Installation manual

21

E(D/B)(H/L)Q011~016BB

Unit for air to water heat pump system

4PW67904-1 – 01.2011

9.2.

Internal wiring - Parts table

Refer to the internal wiring diagram supplied with the unit (on the

inside of the switch box cover). The abbreviations used are listed

below.

Door 1 compressor compartment and electrical parts

A1P ................. Main PCB

A2P ................. Inverter PCB

A3P ................. Noise filter PCB

A4P ................. PCB (only for V3 models)

BS1~BS4......... Push button switch

C1~C4 ............. Capacitor

DS1 ................. DIP switch

E1H ................. Bottom plate heater

E1HC............... Crankcase heater

F1U,F2U.......... Fuse (31.5 A/250 V) (only for W1 models)

F1U,F3U,F4U .. Fuse (T 6.3 A/250 V) (only for V3 models)

F3U~F6U......... Fuse (T 6.3 A/250 V) (only for W1 models)

F6U ................. Fuse (T 5.0 A/250 V) (only for V3 models)

F7U ................. Fuse (T 5.0 A/250 V) (only for W1models)

F7U,F8U.......... Fuse (F 1.0 A/250 V) (only for V3 models)

F8U,F9U.......... Fuse (F 1.0 A/250 V) (only for W1 models)

H1P~H7P ........ Orange LED service monitor

(A1P only for W1 models, A2P only for V3 models)

H2P: prepare, test = flickering

H2P: malfunction detection = light up

HAP (A1P)....... Green LED service monitor

HAP (A2P)....... Green LED service monitor (only for W1 models)

K1M,K2M ........ Magnetic contactor (only for W1 models)

K1R ................. Magnetic relay (Y1S) (only for V3 models)

K1R (A1P) ....... Magnetic relay (Y1S) (only for W1 models)

K1R (A2P) ....... Magnetic relay (only forW1 models)

K2R (A1P) ....... Magnetic relay (Y2S) (only for W1 models)

K3R (A1P) ....... Magnetic relay (E1HC) (only for W1 models)

K4R ................. Magnetic relay (E1HC) (only for V3 models)

K10R,K11R ..... Magnetic relay (only for V3 models)

L1R.................. Reactor (only for V3 models)

L1R~L3R ......... Reactor (only for W1 models)

L4R.................. Reactor for (fan motor) (only for W1 models)

M1C................. Motor (compressor)

M1F ................. Motor (upper fan)

M2F ................. Motor (lower fan)

PS ................... Switching power supply

Q1DI................ Earth leakage circuit breaker

R1,R2 .............. Resistor (only for V3 models)

R1~R4 ............. Resistor (only for W1 models)

R1T ................. Thermistor (air)

R2T ................. Thermistor (discharge)

R3T ................. Thermistor (suction)

R4T ................. Thermistor (heat exchanger)

R5T ................. Thermistor (heat exchanger middle)

R6T ................. Thermistor (liquid)

R7T ................. Thermistor (fin) (only for W1 models)

R10T ............... Thermistor (fin) (only for V3 models)

RC ................... Signal receiver circuit (only for V3 models)

S1NPH ............ Pressure sensor

S1PH............... High pressure switch

TC ................... Signal transmission circuit (only for V3 models)

V1R ................. Power module

V2R ................. Power module (only for W1 models)

V2R,V3R ......... Diode module (only for V3 models)

V3R ................. Diode module (only for W1 models)

V1T .................. IGBT (only for V3 models)

X1M ................. Power supply terminal strip

Y1E.................. Electronic expansion valve

Y1S.................. Solenoid valve (4-way valve)

Y3S.................. Solenoid valve (only for W1 models)

Z1C~Z3C ......... Noise filter (ferrite core) (only for V3 models)

Z1C~Z9C ......... Noise filter (ferrite core) (only for W1 models)

Z1F~Z4F.......... Noise filter

OPTIONAL CONNECTOR

X1Y.................. Connector

X6A,X77A ........ Connector (only for W1 models)

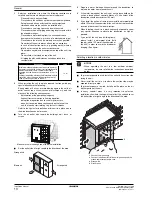

NOTES

1.

THIS WIRING DIAGRAM ONLY APPLIES TO THE COMPRESOR

MODULE SWITCH BOX

2.

L

: LIVE

N:

: NEUTRAL

: FIELD WIRING

3.

: TERMINAL STRIP

: CONNECTOR

: CONNECTION

: PROTECTIVE EARTH (SCREW)

: CONNECTOR

: NOISELESS EARTH

: TERMINAL

4.

NOT APPLICABLE

5.

DO NOT OPERATE THE UNIT BY SHORT-CIRCUITING

PROTECTION DEVICE S1PH

6.

COLOURS:

BLK

: BLACK

ORG

: ORANGE

BLU

: BLUE

RED

: RED

BRN

: BROWN

WHT

: WHITE

GRN

: GREEN

YLW

: YELLOW

7.

CONFIRM THE METHOD OF SETTING THE SELECTOR

SWITCHES (DS1) BY SERVICE MANUAL.

FACTORY SETTING OF ALL SWITCHES: "OFF".

8.

: OPTION

: WIRING DEPENDENT ON MODEL

POWER SUPPLY UNIT

POWER SUPPLY UNIT

TO HYDROMODULE

SWITCH BOX

TO HYDROMODULE SWITCH BOX

COMPRESSOR

MODULE SWITCH BOX

COMPRESSOR MODULE SWITCH BOX

COMPRESSOR

TERMINAL POSITION

COMPRESSOR TERMINAL POSITION

REACTOR BOX

REACTOR BOX

WIRE ENTRANCE

WIRE ENTRANCE