19

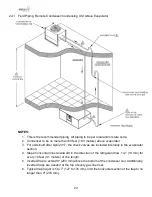

For air-cooled units built after April 2017, the discharge check valves are already installed inside the

evaporator section and do not need to be installed external to the unit. For units built before this date,

the check valves must be field supplied and installed externally to the evaporator section. If there is

doubt as to whether the check valve is already installed in the unit, look for it on the hot gas line close

to the exit point of the unit (see example picture below). The externally installed check valve should be

placed from six (6) to ten (10) feet (1.8 to 3.1 m) from the compressor.

NOTICE:

Picture of the check valve is only intended to show an example of a

common check valve installation. It may not represent your specific unit,

check valve size, location or orientation.

Figure 3 Typical Discharge Check Valve

The check valve will prevent flow from the condenser to the compressor during the off cycle.

The evaporator section ships with a nitrogen holding charge. Do not vent the evaporator until all

refrigerant piping is in place, ready for connection to the evaporator and condenser. The discharge,

suction and liquid lines need to be refrigerant grade copper and in accordance with local code. All

refrigeration piping should be installed with high temperature brazed joints. When brazing, a supply of

nitrogen gas needs to be fed through the refrigerant lines. Be sure to open the other end of the

refrigerant line to allow the nitrogen to bleed off and not pressurize the piping. Prevailing good

refrigeration practices should be employed for piping support, leak testing, dehydration and charging

the refrigerant circuits. During the installation, the lines should be capped off and filled with dry nitrogen

at the end of each day’s work or until the system is completed and sealed.

Data Aire recommends a silver/phosphorus/copper alloy with 5 to 15% silver be used to braze the

Summary of Contents for DA PA-04

Page 1: ......

Page 81: ...DAP IOM_10 2022 ...