38

E-4203/E-4204/E-4304

FRI AUGUST 024, 2001 19:29 236

VER: E4204 - 04.06 08/24/01

BOOT 83-2329-04A

CODE 83-2325-04F

FONT 83-2337-01A

CPLD 592157-01C

INTERNAL FLASH MODULE PRESENT

SYSTEM RAM CHECKS____ GOOD

SYSTEM RAM SIZE___ 2015 KBYTES

SYSTEM RAM AVAIL__ 1244 KBYTES

REG POWER SUPPLY__ YES

INPUT VALUES

PAPER_____________ 255

DARKNESS__________ 131

TRAN______________ 255

REFL______________ 149

RIBN______________ 87

TEMP______________ 48

VOLT______________ 223

CONFIGURATION

DIRECT THERMAL

SERIAL PORT SELECTED

19.2; 8BITS

EDGE

CONT FORM LENGTH__ 0

PRESENT ADJUST____ 127

SOP ADJUST________ 127

TOF LOW___________ 0 0

TOF DELTA_________ 10 10

TOF GAIN__________ 12 10

OOS MAXVOLT_______ 3 3

LABEL ALIGNMENT___ NO

ALIGN LENGTH______ 100

STOP LOCATION_____ HOST

COUNTER INFORMATION

ABSOLUTE VALUES 6-18-2001

LENGTH____ 773 INCHES

TIME______ 20 HOURS

RESETTABLE VALUES 6-22-2001

LENGTH____ 576 INCHES

TIME______ 10 HOURS

MEMORY CONFIGURATION

INTERNAL MODULE______ 15

SCALABLE FONTS_______ 32

LABEL SIZE 0416:02157 IN

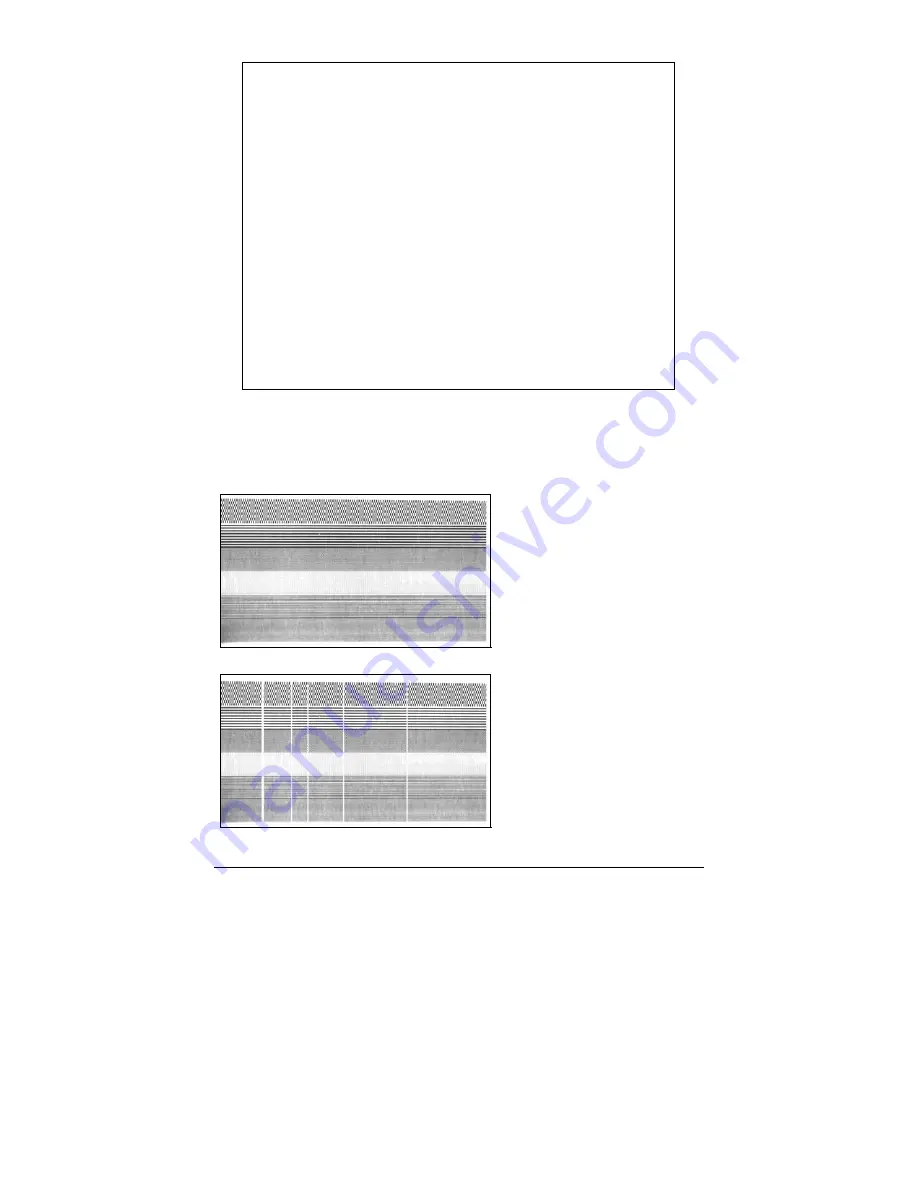

The second label printed is the Dot Check Label. This label is used to

test the condition of the printhead, as shown below:

Good Dot Check Label:

Even pattern consistency

indicates that the printhead

is operating normally.

Faulty Dot Check Label:

Streaks in the patterns

indicate a dirty or faulty

printhead (see Chapter 5).

Summary of Contents for E Class E-4203

Page 1: ...E 4203 E 4204 E 4304 w USB Operator s Manual ...

Page 2: ......

Page 6: ......

Page 10: ...iv ...

Page 28: ...18 E 4203 E 4204 E 4304 ...

Page 66: ...56 E 4203 E 4204 E 4304 ...

Page 82: ...72 E 4203 E 4204 E 4304 ...

Page 88: ...78 E 4203 E 4204 E 4304 ...

Page 92: ...82 E 4203 E 4204 E 4304 ...