Document Number: P-SS-004-09 Rev 5

Old Numbers (AS6007H, A-SS-004-20208)

Revised 11/20/2003

www.DanaherMotion.com

Page

2

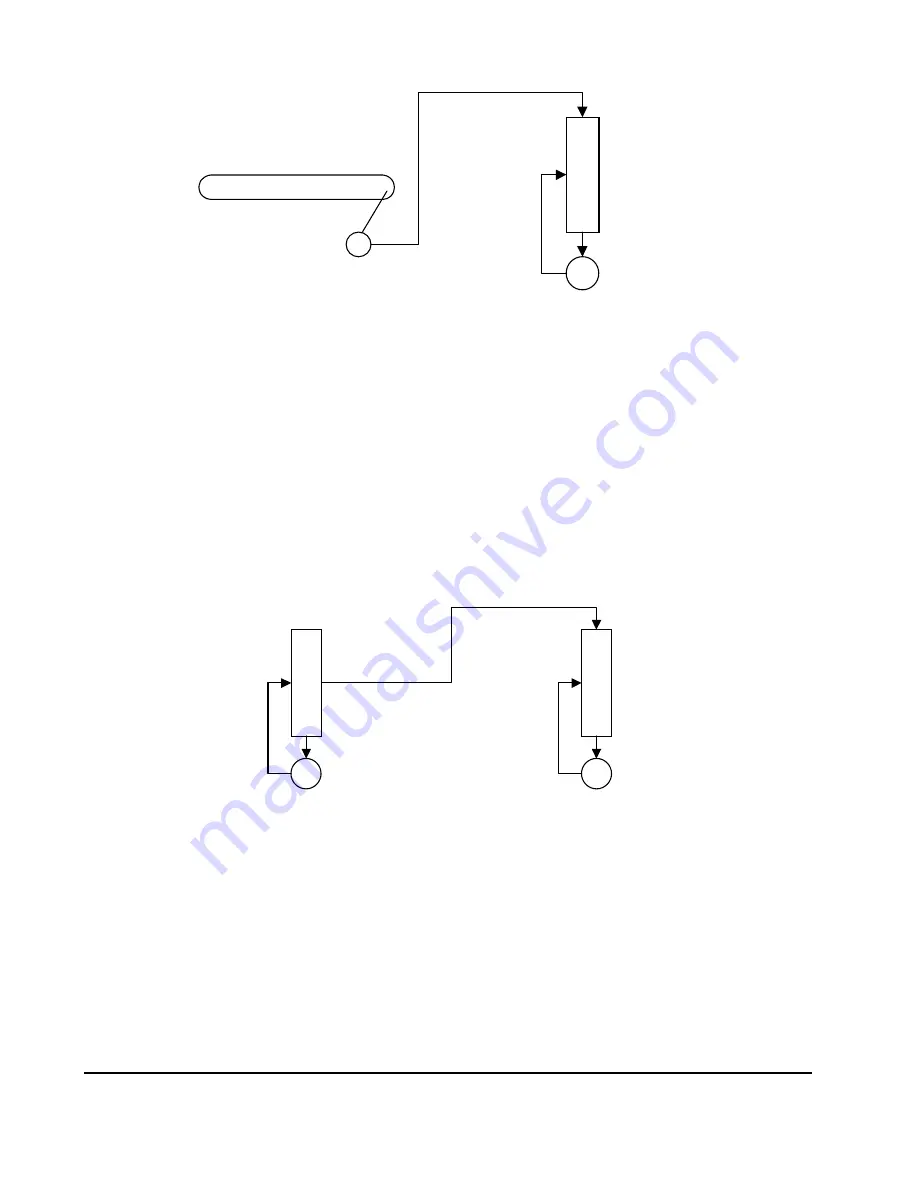

Conveyor

Encoder

SE

R

V

O

ST

A

R

S

60

0

Encoder input

Resolver/

sine encoder

feedback

Electronically-

geared

drive

Electronically-

geared

motor

Figure 1: Following a Non-driven Encoder

Following a Servomotor

Some gearing applications need one servomotor to follow another. Here, the encoder from the first

(master) motor becomes the gearing input to the second (slave) motor. In this case, the master

encoder must connect as both the feedback for the master drive and input for the slave drive.

For cases where the feedback device of the master servomotor is something other than a physical

encoder, the SERVO

STAR

S600 provides encoder emulation. For example, neither a sine encoder

nor a resolver directly produce signals compatible with encoders. The SERVO

STAR

S600 encoder

emulation circuit produces output signals equivalent to an encoder from any feedback device that is

used as the main feedback device. This allows any SERVO

STAR

S600 to serve as the master for

any other electronically-geared SERVO

STAR

S600.

SE

RV

O

ST

A

R

S6

00

Encoder input

Resolver/

sine encoder

feedback

Electronically-

geared

drive

Electronically-

geared

motor

SE

RV

O

ST

A

R

S6

00

Resolver/

sine encoder

feedback

Master

drive

Master

motor

Encoder

emulation

output

Figure 2: Following a Servo-driven Encoder

Following a Multi-Pulse Generator (MPG)

Some applications require a motor to follow the input from an operator via a multi-purpose

generator (MPG), such as an encoder handwheel. In many cases, a traditional contact-based

potentiometer is used to take input from the operator. However, such a device is not appropriate for

some environments because the contact surface wears over time and becomes unreliable. By using

electronic gearing, an optical encoder is used to replace a contact potentiometer. The

SERVO

STAR

S600 accepts the input from an encoder as either a velocity or position command.