4. Installation

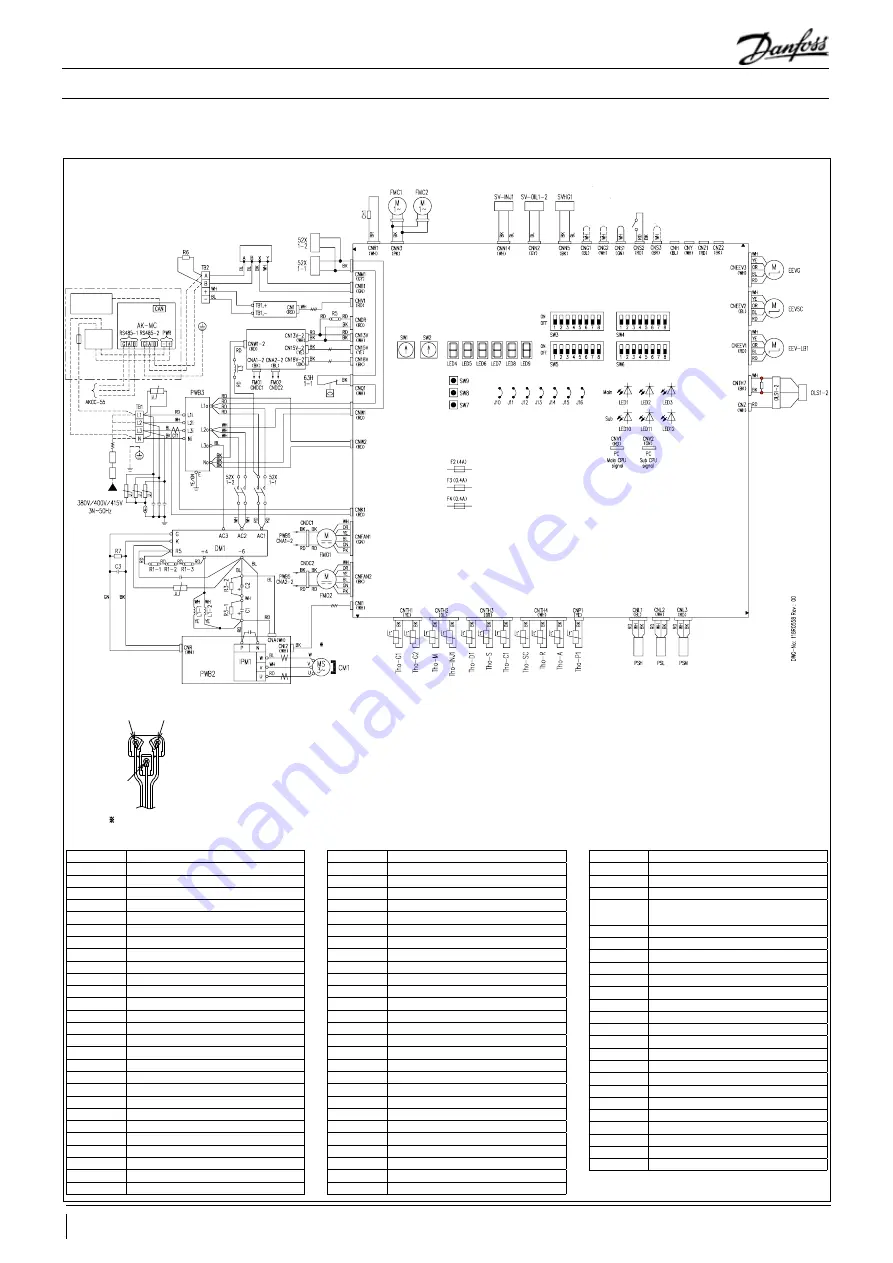

Wiring Diagram

Symbol

Name

C1,2

Electrolytic capacitor

C3

Filter capacitor

CH1

Crankcase heater

CM1

Compressor motor

CNA-Z

Connector

CT1

Compressor current

DM1

Diode module

EEVG

EEV for middle pressure receiver inlet

EEV-LB1

JEEV for liquid bypass

EEVSC

EEV for subcooling coil

F

Fuse

FMC1,2

Inverter cooling fan

FMO1,2

Fan motor

IPM1

intelligent power module

J10

Spare

J11,12

Power supply, voltage switching

J13

External input signal type switching

J14~16

Spare

L1-1,2

DC reactor

L3

Reactor

LED1

Main, inspection (red)

