TECHNICAL DATA

ELECTRICAL

NOMINAL START CURRENT

± 11 mA (single coil)

± 16 mA (using one of the dual coils)

± 8 mA (using the dual coils in series)

± 16 mA (using the dual coils in parallel)

± 6.25 mA (low current models)

NOMINAL FULL STROKE CURRENT

(See Current vs. Swashplate Angle and Wiring Schemes)

85 ± 12 mA (single coil)

125 ± 18 mA (using one of the dual coils)

62 ± 9 mA (using the dual coils in series)

125 ± 18 mA (using the dual coils in parallel)

18 ± 1.5 mA (low current models)

Current tolerances include ± 5 mA for single coil and ±

pump series’. For sizing drive sources, use 100 mA in compu-

tations for single coil EDC’s.

COIL RESISTANCE @ 24° C (76° F)

23 ohms (single coil)

19.5 ohms (A, B Terminals),

15.5 ohms (C, D Terminals) (dual coil)

650 ohms (low current models)

COIL RESISTANCE @ 104° C (220° F)

29 ohms (single coil)

24.7 ohms (A, B Terminals),

19.7 ohms (C, D Terminals) (dual coil)

800 ohms (low current models)

COIL INDUCTANCE

.14 henries (single coil)

.062 henries (A, B Terminals),

.047 henries (C, D Terminals) (dual coil)

MAXIMUM CONTINUOUS VOLTAGE @ 93.3° C(200° F)

•

7.5 Vdc for single coil models with the exceptionof those

low current models

•

14 Vdc for dual coil models in series

•

7.5 Vdc for dual coil models when only one coil or both coils

in parallel are used

•

24 Vdc for low curent models.

The EDC is designed to be controlled from a dc current source or

voltage source. Pulse width modulation (PWM) is not required.

But if a PWM signal is used, avoid a carrier frequency <200 Hz.

Do not use a pulse current of more than 120% of that required

for full output.

HYDRAULIC

OIL VISCOSITY

40 - 6000 SSU

OIL TEMPERATURE

- 40° C (- 40° F) minimum

+ 104° C (+220° F) maximum continuous

+ 116° C (+240° F) maximum intermittent

AMBIENT OPERATING TEMPERATURE

- 40° to 93° C (- 40° to 200° F)

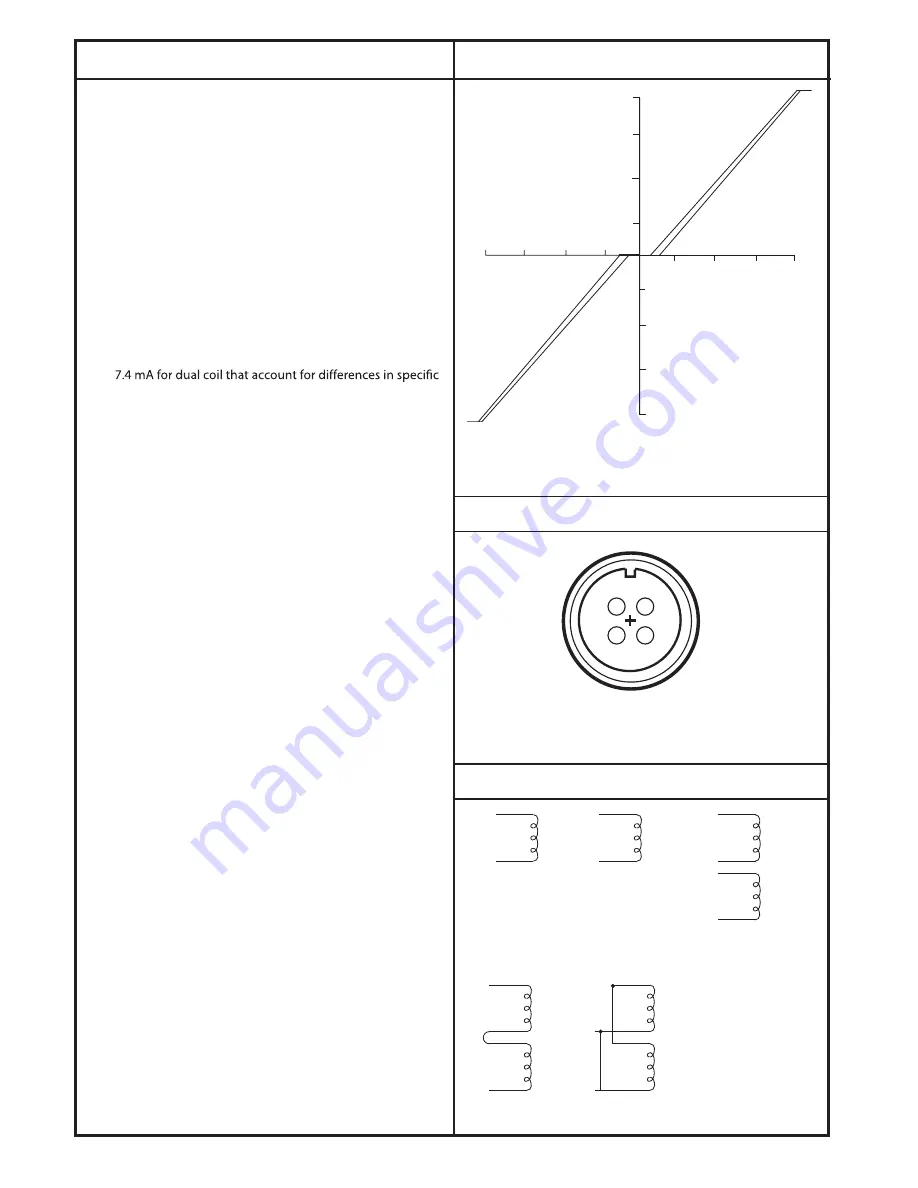

SINGLE COIL 85 MA

WITH 2.0 VDC

INPUT AT FULL STROKE.

+A

B

USING ONE OF THE TWO DUAL COILS,

125 MA WITH 1.9 VDC (C, D COIL) OR

2.4 VDC (A, B COIL)

INPUT AT FULL STROKE.

+A

B

+C

D

DUAL COILS IN SERIES,

62 MA WITH 2.2 VDC

INPUT AT FULL STROKE.

+

B

C

D

A

DUAL COILS IN PARALLEL,

125 MA WITH 1.1 VDC

INPUT AT FULL STROKE.

+

B

C

D

A

+A

B

SINGLE COIL 20 MA

WITH 15 VDC

INPUT AT FULL STROKE.

(LOW CURRENT MODEL)

CURRENT VS. SWASHPLATE ANGLE

Current Vs. Swashplate Angle for the MCV104A.

Single-Coil Load Pressure is 3000 PSI and Current Input is 0.01

Hz.

1141

15∞

10∞

5∞

5∞

10∞

15∞

80 mA

60 mA

40 mA

20 mA

20 mA

40 mA

60 mA

80 mA

18∞

18∞

SWASHPLATE ANGLE (DEGREES)

INPUT CURRENT (MA)

1300

WIRING SCHEMES

CONNECTION DIAGRAM

Pin Orientation of 4-pin, 90° MS Mating Connector. Part

No. MS3108E-14S-2S (Sauer-Danfoss Kit No. K08106).

1276

D

C

A

B

700

Ω

24

Ω

19.5

Ω

15.5

Ω

35 Ω

(TOTAL

RESISTANCE)

9 Ω

(TOTAL

RESISTANCE)

© Danfoss, 2013

K07116

•

Rev A

B

• September 2013

5