7

www.danvex.fi

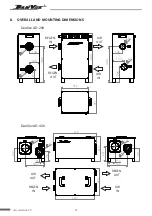

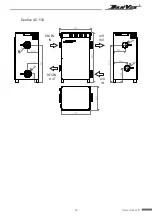

2.3

Construction

2.3.1

Hull

•

compact stainless steel frame construction for corrosion resistance and effective insulation

against condensation

;

•

removable panels providing access to internal components

;

•

well-designed layout and selection of units to ensure minimum head drop

.

2.3.2

Conveying air circuit

•

at the air inlet there is a filter class G3 with the possibility of cleaning

;

•

centrifugal high efficiency low noise fan

.

2.3.3

Regeneration air circuit

•

at the air inlet there is a filter class G3 with the possibility of cleaning

;

•

centrifugal, high-efficiency, low-noise, forward-curved fan

.

•

heating section using PTC heaters

.

2.3.4

Rotor

•

The rotor is the main part of the dryer. Its characteristics directly affect the performance

and operation of the dehumidifier. The rotor is made of a special heat- resistant composite

material. The composite material is a corrugated structure filled with a highly effective

desiccant, forming many small air flow channels, contacting the air with a large area

and increasing the dehumidification efficiency

.

2.3.5

Rotor drive

•

Rotation of the rotor at the desired speed can be achieved using an electric motor

with a geared motor and a belt drive. The belt is located on the outer rim of the rotor

and is driven by a geared motor pulley

.

•

The belt tensioner maintains proper belt tension to prevent belt slip page. The direction

of rotation of the rotor and the condition of the belt need to be checked regularly

.

2.3.6

Safety devices

•

Motor protection against overload and short circuit: fan motors for working and regeneration

air, rotor drive motor have overload and short circuit protection functions

.

•

Shutdown protection: When the dryer is switched off under normal conditions,

the regeneration fan continues to run until the regeneration heater and rotor have cooled

below

60°С.