18

•

Proper piping practices should be employed to ensure adequate oil return, even under

minimum load conditions with special consideration given to the size and proper slope of the

tubing coming from the evaporator. See section

information regarding line sizes.

•

Tubing returns from the evaporator should be designed so as not to trap oil and to prevent

oil and refrigerant migration back to the compressor during compressor off cycles.

Piping should be designed with adequate three-dimensional flexibility. It should not be in contact with

the surrounding structure unless a proper tubing mount has been installed. This protection proves

necessary to avoid excess vibration, which can ultimately result in connection or tube failure due to

fatigue or wear from abrasion. Aside from tubing and connection damage, excess vibration may be

transmitted to the surrounding structure and generate an unacceptable noise level within the structure

as well.

When piping, use copper tubing with appropriate supporting devices (supporting saddles, etc.). All field

piping must be installed according to local codes. Avoid piping runs through noise sensitive areas, such

as office walls and conference rooms.

Piping and to the ASHRAE Refrigeration Handbook for general, good practice refrigeration piping.

When installing piping on a horizontal surface, it is recommended that the pipes be mounted in a

horizontal plane rather than stacked one above the other.

Ensure that the tubing surfaces to be brazed are clean and that all burrs have been removed from the

ends of the tubes. Ensure that all loose material has been cleaned from inside the tubing before brazing.

Keep piping clean and dry, especially on units with R-410A refrigerant.

Split Air-Cooled Unit Piping

Air-cooled unit piping is crimped and brazed closed from the factory and contains a nitrogen holding

charge. Each installation requires field supplied refrigerant piping to a condenser.

2.13 Split Air-Cooled Unit Piping

for a guideline on sizing refrigerant lines. Standard

piping practices must be used to ensure proper oil return and efficient operation. The interconnecting

lines to the remote air-cooled condenser or condensing unit must be installed by a qualified refrigeration

mechanic. The ultimate responsibility for line size selection is that of the installing contractor or design

engineer. Data Aire does not assume this responsibility. The chart covers distances up to 200

equivalent feet (61 m). For installations beyond this distance, consult ASHRAE or similar references.

NOTICE:

Standard piping practice must be used to ensure proper oil return

and efficient operation. The interconnecting lines to the remote air-cooled

condenser or condensing unit must be installed by a qualified refrigeration

mechanic.

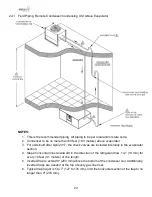

Discharge Lines

Discharge lines, also called hot gas lines, should be trapped at the top (inverted) and bottom, as well

as every 15 to 20 feet (4.6 to 6.1 m) of vertical rise. Discharge line check valves are required on all

installations, especially those where there are long pipe runs or cold climate.

Summary of Contents for DA PA-04

Page 1: ......

Page 81: ...DAP IOM_10 2022 ...