SERVICING

71

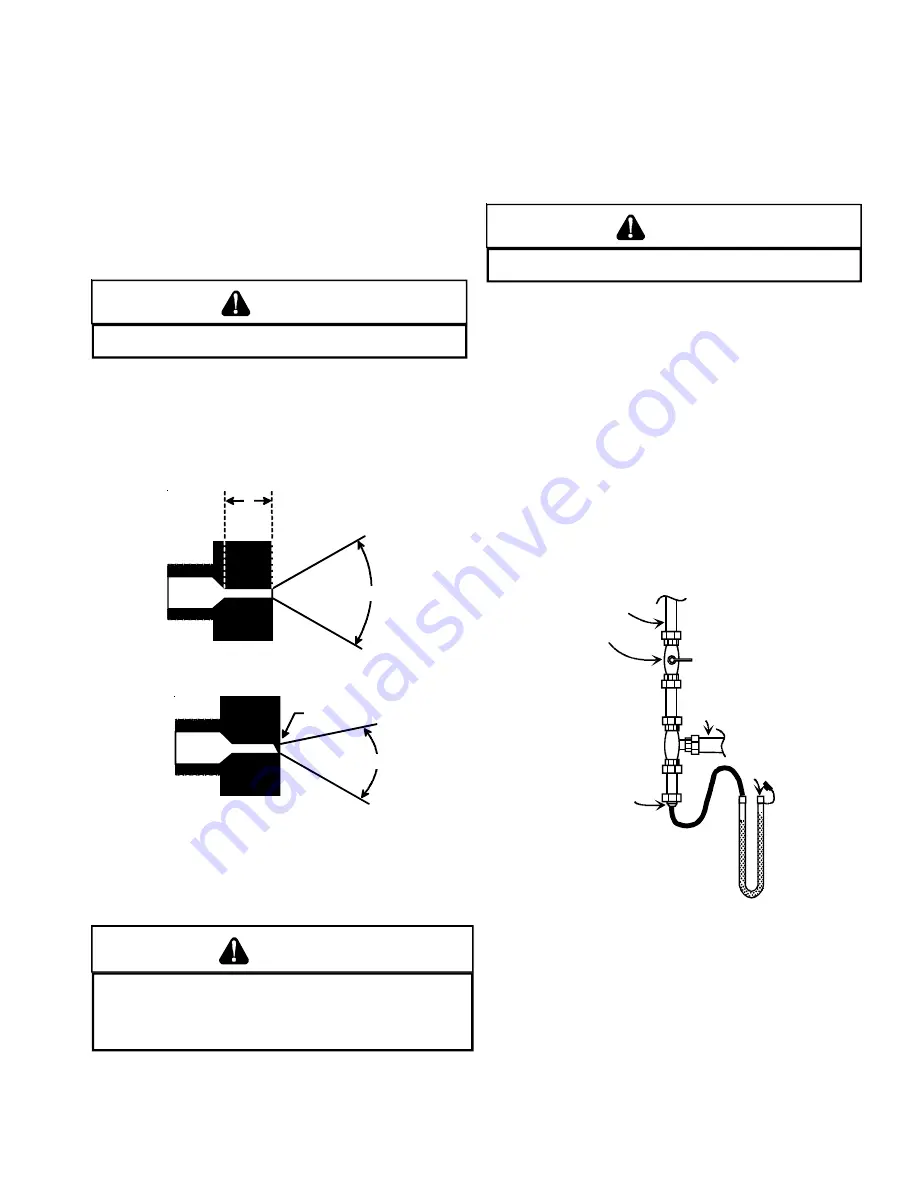

The only time resizing is required is when a reduction in

firing rate is required for an increase in altitude.

Orifices should be treated with care in order to prevent dam-

age. They should be removed and installed with a box-end

wrench in order to prevent distortion. In no instance should

an orifice be peened over and redrilled. This will change the

angle or deflection of the vacuum effect or entraining of pri-

mary air, which will make it difficult to adjust the flame prop-

erly. This same problem can occur if an orifice spud of a

different length is substituted.

WARNING

D

ISCONNECT

ALL

G

AS AND

E

LECTRICAL

P

OWER

S

UPPLY.

1. Check orifice visually for distortion and/or burrs.

2. Check orifice size with orifice sizing drills.

3. If resizing is required, a new orifice of the same physical

size and angle with proper drill size opening should be

installed.

A

GAS

STREAM B

The length of Dimension "A" determines the angle of Gas

Stream "B".

DENT OR

BURR

GAS

STREAM B

A dent or burr will cause a severe deflection of the gas

stream.

S-307 CHECKING GAS PRESSURE

Gas Supply Pressure Measurement

T

O PREVENT UNRELIABLE OPERATION OR EQUIPMENT DAMAGE, THE

INLET GAS SUPPLY PRESSURE MUST BE AS SPECIFIED ON THE UNIT

RATING PLATE WITH ALL OTHER HOUSEHOLD GAS FIRED APPLIANCES

OPERATING.

CAUTION

Gas inlet and manifold pressures should be checked and

adjusted in accordance to the type of fuel being consumed.

The line pressure supplied to the gas valve must be within

the range specified below. The supply pressure can be mea-

sured at the gas valve inlet pressure tap or at a hose fitting

installed in the gas piping drip leg. The supply pressure must

be measured with the burners operating. To measure the

gas supply pressure, use the following procedure.

WARNING

D

ISCONNECT ELECTRICAL POWER AND SHUT OFF GAS SUPPLY.

1. After turning off gas to furnace at the manual gas shutoff

valve external to the furnace, remove burner compart-

ment door to gain access to the gas valve.

2. Connect a calibrated water manometer (or appropriate

gas pressure gauge) at either the gas valve inlet pres-

sure tap or the gas piping drip leg as shown in the fol-

lowing figures. Refer to

Measuring Gas Pressure: Single

Stage Valves

figure for single stage valve inlet pressure

tap connections. Refer to

Measuring Gas Pressure: Two-

Stage Valves

figure for two-stage gas valve inlet pres-

sure tap connections.

NOTE:

At either location, a hose fitting must be installed

prior to making the hose connection.

NOTE:

Use apapter kit #0151K00000S to measure gas pres-

sure on White-Rodgers 36G22 and 36G54 gas valves.

GAS LINE

GAS SHUTOFF VALVE

GAS LINE

TO FURNACE

DRIP LEG CAP

WITH FITTING

MANOMETER HOSE

MANOMETER

OPEN TO

ATMOSPHERE

Measuring Inlet Gas Pressure

(Alternate Method)

3. Turn ON the gas and electrical power supply and oper-

ate the furnace and all other gas consuming appliances

on the same gas supply line.

4. Measure furnace gas supply pressure with burners fir-

ing. Supply pressure must be within the range specified

in the following table.