Dakota Ultrasonics

14

AGC:

The

PR-8V

is equipped with an automatic gain control when operating in

echo-echo mode only. This is much like turning the volume up or down on a stereo

receiver. However, the

PR-8V

will automatically control how much the volume is

turned up or down. Alternatively, the AGC can be manually controlled using the

same procedures as GAIN described above. Refer to page 51 for further info.

Measure Mode:

Used to select the measurement mode for different application

requirements. The modes are P-E (pulse-echo) and E-E(echo -echo). Refer to page

22 for further info.

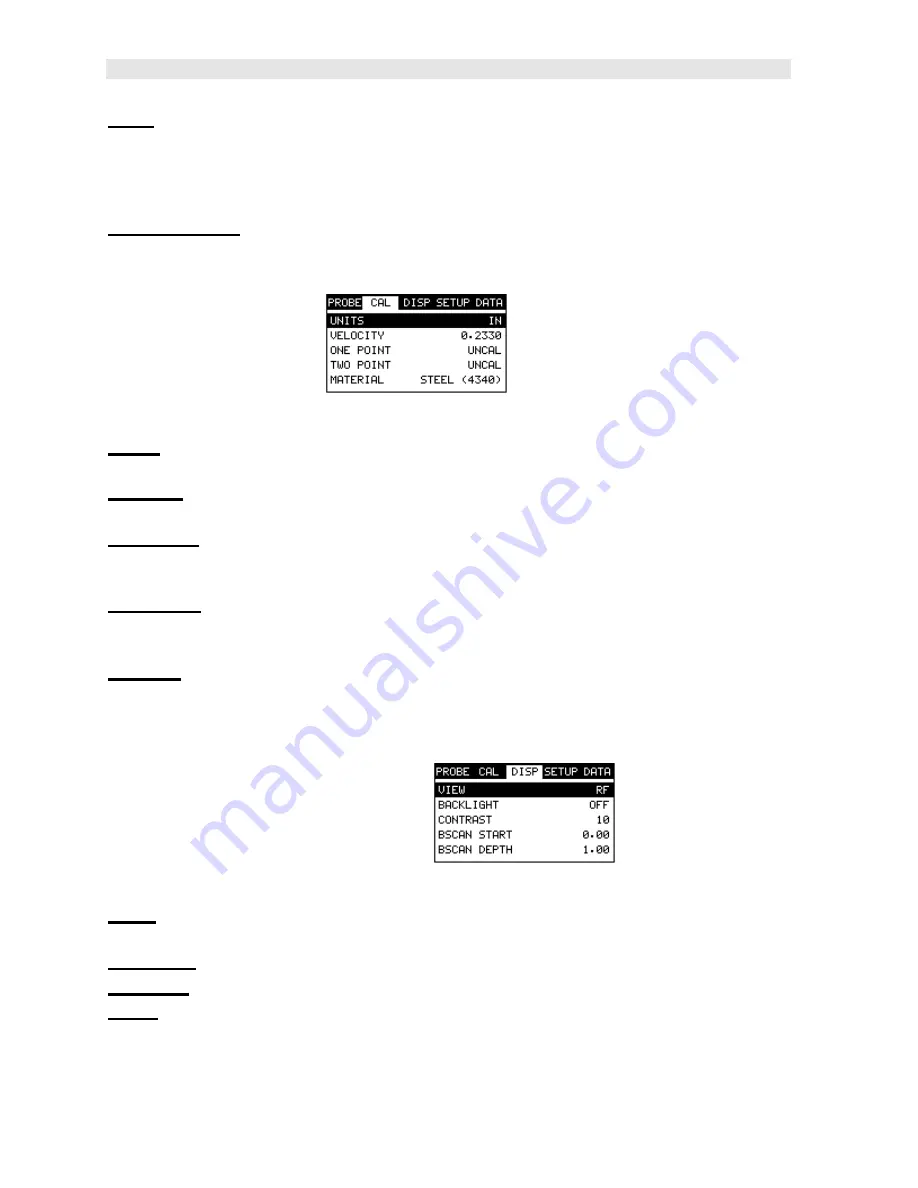

3.3 CAL – Menu

Units:

Toggle between English or Metric units. The readout will change from inches

to millimeters.

Velocity:

Function to calibrate the PR-8V by setting the velocity to a known material

velocity. Refer to page 34 for further info.

One Point:

Performs a single point calibration. This option allows the user to

automatically calculate the velocity by entering a known sample thickness. Refer to

page 36 for further info.

Two Point:

Performs a two -point calibration. This option allows the user to

automatically calculate the velocity by entering a second known sample thickness.

Refer to page 37 for further info.

Material:

Select the material velocity from a chart of basic material types, when a

known sample thickness, or material velocity cannot be obtained. Refer to page 40

for further info.

3.4 DISP (display) – Menu

View:

Selectable RF wave, RECT (rectified) wave, BSCAN (cross section), and

DIGITS (large digits) views. Refer to page 42 for further info.

Backlight:

Selectable OFF, ON, AUTO, or INVERT backlight option.

Contrast:

Adjustable display contrast for variable light conditions.

B-ST:

Provides the user the ability to change the start position o f the B-SCAN view.

Refer to page 49 for further info.