This product is covered by one or more of the following patents.

European Patent 851,211 B1; 1,111,690 B1; 1,148,346 B1; 1,209,487 B1.

Italian Patent IT 1,321,772.

S5N-PL/ML SERIES

INSTRUCTION MANUAL

IEC 60825-1

“Caution –

use of controls or adjustments or performance of

procedures other than those specified herein may result in hazardous

radiation exposure

”

CONTROLS

OUTPUT LED (S5N-

PL/ML…B01/C01/F01)

The y ellow LED ON indicates that the N.O. (normally

open) output status is closed.

POWER ON LED

The green LED indicates that the sensor is operating.

TRIMMER (S5N-

PL/ML…B01/C01/F01)

The trimmer can be used to adjust sensitiv ity ; the

operating

distance

increases

turning

the

trimmer

clockwise.

WARNING: The trimmer rotation is limited to 270° by a

mechanical stop.

Do not apply excessive torque when adjusting (max 40

Nmm).

INSTALLATION

S5N-PL:

The sensor can be fixed by means of the M18x1 threaded body

through a

18 mm hole, using the specific washer and the two CH.24

nuts enclosed (1.5 Nm maximum tightening torque).

Alternatively, the sensor can be mounted through the two housing’s holes

using two screws (M3x22 or longer) and washer.

Amongst the various possible solutions, we suggest to choose the

combination that offers the best visibility of the signalling LEDs and the

easiest access to the trimmer.

22 mm nuts, h=8 mm, (2 Nm maximum tightening torque) are available to

guarantee an improved torque.

S5N-ML:

The sensor can be fixed by means of the M18x1 threaded body

through a

18 mm hole, using the two CH.24 nuts enclosed (22 Nm

maximum tightening torque).

For both plastic version and metallic version are

available various orientable fixing brackets to

ease the sensor positioning (please refer to the

accessories listed in the general catalogue).

The operating distance is measured from the

front surface of the sensor lens.

In case of lateral translation, the object must

move as indicated in the figure.

CONNECTIONS

The connections are compliant to the EN 60947-5-2 standard.