LED2

Main, normal (green)

LED3

Main, service (green)

LED4~6

7-segment LED (function display)

LED7~9

7-segment LED (data display)

LED10

Sub, normal (green)

LED 11

Sub, inspection (red)

Symbol

Name

LED 12

Sub, service (green)

OLS1-2

Oil level sensor

PSH

High pressure sensor

PSL

Low pressure sensor

PSM

Middle pressure sensor

PWB1~3,5~7

Printed wiring board

R1-1,2,3

Inrush suppression resistance

R3-1,2

Discharge resistance

R5

Drop resistance

R6

Termination resistance

R7

Filter resistance

SVHG1

Solenoid valve for hot gas bypass

SV-INJ1

Solenoid valve for gas injection

SV-OIL1-2

Solenoid valve for oil return

SW1

Compressor low pressure control setting (10s)

SW2

Compressor low pressure control setting (1s)

SW3-1~3

Spare

SW3-4

Protection start II cancel

SW3-5

Gas cooler fan control

SW3-6

Spare

SW3-7

Compressor total operation time reset

SW3-8

Spare

SW4-1~4

Model selection

SW4-5~8

Spare

SW5-1~3

For target middle pressure adjustment

SW5-4,5

Spare

SW5-6~8

Pressure check operation mode

Symbol

Name

SW6-1~3

Spare

SW6-4

Presence of subcooling suppression control

SW6-5

Oil level error/oPE display switching

SW6-6

Presence of regular inspection and

maintenance contract

SW6-7

Oil level error

Sw6-8

Spare

SW7

Data erase/write

SW8

7-segment display (1s)

SW9

7-seqment display (10s)

TB1,2

Terminal block

Tho-A

Outdoor air temp. sensor

Tho-C1

Under dome temp. sensor

Tho-D1

Discharge pipe temp. sensor

Tho-G1

Gas cooler temp. sensor 1 (inlet)

Tho-G2

Gas cooler temp. sensor 2 (outlet)

Tho-INJ1

Gas injection inlet temp. sensor 1

Tho-M

Middle pressure receiver inlet temp. sensor

Tho-P1

Power transistor temp. sensor

Tho-R

Liquid feed pipe temp. sensor

Tho-SC

Subcooling coil temp. sensor

Tho-S

Suction pipe temp. sensor

ON-OFF SW

Operation switch

52X1-1,2

Magnetic contactor for CM

63H1-1

High pressure switch

Notes

1. This drawing shows the electrical circuit of CO2 condensing unit.

2. Dotted line (----- ) shows the wiring on site.

Long dashed double-short dashed line (----- ) shows installation on site.

3. Separate signal line from power line.

4. CNG1,CNG2,CNS1,CNS2 and CNS3 are no voltage contact inputs.

If they will be used, use the attached harness for level input.

5. Output of CNH,CNY,CNZ1 and CNZ2 is 12V. Maximum current is less than 20mA (+ side (1 PIN side) is common) .

If they will be used, use the attached harness and be sure to connect to unit relay (Coil resistance of 7502 or more

provided on site).

U (red)

W (Blue)

Enlarged drawing of

compress terminals

V (White)

Ex

ter

nal output 2

Ex

ter

nal output 1

Er

ror output

Oper

ation output

Oper

ation in

tput

G

as c

ooler fan sno

w

con

tr

ol input

Multistage demand input

C

ompulsor

y oil

retun c

on

tr

ol input

ON - OFF SW

ASSLY CO2 MODULE CONTROLLER

Super Link

Adapter PCB

PWB6

User interface

MMILDS

12VDC

Power

Module controller

Circuit breaker

for cabling

Earth leakage

breaker

Power source

Inverter PCB

Compressor terminal

See enlarged view

Control PCB

PWB1

Noise filter PCB

Power PCB PWB5

Remote PCB PWB7

Ready connector

30

AB408540130380en-000102

© Danfoss | Climate Solutions | 2023.02

Application Guidelines