CP80 and CP80 Plus Service Manual

4-5

Troubleshooting Sensors

The purpose of this procedure is to determine if a sensor has failed or if the main

control board is not seeing the sensor properly. The first step in troubleshooting

a sensor is to determine if the sensor is changing from an active state to an

inactive state as a physical condition changes.

Because data from the laminator control board passes to the printer control

board via a serial port and then gets reported to Diagnostics, there is a

significant delay between a sensor transition and the sensor display in

Diagnostics.

1.

Verify that the sensor is fully plugged in to the control board. In some cases,

an unplugged sensor will be displayed as “active” in the Diagnostics

window.

2.

Using Diagnostics, observe the sensor status indicator as the sensor is

blocked and unblocked.

•

To test the ribbon index sensor, remove the ribbon cartridge and open

and close the swingarm. (Also verify that the reflector is in position on

the printhead.)

•

To test the magnetic stripe registration sensor, slide a card between the

sensor and the reflector on the rocker arm.

•

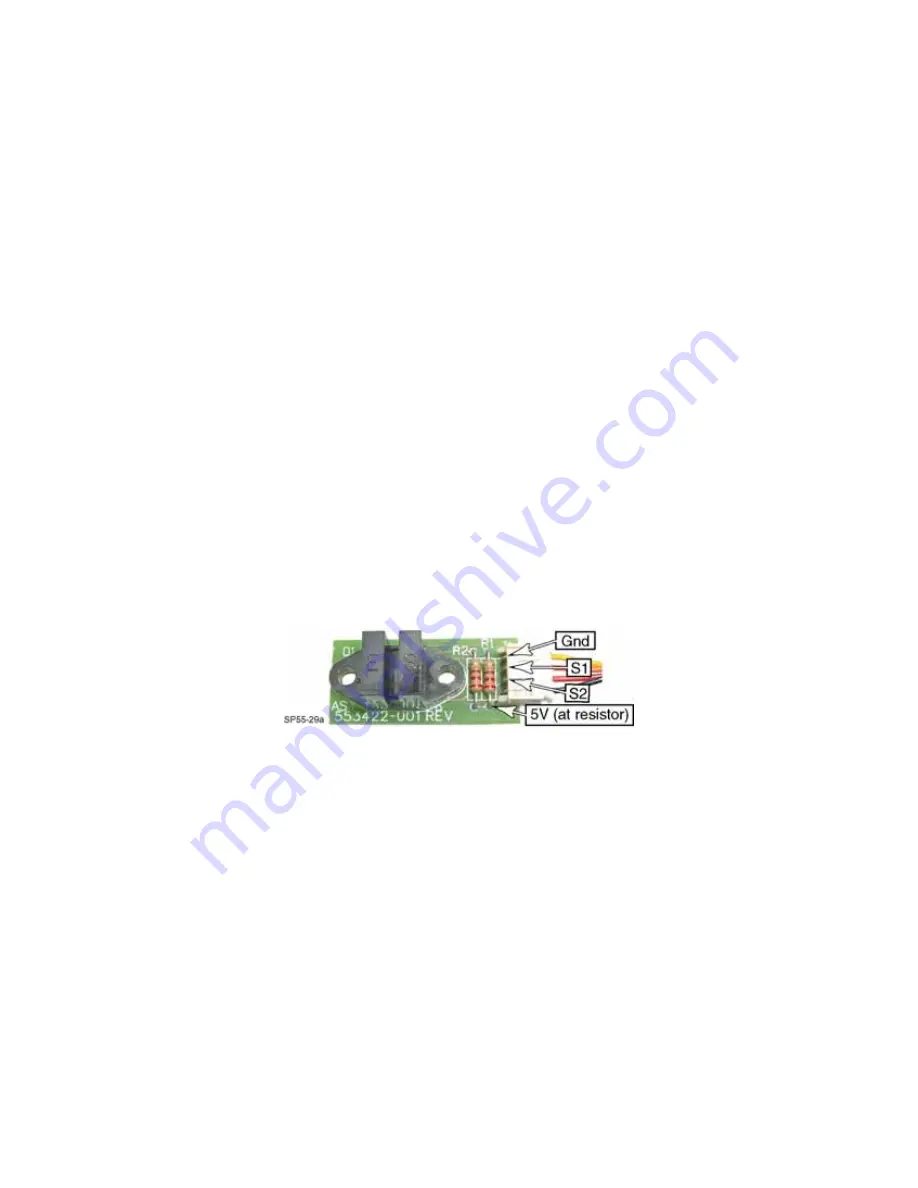

Because the ribbon motion sensor has two channels, the only way to

verify that both channels are functioning is with a voltmeter. Use the test

points in the figure below to test the sensor.

•

To test the laminator index and foil motion sensors (reflective-type) place

an object (such as a card) 1/8 to 1/4 inch in front of the sensor, but not

touching the sensor.

3.

Unplug the printer and swap the sensor with another sensor:

You cannot swap the ribbon motion sensor with any other sensor; it is not

compatible with any other sensor.

•

Because this is a test of the sensor, the original sensor does not need to be

removed. Simply unplug the original sensor from the control board and

plug in a replacement sensor.

•

If a spare sensor is not available, you can use an adjacent sensor from

within the printer. (Except for the ribbon motion sensor, all sensors are

electrically compatible.)

Summary of Contents for CP80 Plus

Page 1: ...Datacard CP80 and CP80 Plus Card Printers Service Manual May 2007 Part No 539490 002 Rev C ...

Page 14: ...1 4 Introduction ...

Page 17: ...CP80 and CP80 Plus Service Manual 2 3 Print Engine Functional Block Diagram ...

Page 18: ...2 4 Theory of Operation Laminator Functional Block Diagram ...

Page 22: ...2 8 Theory of Operation LCD Service Mode Menu Diagram ...

Page 52: ...2 38 Theory of Operation ...

Page 158: ...6 6 Removal and Replacement Print Engine Front Wire Routing Diagram ...

Page 159: ...CP80 and CP80 Plus Service Manual 6 7 Print Engine Duplex and Printhead Wire Routing Diagram ...

Page 160: ...6 8 Removal and Replacement Laminator Front Wire Routing Diagram ...

Page 161: ...CP80 and CP80 Plus Service Manual 6 9 Laminator Rear Wire Routing Diagram ...

Page 162: ...6 10 Removal and Replacement Power Supply Wire Routing Diagram ...

Page 163: ...CP80 and CP80 Plus Service Manual 6 11 Print Engine Cable Connection Diagram ...

Page 164: ...6 12 Removal and Replacement Laminator Cable Connection Diagram ...