IM 1044-2

Centrifugal Chillers

51

Then the system is once again evacuated to approximately 29 inches of mercury. This is repeated three times. The

first pulldown will remove about 90% of the noncondensables, the second about 90% of that remaining from the

first pulldown and, after the third, only 1/10-1% noncondensables will remain.

Charging the System

WSC and WDC water chillers are leak tested at the factory and shipped with the correct charge of refrigerant as

indicated on the unit nameplate. In the event the refrigerant charge was lost due to shipping damage, the system

should be charged as follows after first repairing the leaks and evacuating the system.

1.

Connect the refrigerant drum to the gauge port on the liquid line shutoff valve and purge the charging line

between the refrigerant cylinder and the valve. Then open the valve to the mid-position.

2.

Turn on both the cooling tower water pump and chilled water pump and allow water to circulate through the

condenser and the chiller. (It will be necessary to manually close the condenser pump starter.)

3.

If the system is under a vacuum, stand the refrigerant drum with the connection up, and open the drum and

break the vacuum with refrigerant gas to a saturated pressure above freezing.

4.

With a system gas pressure higher than the equivalent of a freezing temperature, invert the charging cylinder

and elevate the drum above the condenser. With the drum in this position, valves open, water pumps

operating, liquid refrigerant will flow into the condenser. Approximately 75% of the total requirement

estimated for the unit can be charged in this manner.

5.

After 75% of the required charge has entered the condenser, reconnect the refrigerant drum and charging

line to the service valve on the bottom of the evaporator. Again purge the connecting line, stand the drum

with the connection up, and place the service valve in the open position.

IMPORTANT

: At this point, the charging procedure should be interrupted and prestart checks made

before attempting to complete refrigerant charge. The compressor must not be started at this time.

(Preliminary check must first be completed.)

NOTE

: It is of utmost importance that all local, national, and international regulations concerning the

handling and emission of refrigerants are observed.

Oil Analysis

Interpreting Oil Analysis Data

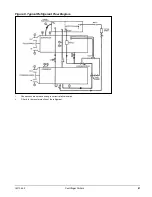

Oil wear metals analysis has long been recognized as a useful tool for indicating the internal condition of

rotating machinery and continues to be a preferred method for

Daikin

centrifugal chillers.

Daikin

Service or a

number of laboratories specializing in oil testing can do the test. To accurately estimate the internal condition it

is essential to properly interpret the oil wear test results.

Numerous test results from various testing laboratories have recommended action that has prompted unnecessary

concern by customers. Polyolester oils are excellent solvents and can readily dissolve trace elements and

contaminants. Most of these elements and contaminates eventually end up in the oil. Also, the polyolester oils

used in R-134a chillers are more hygroscopic than mineral oils and can contain much more water in solution. For

this reason, it is imperative that extra care be used when handling polyolester oils to minimize their exposure to

ambient air. Extra care must also be used when sampling to ensure that sample containers are clean, moisture-free

leak proof and non-permeable.

Daikin

has done extensive testing in conjunction with refrigerant and lubricating oil manufacturers and has

established guidelines to determine action levels and the type of action required. Table 1 indicates these

parameters.

In general

Daikin

does not recommend changing lubricating oils and filters on a periodic basis. The need to

change lubricating oil and filters should be based on a careful consideration of oil analysis, vibration analysis

and knowledge of the operating history of the equipment. A single oil sample is not sufficient to estimate the

condition of the chiller. Oil analysis is only useful if employed to establish wear trends over time. Changing