2

FRCC.EI.024.A1.02 © Danfoss Commercial Compressors 10/12

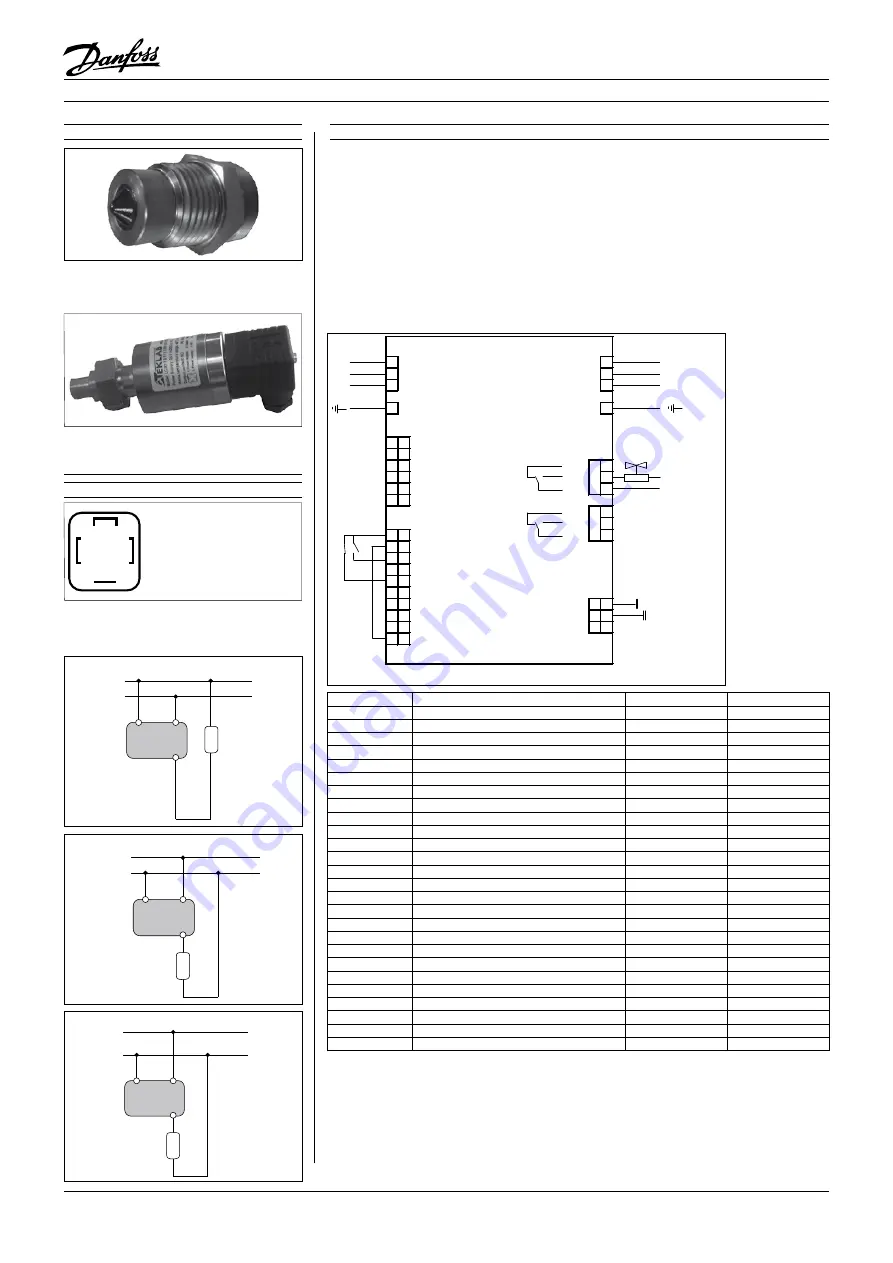

Basic connections

- Depending on the frequency converter

version, the physical position of individual

connectors may differ from below diagram.

- Always make sure that the compressor termi-

nals T1, T2, T3 are connected to the frequency

converter terminals 96, 97, 98 respectively.

- The compressor motor cable must be shielded

and the armoured part must be connected to

ground on both cable ends; at the side of the

compressor and at the side of the frequency

converter.

- Use an EMC cable gland for cable installation and

perfect grounding; The metallic terminal box of

the compressor has a paint-free surface around

the connection hole for better conductivity.

- A low pressure safety switch is mandatory

to avoid compressor vacuum operation.

- At start-up, verify that the compressor rotates

in the right direction and pumps.

230 V or 24V

~

2 A max

R

E

LA

Y

1

L1

91

L1

W

98

T3

L2

92

L2

V

97

T2

L3

93

L3

U

96

T1

95

PE

PE

99

39 39 Ana out COM

42 42 Ana out +

50 50 Ana out +10 V

NC

03

53 53 Ana in 0 ± 10 V

NO

02

54 54 Ana in 0 ± 10 V

COM

01

55 55 Ana in COM

NC

06

NO

05

12 12 +24V

COM

04

13 13 +24V

18 18 Dig in

19 19 Dig in

27 27 Dig in/out

29 29 Dig in/out

32 32 Dig in

N- RS485 69 69

33 33 Dig in

P+ RS485 68 68

20 20 Dig in COM

COM RS485 61 61

37 37 Dig in

R

E

LA

Y

2

C

D

S3

03

Legends:

Ana: Analogue

Dig: Digital

in:

Input

out: Output

COM: Common

NC: Normally-closed

NO: Normally-open

Open loop

Process loop

91, 92, 93:

3 Phase mains input

X

X

95:

Earth

X

X

39, 42

Analogue output

-

-

50:

Analogue output

-

-

53:

PLC+ (0 to 10 V)

X

-

54:

Sensor -

-

X

55:

PLC-

X

-

12:

HP/LP switch

X

X

12:

External On/Off (NO)

X

X

13:

Factory bridged to 37

X

X

13:

-

X

18:

External On/Off (NO)

X

X

19:

Digital input

-

-

27:

HP/LP switch (NC) / safety devices

X

X

29:

Digital input/output

-

-

32, 33

Digital input

-

-

20:

Digital input Common

-

-

37:

Factory bridged to 13

X

X

98:

To compressor terminal T3

X

X

97:

To compressor terminal T2

X

X

96:

To compressor terminal T1

X

X

99:

To compressor earth connection

X

X

02, 01:

Relay 1 to oil solenoid valve

X

X

06, 05, 04:

Relay 2

-

-

69, 68:

RS485 Bus

-

-

61:

RS485 Bus Common

-

-

The CDS303 frequency converter is factory pre-

set with parameters for the

open loop

control

principle. The

process loop

control principle

can be selected by changing parameters in the

«Quick menu».

Open loop

:

0 - 10 V control

Frequency converter in slave mode

Process loop:

4 - 20 mA control

Frequency converter under own PID controller

Oil level switch assembly

Electrical connections / Wiring

Install the screw-in optical part on oil level

switch port. (Factory preset for manifold version

VZH compressor.)

3

1

4

2

1: Power supply wire

2: Power supply wire

3: Output wire

4: Not used

Install the electrical part on optical part. Make

sure the cable outlet downside vertically

see at the correct diagram corresponding

to different power supply models for proper

wiring

1

OVDC

24VDC

2

3

Sensor

External

Load / Relay

24VDC MODEL

1

OVAC

24VAC

2

3

Sensor

External

Load / Relay

24VAC MODEL

1

N

L

2

3

Sensor

External

Load / Relay

230VAC MODEL

- : Optional connection

X : Mandatory connection

Instructions