PRODUCT DESIGN

20

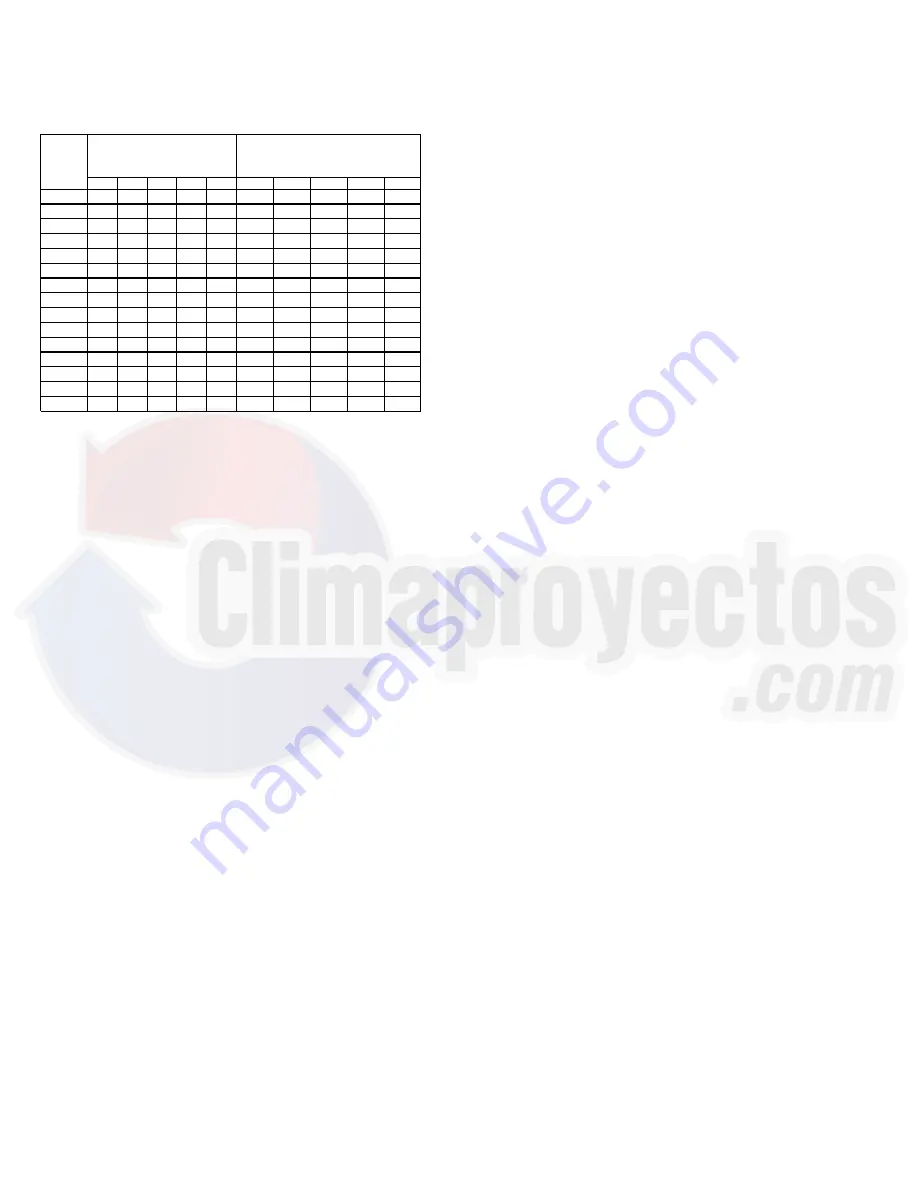

Sizing Between Single or Second Stage Regulator and Appliance*

Maximum Propane Capacities Listed are Based on 1/2" W.C. Pressure Drop at

11" W.C. Setting. Capacities in 1,000 BTU/HR

3/8"

1/2"

5/8"

3/4"

7/8"

1/2"

3/4"

1"

1-1/4"

1-1/2"