S5N-

PL/ML…B01/C01/F01

+

10 … 30 Vdc

N.C. OUTPUT

BROWN

1

WHITE

2

BLACK

4

BLUE

3

N.O. OUTPUT

0 V

S5N-

PL/ML…G00

+

10 … 30 Vdc

TEST +

BROWN

1

WHITE

2

BLACK

4

BLUE

3

NOT USED

0 V

M12 CONNECTOR

2

3

1

4

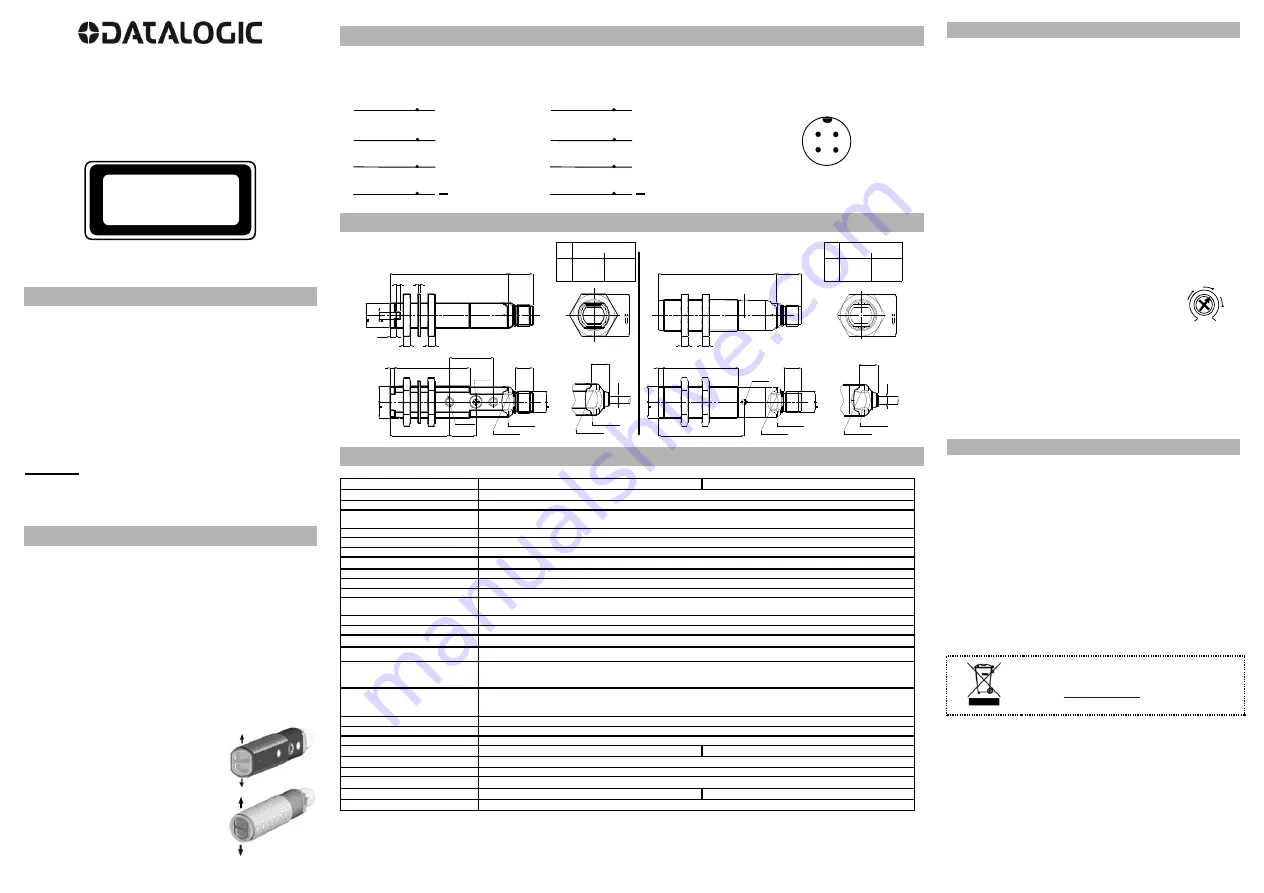

DIMENSIONS

24

=

N°.2 Ø3.8

4

=

2.5

=

4

=

3

.8

2

POWER ON LED

mm

10

Ø4

TRIMMER

OUTPUT LED

OUTPUT LED

POWER ON LED

57

42

24

G version

L

X

X1

M O D E L S

B/C/F version

67

43

34

L

X1

X

CABLE VERSION

=

2.5

4

4

TRIMMER

=

24

14.5

25

15

M

1

8

x1

14

3.5

M12

10

1.5

49

M

1

8

x1

10

M12

S50-PL VERSIONS

S50-ML VERSIONS

14.5

POWER ON LED

OUTPUT LED

POWER ON LED

OUTPUT LED

10

Ø4

CABLE VERSION

G version

57

38

L

X

67

43

B/C/F version

M O D E L S

L

X

TECHNICAL DATA

S5N-PL PLASTIC VERSIONS

S5N-ML METALLIC VERSIONS

Power supply:

10 … 30 Vdc (limit values)

Ripple:

2 Vpp max.

Current consumption

(output current excluded):

35 mA max. (mod.B01/C01/F01)

30 mA max (mod.G00)

Outputs:

N.O. and N.C.; PNP or NPN

(short-circuit protection)

Output current:

100 mA max.

Output saturation voltage:

2 V max.

Response time:

333

s

Switching frequency:

1,5 kHz

Indicators:

OUT PUT LED (YELLOW) (mod.B01/C01/F01) / POWER ON LED (GREEN)

Setting:

sensitivity trimmer (mod.B01/C01/F01)

Operating mode:

LIGHT mode on N.O. output / DARK mode on N.C. output (mod.C01)

DARK mode on N.O. output / LIGHT mode on N.C. output (mod.B01/F01)

Operating temperature:

-

10 … 50 °C

Storage temperature:

-

25 … 70 °C

Insulating strength:

500 Vac 1 min., between electronics and housing

Insulating resistance:

