Display Troubleshooting

15

9 Display Troubleshooting

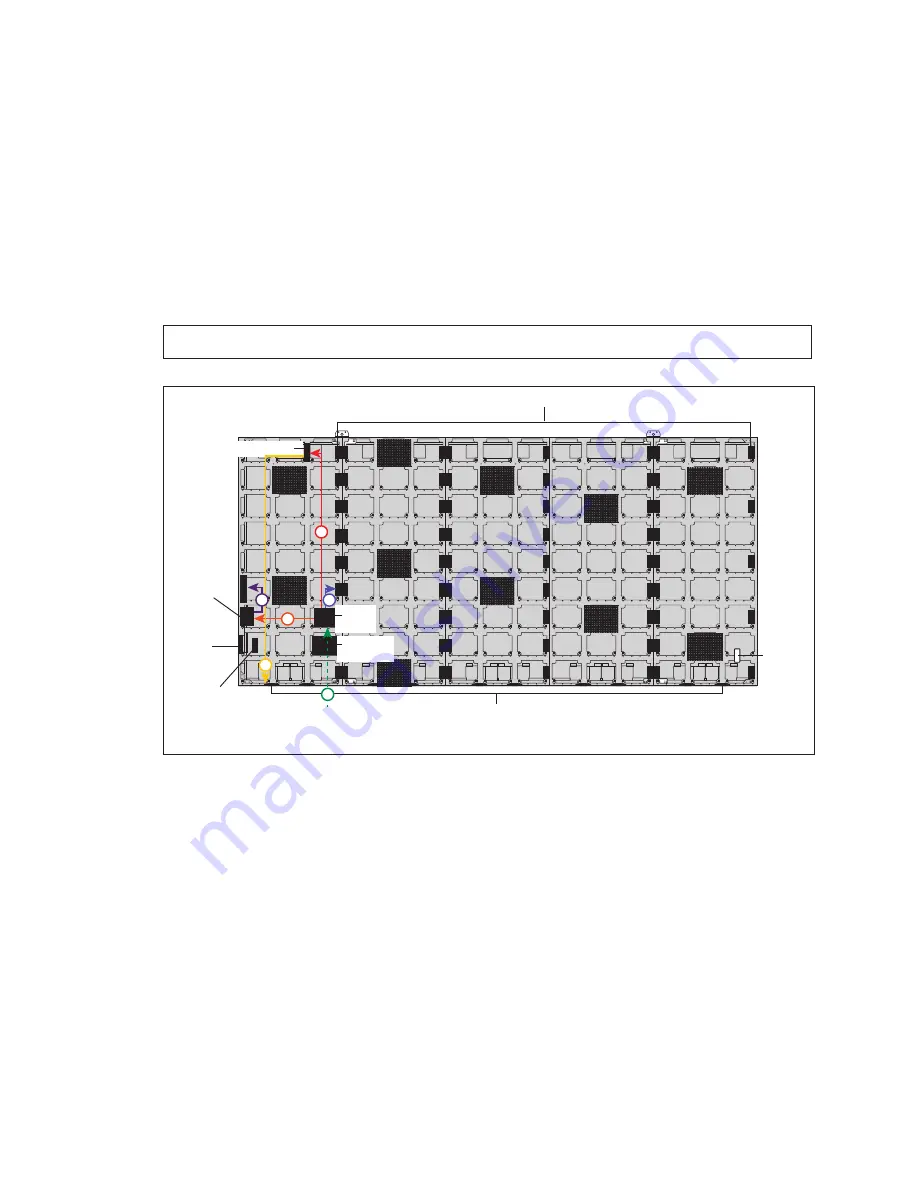

This section provides basic display information such as power and signal routing as well as

basic troubleshooting tips for common problems. For issues not addressed in this manual,

please contact Daktronics Technical Support.

Power and Signal Routing

Understanding power and signal flow through the display can help a technician

troubleshoot an issue.

Power Routing

shows an example of how power is routed through the display.

1.

AC Power enters the display through the power entrance box on the back of the

display and travels to the Power Termination Panel.

2.

Power is distributed to Module Power Supplies (2a), Player Power Supply (2b),

Thermostat (2c), and Fans (2d).

3.

DC Power is also supplied to the PLR (4) from the Player Power Supply.

P

L

R

PLR Power

Supply

Quick

Connect

Input

Term

Panel

Power

Entrance

Quick

Connect

Output

Fans

Light

Sensor

Thermostat

Power Supplies (PS)

PS

PS

PS

PS

PS

PS

PS

PS

PS

PS

PS

PS

PS

PS

PS

PS PS

PS

PS

PS

PS

PS

PS

PS

PS

PS

PS

PS

PS

PS

PS

PS

PS

PS

PS

PS

PS

PS

PS

PS

PS

PS

PS

PS

PS

PS

PS

PS

PS

PS

PS

PS

PS

PS

PS

PS

PS

PS

PS

PS

PS

PS

PS

PS

1

2a

2b

2c

2d

3

Figure 11:

Power Routing

Note:

Power routing may vary depending on display size.

Summary of Contents for VANGUARD VC6

Page 4: ......