10

49

110

206

348

539

291

608

1,146

2,353

3,525

20

34

76

141

239

368

200

418

788

1,617

2,423

30

27

61

114

192

296

161

336

632

1,299

1,946

40

23

52

97

164

253

137

284

541

1,111

1,665

50

20

46

86

146

224

122

255

480

985

1,476

60

19

42

78

132

203

110

231

436

892

1,337

80

16

36

67

113

174

94

198

372

764

1,144

100

14

32

59

100

154

84

175

330

677

1,014

125

12

28

52

89

137

74

155

292

600

899

150

11

26

48

80

124

67

141

265

544

815

200

10

22

41

69

106

58

120

227

465

697

250

9

19

36

61

94

51

107

201

412

618

300

8

18

33

55

85

46

97

182

374

560

350

7

16

30

51

78

43

89

167

344

515

400

7

15

28

47

73

40

83

156

320

479

*DATA IN ACCORDANCE WITH NFPA PAMPHLET NO. 54

NOMINAL PIPE SIZE,

SCHEDULE 40

TUBING SIZE, O.D., TYPE L

PIPE OR

TUBING

LENGTH,

FEET

COOLING

The refrigerant used in the system is R-410A. It is a clear,

colorless, non-toxic and non-irritating liquid. R-410A is a

50:50 blend of R-32 and R-125. The boiling point at atmo-

spheric pressure is -62.9°F.

A few of the important principles that make the refrigeration

cycle possible are: heat always flows from a warmer to a

cooler body. Under lower pressure, a refrigerant will absorb

heat and vaporize at a low temperature. The vapors may be

drawn off and condensed at a higher pressure and tempera-

ture to be used again.

The indoor evaporator coil functions to cool and dehumidify

the air conditioned spaces through the evaporative process

taking place within the coil tubes.

NOTE:

The pressures and temperatures shown in the refrig-

erant cycle illustrations on the following pages are for dem-

onstration purposes only. Actual temperatures and pres-

sures are to be obtained from the "Expanded Performance

Chart".

Liquid refrigerant at condensing pressure and temperatures,

(270 PSIG and 122°F), leaves the outdoor condensing coil

through the drier and is metered into the indoor coil through

the metering device. As the cool, low pressure, saturated

refrigerant enters the tubes of the indoor coil, a portion of the

liquid immediately vaporizes. It continues to soak up heat and

vaporizes as it proceeds through the coil, cooling the indoor

coil down to about 48°F.

Heat is continually being transferred to the cool fins and tubes

of the indoor evaporator coil by the warm system air. This

warming process causes the refrigerant to boil. The heat

removed from the air is carried off by the vapor.

As the vapor passes through the last tubes of the coil, it

becomes superheated. That is, it absorbs more heat than is

necessary to vaporize it. This is assurance that only dry gas

will reach the compressor. Liquid reaching the compressor

can weaken or break compressor valves.

The compressor increases the pressure of the gas, thus

adding more heat, and discharges hot, high pressure super-

heated gas into the outdoor condenser coil.

In the condenser coil, the hot refrigerant gas, being warmer

than the outdoor air, first loses its superheat by heat trans-

ferred from the gas through the tubes and fins of the coil. The

refrigerant now becomes saturated, part liquid, part vapor and

then continues to give up heat until it condenses to a liquid

alone. Once the vapor is fully liquefied, it continues to give up

heat which subcools the liquid, and it is ready to repeat the

cycle.

HEATING

The heating cycle is accomplished by using a unique tubular

design heat exchanger which provides efficient gas heating

on either natural gas or propane gas fuels. The heat exchang-

ers compact tubular construction provides excellent heat

transfer for maximum operating efficiency.

Inshot type gas burners with integral cross lighters are used

eliminating the need for adjustable air shutters. The same

burner is designed for use on either natural or propane gas

fuels.

The induced draft blower draws fuel and combustion air into

the burners and heat exchanger for proper combustion. A

pressure switch is used in conjunction with the I. D. blower

to detect a blocked flue condition.

Blower operation is controlled by the ignition control module.

The module allows for field adjustment of the blower delay at

the end of the heating cycle. The range of adjustment is for

90, 120, 150 or 180 seconds. The factory delay setting is 30

seconds delay on 150 seconds delay off.

Direct Spark Ignition (DSI) Systems

DPGM units are equipped with a direct spark ignition system.

Ignition is provided by 22,000 volt electronic spark. A flame

sensor then monitors for the presence of flame and closes the

gas valve if flame is lost.