18

www.danvex.fi

6.

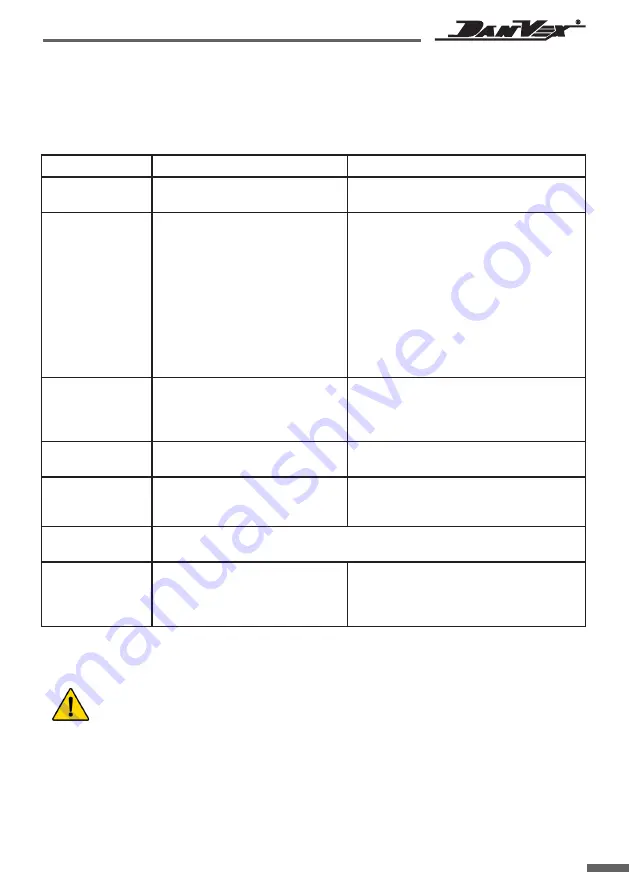

PREVENTION AND TROUBLESHOOTING

6.1

Frequency of inspection and maintenance

To prevent failure of units and assemblies of the dryer, it is necessary to periodically inspect

:

Knot

3-6

months

12

months

Filters

Filter cleaning.

If the filter soiled replace it.

Fan

Dust and debris in the cooling groove

on the surface of the motor housing

must be removed.

Check terminals of engine wiring to make

sure the wiring is not loose.

Check fan bearing lubrication

and add lubricating oil.

Check fan impeller for damage.

If there are signs of corrosion,

take immediate action.

Electric motor rotor

Check the drive belt for damage

and correct operation

Check motor wiring

and make sure wiring is not loose.

Check for signs of damage

and overheating.

Heater

Remove debris and dust from

the surface of the heater

Rotor

Check for signs of overheating and blockage.

Clean the dust from the surface of the rotor.

Seals

Check for signs of damage and displacement.

If there is wear or damage, then a replacement is required.

Sensors

of temperature

and humidity

Check the performance of all external

temperature and humidity sensors

and, if necessary, calibrate them

.

There is high voltage inside the block. Before any maintenance work,

check that the device is powered off.

There is a high temperature zone inside the unit (heating section of the regenerator)

that needs to be cooled down before maintenance.

Adjustment, maintenance and repair of the device must be carried out by qualified personnel.

Relevant personnel should be aware of the high temperature and high pressure inside the unit.