>20 M

500 Vdc, between electronics and housing

Operating distance (typical

values):

B01: 0.1…16 m on R2

C01: 0…35 cm

F01/G00: 0…60 m

Emission type:

RED LASER: Class 1 IEC 60825-1 (2014) (mod.B01/C01/G00)

Class 1 CDRH 21 CFR PART 1040.10 (mod.B01/C01/G00)

Max. power

1 mW; Pulse = 5

S;

= 645…660nm; Frequency

25 kHz

Ambient light rejection:

according to EN 60947-5-2

Vibrations:

0.5 mm amplitude, 10 … 55 Hz frequency, for every axis (EN60068-2-6)

Shock resistance:

11 ms (30 G) 6 shock for every axis (EN60068-2-27)

Housing material:

PBT

Nickel plated brass

Lens material:

PMMA

Mechanical protection:

IP67 Metal versions type 1 enclosure

Connections:

2 m cable

4 mm / M12 - 4 pole connector

Weight:

75 g. max. cable vers./25 g. max. connector vers.

110 g. max. cable vers./60 g. max. connector vers.

AtEx 2014/34/EU

II 3D EX tc IIIC IP67 T 85°C

SETTING

Setting of S5N-

PL/ML…B01

Position the sensor and reflector on opposite sides.

Turn the sensitivity trimmer to the maximum position.

Moving the sensor both vertically and horizontally, determine the power

ON and OFF points of the OUTPUT LED and then mount the sensor in

the middle of the points defined.

If necessary reduce sensitivity in order to detect very small targets.

In order to improve alignment, repeat the procedure detailed above whilst

progressively reducing the sensitivity.

Setting of S5N-

PL/ML…F01/G00

Position the sensors on opposite sides.

Turn the sensitivity trimmer to maximum: moving the sensor both

vertically and horizontally, determine the power ON and OFF points of the

OUTPUT LED and then mount the sensor in the middle of the points

defined.

If necessary, reduce sensitivity using the trimmer, in order to detect very

small targets. In order to improve alignment, repeat the procedure

detailed above whilst progressively reducing the sensitivity.

Setting of S5N-

PL/ML…C01

Turn the sensitivity trimmer to minimum: the OUTPUT

LED is OFF.

Position the target to detect in front of the sensor.

Turn the sensitivity trimmer clockwise until the

OUTPUT LED turns ON

(Target detected state, pos.A).

Remove the target, the OUTPUT LED turns OFF.

Turn the sensitivity trimmer clockwise until the OUTPUT LED turns ON

(Background detected state, pos.B).

The trimmer reaches maximum if the background is not detected.

Turn the trimmer to the intermediate position C, between the two

positions A and B.

TEST FUNCTION (S5N-

PL/ML…G00)

The TEST input can be used to inhibit the emitter and verify that the

system is correctly operating.

The receiver output should switch when the test is activated while the

beam is uninterrupted.

The input activating voltage range is 10…30 Vdc.

Datalogic S.r.l.

Via S. Vitalino 13 - 40012 Calderara di Reno - Italy

T el: +39 051 3147011 - Fax: +39 051 3147205 - www.datalogic.com

Helpful links at www.datalogic.com:

Contact Us,

Terms and Conditions,

Support

.

For information about the disposal of Waste Electrical

and Electronic Equipment (WEEE), please refer to the

website at

© 2018 - 2020 Datalogic S.p.A. and/or its affiliates

ALL RIGHT S

RESERVED.

Without limiting the rights under copyright, no part of this

documentation may be reproduced, stored in or introduced into a retrieval

system, or transmitted in any form or by any means, or for any purpose,

without the express written permission of Datalogic S.p.A. and/or its

affiliates. Datalogic and the Datalogic logo are registered trademarks of

Datalogic S.p.A. in many countries, including the U.S.A. and the E.U. All

other trademarks and brands are property of their respective owners.

Datalogic reserves the right to make modifications and improvements

without prior notification.

826000373 Rev.D

MIN

MAX

A

B

C

CLASS 1 IEC 60825-1 (2014)

LASER PRODUCT

S5N-PL VERSIONS

S5N-ML VERSIONS