4 Installation

Installation manual

6

RZQG7 RZQG71~12 RZQG140L7Y1L

Split system air conditioners

4P473073-1A – 2019.04

5

If the outdoor unit is installed above the indoor unit, cover the

stop valves (f, see above) with sealing material to prevent

condensed water on the stop valves from moving to the indoor

unit.

NOTICE

Any exposed piping might cause condensation.

6

Reattach the service cover and the piping intake plate.

7

Seal all gaps (example: a) to prevent snow and small animals

from entering the system.

a

WARNING

Provide adequate measures to prevent that the unit can be

used as a shelter by small animals. Small animals that

make contact with electrical parts can cause malfunctions,

smoke or fire.

NOTICE

Make sure to open the stop valves after installing the

refrigerant piping and performing vacuum drying. Running

the system with the stop valves closed may break the

compressor.

4.2.2

To determine if oil traps are required

If oil flows back into the outdoor unit's compressor, this might cause

liquid compression or deterioration of oil return. Oil traps in the rising

gas piping can prevent this.

If

Then

The indoor unit is installed

higher than the outdoor

unit

Install an oil trap every 10 m (height

difference).

a

b

10 m

a

Rising gas piping with oil trap

b

Liquid piping

The outdoor unit is

installed higher than the

indoor unit

Oil traps are NOT required.

4.3

Checking the refrigerant piping

4.3.1

Checking refrigerant piping: Setup

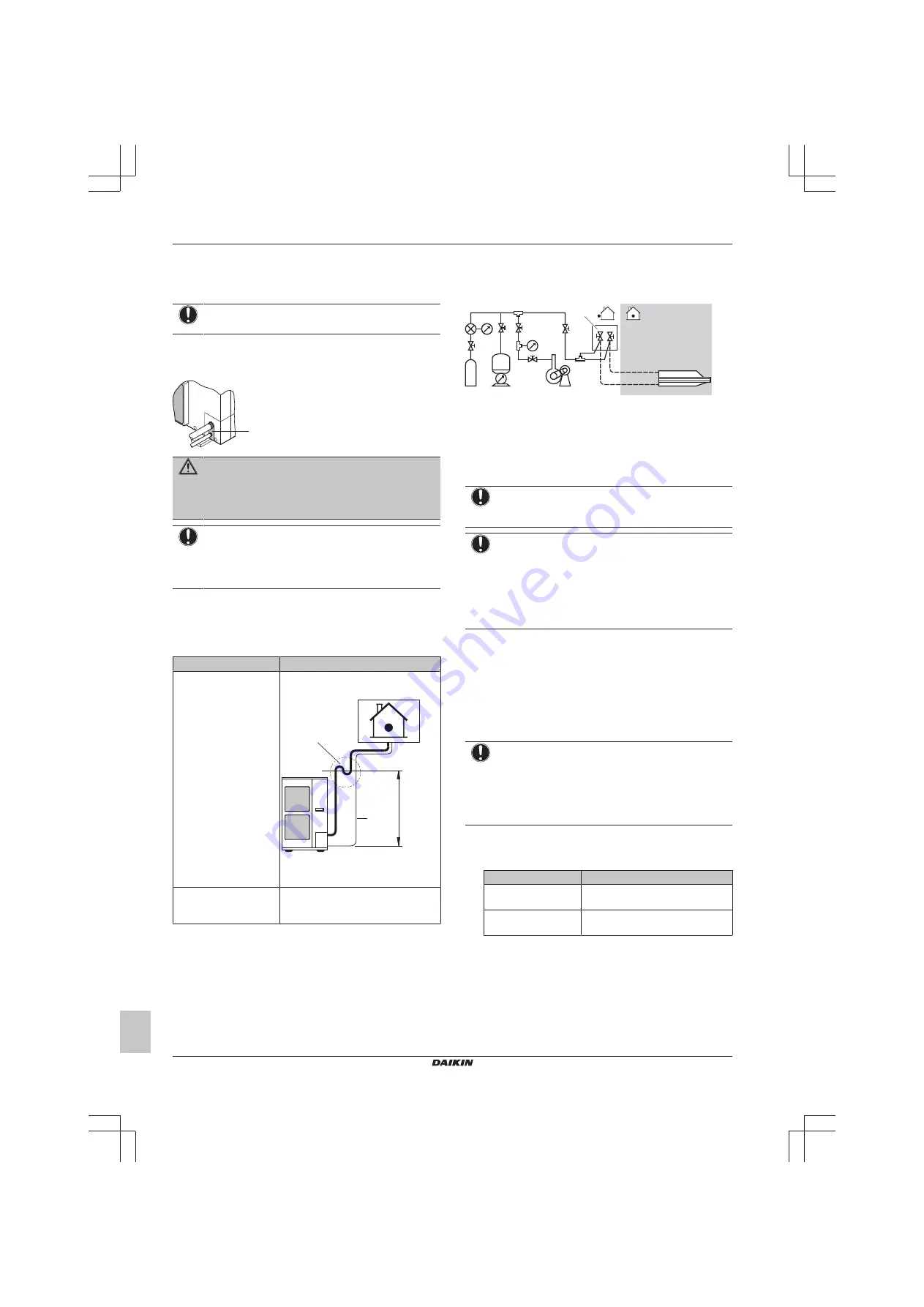

a

c

f

b

d

e

R410A

a

Pressure gauge

b

Nitrogen

c

Refrigerant

d

Weighing machine

e

Vacuum pump

f

Stop valve

4.3.2

To check for leaks

NOTICE

Do NOT exceed the unit's maximum working pressure (see

"PS High" on the unit name plate).

NOTICE

Make sure to use a recommended bubble test solution

from your wholesaler. Do not use soap water, which may

cause cracking of flare nuts (soap water may contain salt,

which absorbs moisture that will freeze when the piping

gets cold), and/or lead to corrosion of flared joints (soap

water may contain ammonia which causes a corrosive

effect between the brass flare nut and the copper flare).

1

Charge the system with nitrogen gas up to a gauge pressure of

at least 200 kPa (2 bar). It is recommended to pressurize to

3000 kPa (30 bar) in order to detect small leaks.

2

Check for leaks by applying the bubble test solution to all

connections.

3

Discharge all nitrogen gas.

4.3.3

To perform vacuum drying

NOTICE

▪ Connect the vacuum pump to

both

the service port of

the gas stop valve and the service port of the liquid

stop valve to increase efficiency.

▪ Make sure that the gas stop valve and liquid stop valve

are firmly closed before performing the leak test or

vacuum drying.

1

Vacuum the system until the pressure on the manifold indicates

−0.1 MPa (−1 bar).

2

Leave as is for 4-5 minutes and check the pressure:

If the pressure…

Then…

Does not change

There is no moisture in the system.

This procedure is finished.

Increases

There is moisture in the system. Go

to the next step.

3

Vacuum the system for at least 2 hours to a manifold pressure

of −0.1 MPa (−1 bar).

4

After turning the pump OFF, check the pressure for at least

1 hour.

5

If you do NOT reach the target vacuum or CANNOT maintain

the vacuum for 1 hour, do the following:

▪ Check for leaks again.

▪ Perform vacuum drying again.

Summary of Contents for RZQG71L9V1L

Page 14: ......

Page 15: ......

Page 16: ...4P473073 1A 2019 04 Copyright 2017 Daikin 4P473073 1 A 0000000...