6

OVERCURRENT PROTECTION

The following overcurrent protection devices are approved for use.

•

Time delay fuses

•

HACR type circuit breakers

These devices have sufficient time delay to permit the motor-com-

pressor to start and accelerate its load.

Refer to the unit serial plate for the maximum overcurrent pro-

tection permitted.

Run all line voltage wiring a conduit from the service disconnect

box to the unit. Refer to the NEC (USA) or CEC (Canada) codes for

the correct size conduit based on the wire size. The conduit en-

ters the control box through the hole provided in the bottom.

NOTE:

The control box hole is sized for 3/4” conduit. If permitted

by code, a flexible conduit is preferred to minimize vibration trans-

mission from the unit to the building.

Connect the line voltage wires to the L1, L2, and L3 terminals of

the definite purpose contactor (located in the unit control box).

Refer to the wiring diagram attached to the unit when making

these connections.

THREE PHASE COMPRESSOR ROTATION

Use care when handling scroll compressors. Dome temperatures

could be hot.

CAUTION

Three phase scrolls are power phase dependent and can compress

in more than one direction.

Verify proper rotation for three phase compressors by ensuring

the suction pressure drops and discharge pressure rises when the

compressor is energized.

NOTE:

When operated in reverse, a three

phase scroll compressors is noisier and its current draw substan-

tially reduced compared to marked values.

To correct, disconnect power and switch any two leads at the unit

contactor and re-observe.

HIGH VOLTAGE CONNECTIONS

Route power supply and ground wires through the high voltage

port and terminate in accordance with the wiring diagram pro-

vided inside the control panel cover.

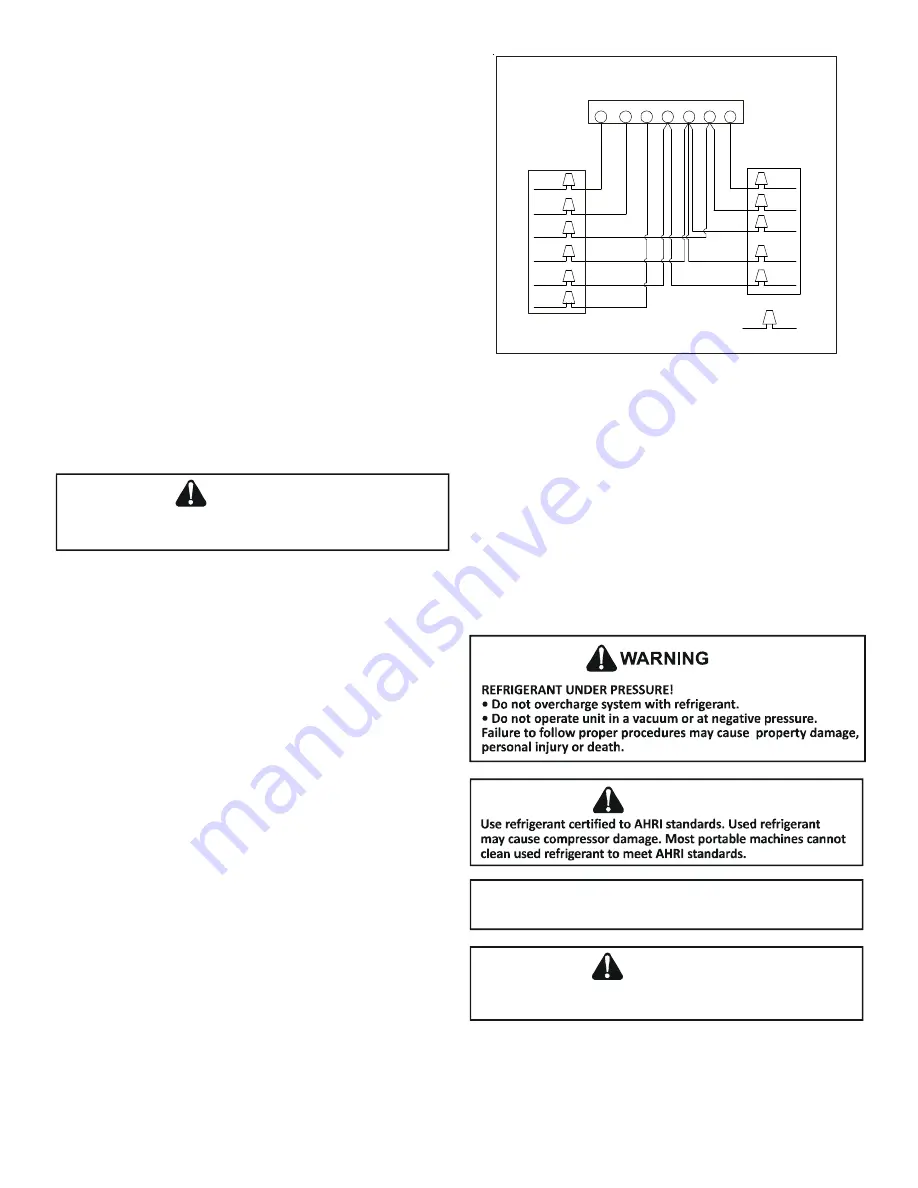

LOW VOLTAGE CONNECTIONS

Condensing unit control wiring requires a five-conductor low volt-

age circuit from the room thermostat (without options). The wires

should be no smaller than 18 AWG and the field connection for

this circuit must be made in the unit control box using solderless

connectors (i.e. wire nuts). See the following diagram for a typical

low voltage hook-up.

TWO STAGE LOW VOLTAGE HOOK-UP

THERMOSTAT

O

W2

C

R

RED

BROWN

WHITE

BLUE

BLUE

WHITE

CONDENSING

UNIT

AIR

HANDLER

YELLOW

PURPLE

RED

Y1

G

GREEN

Y2

WIRE NUT

ORANGE

SYSTEM START UP

Never operate the compressor with the suction valve

closed to

test the compressor’s pumping efficiency. In some

cases, this can

result in serious compressor damage and loss of warranty cover-

age.

For the 7-1/2 ton unit starting charge should be 18 lbs. of R-410A and

20 lbs. for the 10 ton unit. The length of line set, indoor unit air-

flow, condensing unit location and number of tubing fittings will

have an impact on final unit charge amount. Turn the electrical

power on, and let the system run. Wait for the refrigerant pres-

sures to stabilize.

CHARGE VERIFICATION

CAUTION

NOTICE

Violation of EPA regulations may result in fines or other penalties.

Operating the compressor with the suction valve closed will void

the warranty and cause serious compressor damage.

CAUTION