D-EIMWC00908-16EN - 14/52

Water treatment

Before putting the machine into operation, clean the water circuit. Dirt, scale, corrosion residue and other foreign material

can accumulate inside the heat exchanger and reduce its heat exchanging capacity. Pressure drop can increase as well,

thus reducing water flow. Proper water treatment therefore reduces the risk of corrosion, erosion, scaling, etc. The most

appropriate water treatment must be determined locally, according to the type of system and local characteristics of the

process water.

The manufacturer is not responsible for damage to or malfunctioning of equipment caused by failure to treat water or by

improperly treated water.

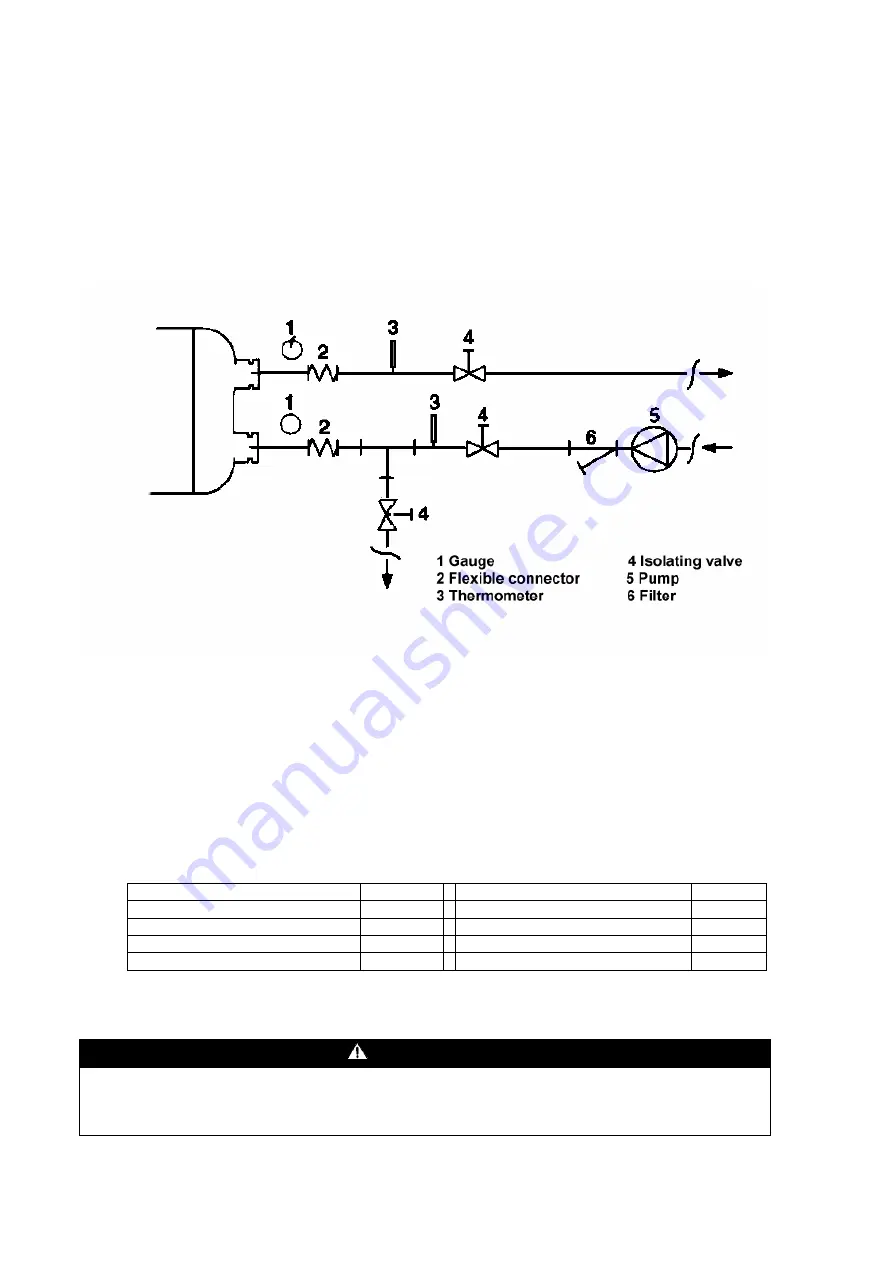

Figure 3 - Water piping connection for evaporator and condenser

Legend translation

Gauge

Gauge

Flexible connector

Flexible connector

Flow switch

Flow switch

Thermometer

Thermometer

Isolating valve

Isolating valve

Pump

Pump

Filter

Filter

Table 1 - Acceptable water quality limits

pH (25°C)

6,8

8,0

Total Hardness (mg CaCO

3

/ l)

200

Electrical conductivity

S/cm (25°C)

800

Iron (mg Fe / l)

1.0

Chloride ion (mg Cl

-

/ l)

200

Sulphide ion (mg S

2 -

/ l)

None

Sulphate ion (mg SO

2

4

-

/ l)

200

Ammonium ion (mg NH

4

+

/ l)

1.0

Alkalinity (mg CaCO

3

/ l)

100

Silica (mg SiO

2

/ l)

50

Evaporator exchangers anti-freeze protection

ATTENTION

Neither the evaporator nor the condenser is self-draining and it has no heater installed. Both heat exchangers

must be protected against freezing

Summary of Contents for EWWD320

Page 16: ...D EIMWC00908 16EN 16 52 Figure 4 Evaporator pressure drop...

Page 17: ...D EIMWC00908 16EN 17 52...

Page 18: ...D EIMWC00908 16EN 18 52 Figure 5 Condenser pressure drop...

Page 34: ...D EIMWC00908 16EN 34 52 Figure 12 Compressor overview...

Page 50: ...D EIMWC00908 16EN 50 52...

Page 51: ...D EIMWC00908 16EN 51 52...