roll.

The thermal roll must be placed as shown in the figure

on the right – the thermal surface of the media must be

faced to the thermal head.

4.

Close theprinter cover until aclick can be heard.

Be sure to pull at least 12 mm or more of media above the top

of the printer before closing.

The paper roll recomended

parameters

Max. paper width, mm

80/58

Max. print width, mm

72/52.5

Max. paper roll diameter, mm

102

Paper thickness,

m

m

65-85

Core outer diameter (D), mm

18 (for 65-75

m

m) / 32 (for 75-85

m

m)

Core inner diameter (d), mm

12 (for 65-75

m

m) / 25.4 (for 75-85

m

m)

Partition for paper roll

Put the partition for 58/60 mm paper roll cirrectly, as shown in the picture below.

partition