2

Installation

PC Requirements

Use a PC that meets or exceeds the following:

A 32- or 64-bit processor, running at 2GHz or faster

4 GB or more memory (RAM) and at least 1 GB free space on the hard drive

One of the following operating systems:

Windows 10, 32- or 64-bit

Windows 8.1, 32- or 64-bit

Windows 7, 32- or 64-bit

Windows Server 2012, R2, 64-bit

Windows Server 2008, 64-bit

Ethernet network connection

Datacard® CardWizard® issuance software

Ethernet Requirements

The following network components are required:

An Ethernet network that uses the TCP/IP protocol and can run at 100 megabits per second,

also called 100base-T.

An Ethernet cable to connect the system to the network. (An Ethernet cable is not supplied

with the system.)

Electrical Requirements

The power supply is rated as follows:

The power supply detects the input voltage and works within the stated range.

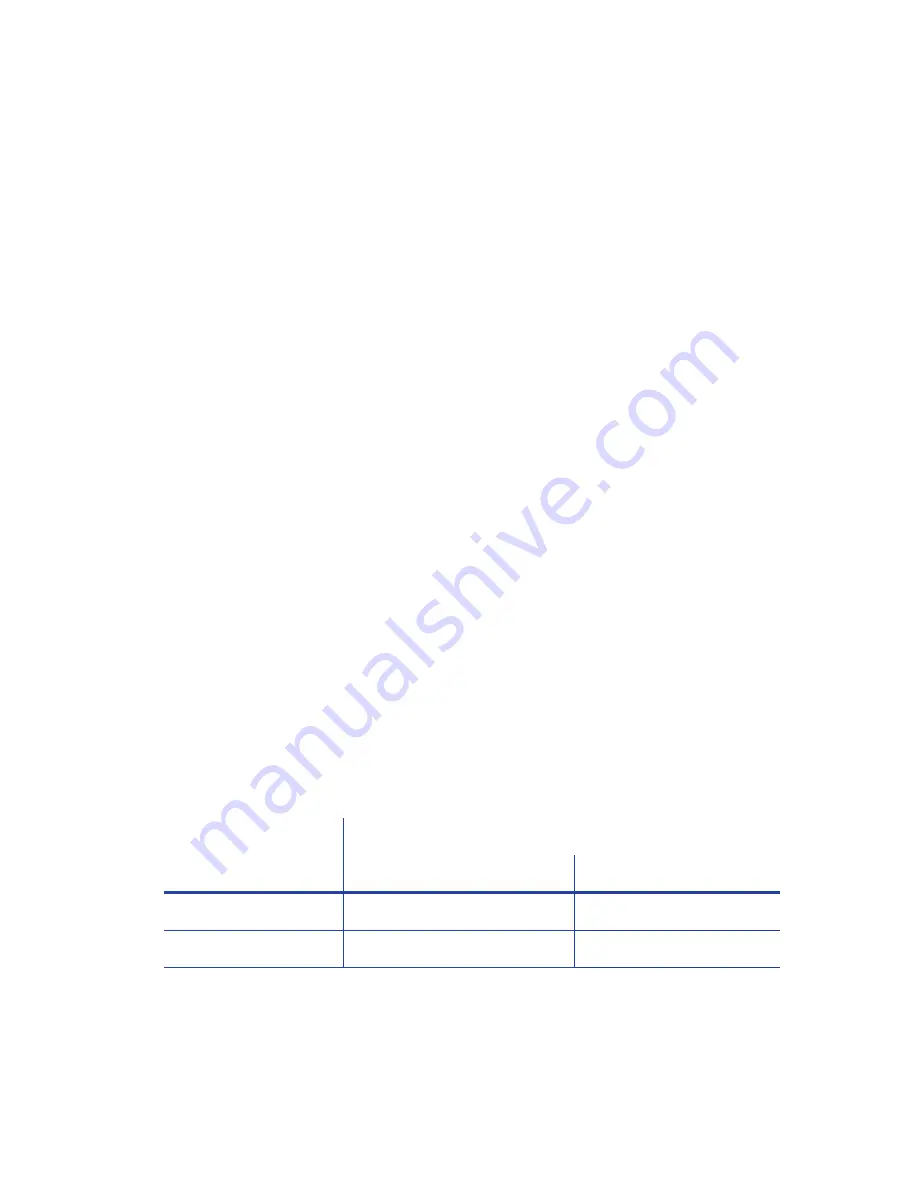

System Component

Electrical Requirements

Input

Output

Printer

110-240V/50–60Hz/1.5 Amp

24V/3.0Amp/72W

Embosser

110-240V/50-60Hz/3.5 Amp,

24V/10.42Amp/250W