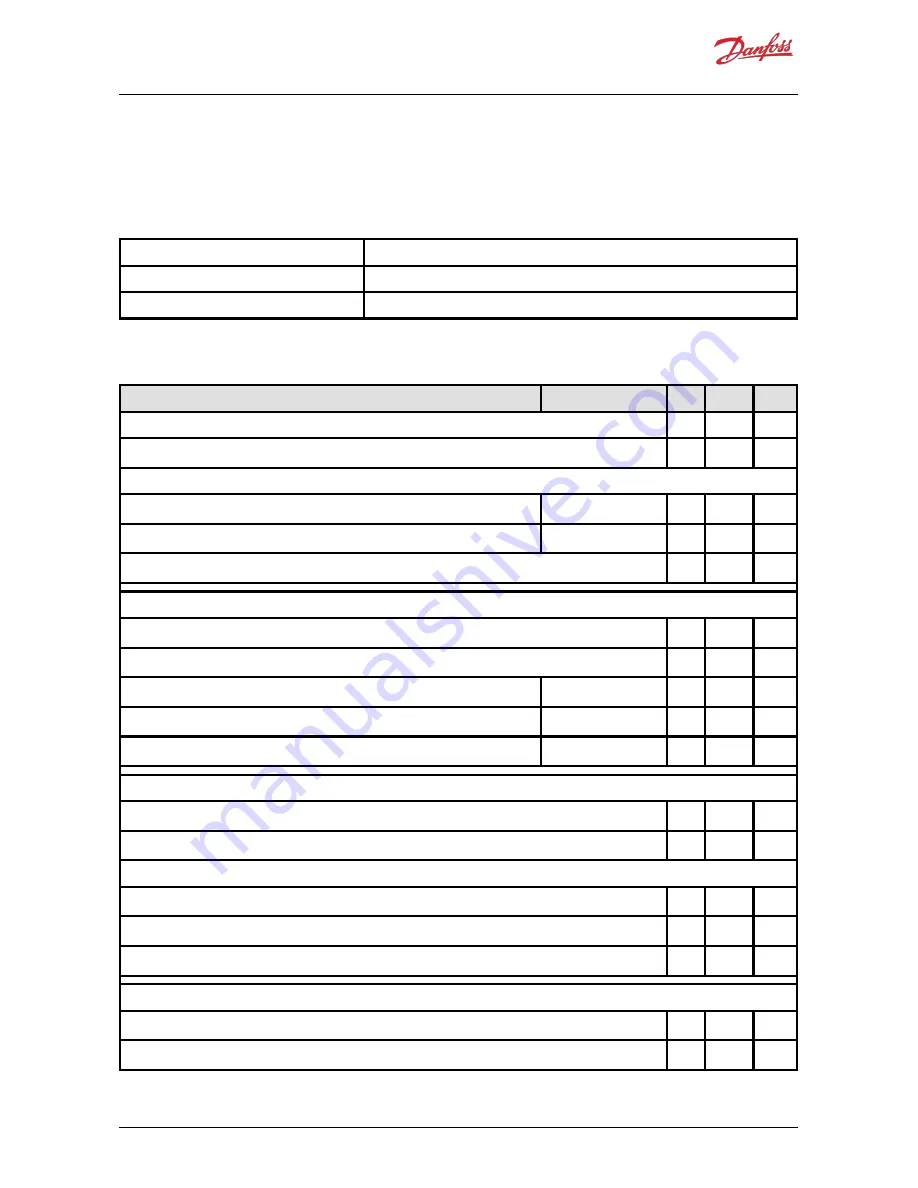

Electric Machine Yearly Maintenance Checklist

Date:

Table 20. Machine and customer information

Customer:

Machine type (from the rating plate):

Customer reference:

Machine serial number:

Service reference:

Date installed:

N.A = Procedure not applicable PASS = Procedure passed FAIL = Procedure failed

Table 21. Yearly maintenance checklist

Acceptance

N.A

PASS

FAIL

General construction

Noise or vibration during operation in general

☐

☐

☐

Mounting bolt tightness

D-end attachment bolt tightening torque

40 Nm

☐

☐

☐

N-end attachment bolt tightening torque

30 Nm

☐

☐

☐

Cleanliness of the enclosure and connected parts

☐

☐

☐

Electrical system

Weariness of the cables

☐

☐

☐

Electrical connections in general

☐

☐

☐

Cable gland tightening torque (to the box)

15 Nm

☐

☐

☐

Cable lug tightening torque (to the busbar)

13 Nm

☐

☐

☐

Connection box cover bolts tightening torque

4 Nm

☐

☐

☐

Cooling system

Coolant ow direction changed and connection checked

☐

☐

☐

Coolant quality as speci ed

☐

☐

☐

Used coolant:

Functioning of the cooling system in general

☐

☐

☐

Tightness of the tubing and connections (no leakages)

☐

☐

☐

Cleanliness of the ventilation plug

☐

☐

☐

Grounding

Power cable shield connection resistances to ground (machine enclosure) checked

☐

☐

☐

Low voltage cable shield grounding resistances checked

☐

☐

☐

Do not try to tighten bolts or screws that are not discussed in the product manual and that are not

needed for the normal installation procedures. Sealing of the screws may break.

EM-PMI375

13. Storage, installation and maintenance checklists

72 |

©

Danfoss | Produced By: Danfoss Power Solutions | January 2019

| BC265856307805en-000105

Summary of Contents for EM-PMI375-T200

Page 1: ...User Guide Motor Generator EM PMI375 danfoss com ...

Page 77: ......