Danfoss ET1000 Crimp machine operator’s manual

AQ418954799548en-000101

© Danfoss ET1000 Crimp machine operator’s manual | 2022.06. | 5

Maintenance

Maintenance

Intervals

Machine

maintenance

procedures

Collet Assembly & Die

Ring Adapter Plate

Lubrication:

Every 30 crimps =

Re-lubricate sliding

surfaces of dies

Every 250 crimps =

Remove old grease

and re-lubricate

Base Die Ring & Die Ring

Adapter Plate

Maintenance:

Every 250 crimps = Remove old

grease and re-lubricate

Every 1,000 crimps =

Remove old grease,

inspect for wear or damage and

relubricate if okay.

1.

Sliding surfaces must be kept

free of dirt and other abrasive

materials.

2.

All exposed black metal surfac-

es should be coated occasion-

ally with a light film of oil to

prevent corrosion.

3.

Some fitting/hose combina-

tions require full pump reser-

voir capacity to complete the

crimp cycle. The oil level in the

fluid reservoir of the hydraulic

pump should be checked peri-

odically and refilled as required

with the pump manufacturer’s

hydraulic oil as needed.

NOTE:

Completely retract

the cylinder when checking the

oil level.

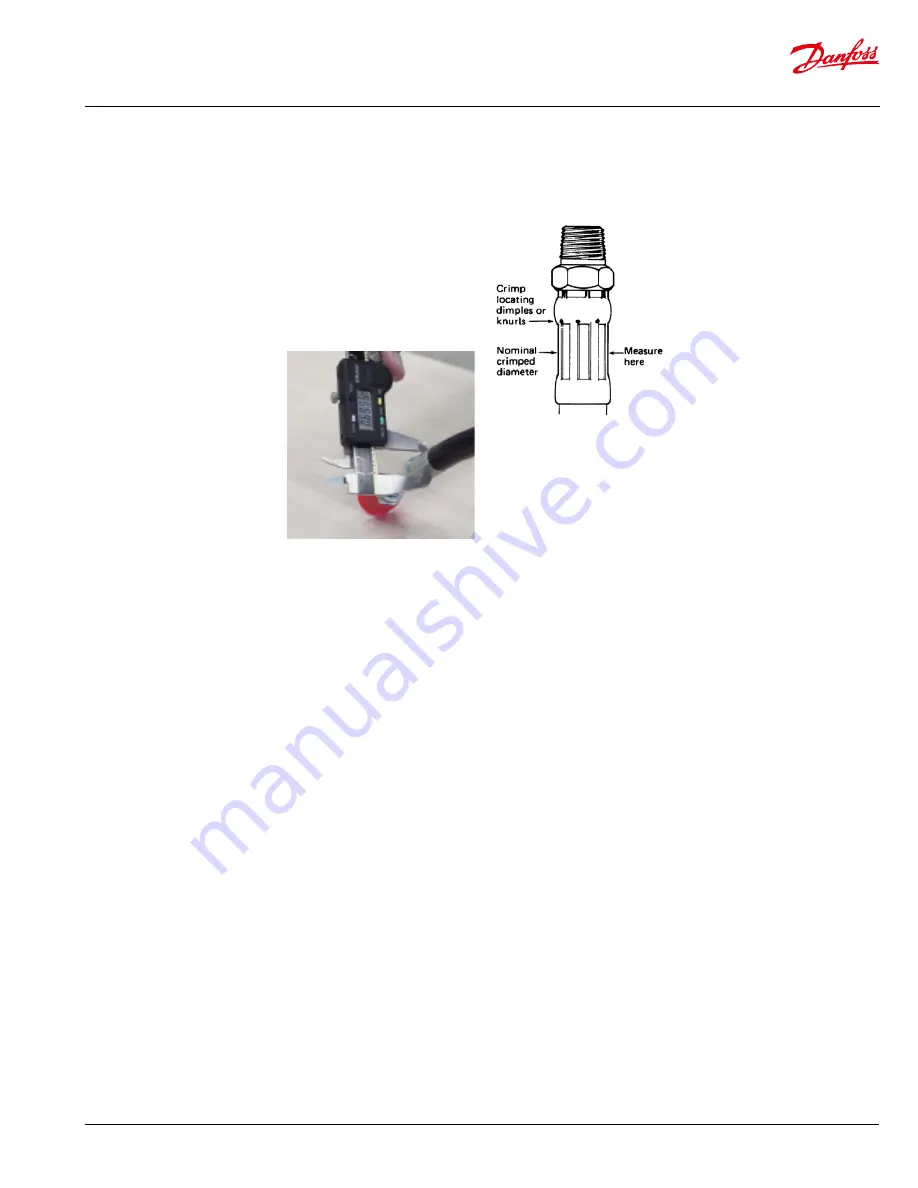

Nominal crimp diameter

Crimping procedures (cont.)

Measuring crimp diameters

should be a part of the

normal hose assembly

procedure. To ensure a

proper crimp diameter,

follow these steps:

1.

Measure the diameter in

the middle of the crimped

portion of the hose end. Place

the caliper in a position to al-

low for a measurement across

the pressed (flat) portion of

the crimp.

2.

Repeat step 1 for each of the

remaining sides for a total of

four measurements.

3.

Average the four measure-

ments and compare this

average to the target crimp

diameter shown in the Power

Source crimp spec tool and

ensure it falls within tolerance.