PRODUCT DESIGN

30

Humidifier Wiring

There are several options for connecting humidifier wiring to

the current communicating furnace control board

(PCBKF103, PCBK104, and PCBKF105)

Single HUM terminal

The single HUM terminal is energized

with 115 volts whenever the draft inducer is running. This

function is present regardless of thermostat type. This ter-

minal may be used to power a humidifier transformer. A

field supplied humidistat must be provided with this option.

HUM IN – HUM OUT Terminals

Present on communicating

furnace models built with a (PCBKF103,PCBK104, and

PCBKF105) board. These terminals may be used when a

CTK02** or CTK03AB communicating thermostat is used.

These thermostats are capable of initiating a call for

humidity.The HUM IN – HUM OUT terminals are not ener-

gized by factory wiring and must be field wired.Typical wir-

ing would be to supply the HUM IN contact with 115 volts

from the furnace L1 terminal and connect a line voltage hu-

midifier / transformer between HUM OUT and the control

board neutral.

Options for control:

With the CTK02 thermostat. From the Main Menu > Clock

& Display > Hum Display > (On). Enter the Advanced menu

by pressing left and right arrows for three seconds > Com

Devices > Furnace > Setup > Humidity > (On or Indepen-

dent) If “On” is selected, the HUM IN – HUM OUT contacts

will close during a call for heat if the room humidty is below

the humidity set point selected on the CTK02**. The control

board also runs the furnace blower on constant fan speed

to support the call for humidification. If “IND” is selected,

the HUM IN – HUM OUT contacts will close with or without

a call for heat if the room humidity is below the humidity

setpoint selected on the CTK02**. The control board also

runs the furnace blower on constant fan speed to support

the call for humidification.

With the CTK03AB & CTK04AA thermostat. From the Main

Menu > Installer Options (enter 4 digit passcode from the

Dealer Information Menu) > View / Edit Current Setup >

Humidification > Humidifier Type (Steam or Bypass / fan

powered) > Modes Allowing Humidification (Heat, Off) > Hu-

midification Control > (Humidify only when fan is on, Hu-

midify on demand – thermostat controls fan, Humidify on

demand – equipment controls fan)

24 VOLT THERMOSTAT WIRING

NOTE:

Low voltage connections can be made through ei-

ther the right or left side panel. Wire routing must not inter-

fere with circulator blower operation, filter removal, or rou-

tine maintenance.

A 40 V.A. transformer and an integrated electronic control

are built into the furnace to allow use with most cooling

equipment. Consult the wiring diagram, located in the Tech-

nical Manual or on the blower door for further details of 115

Volt and 24 Volt wiring.

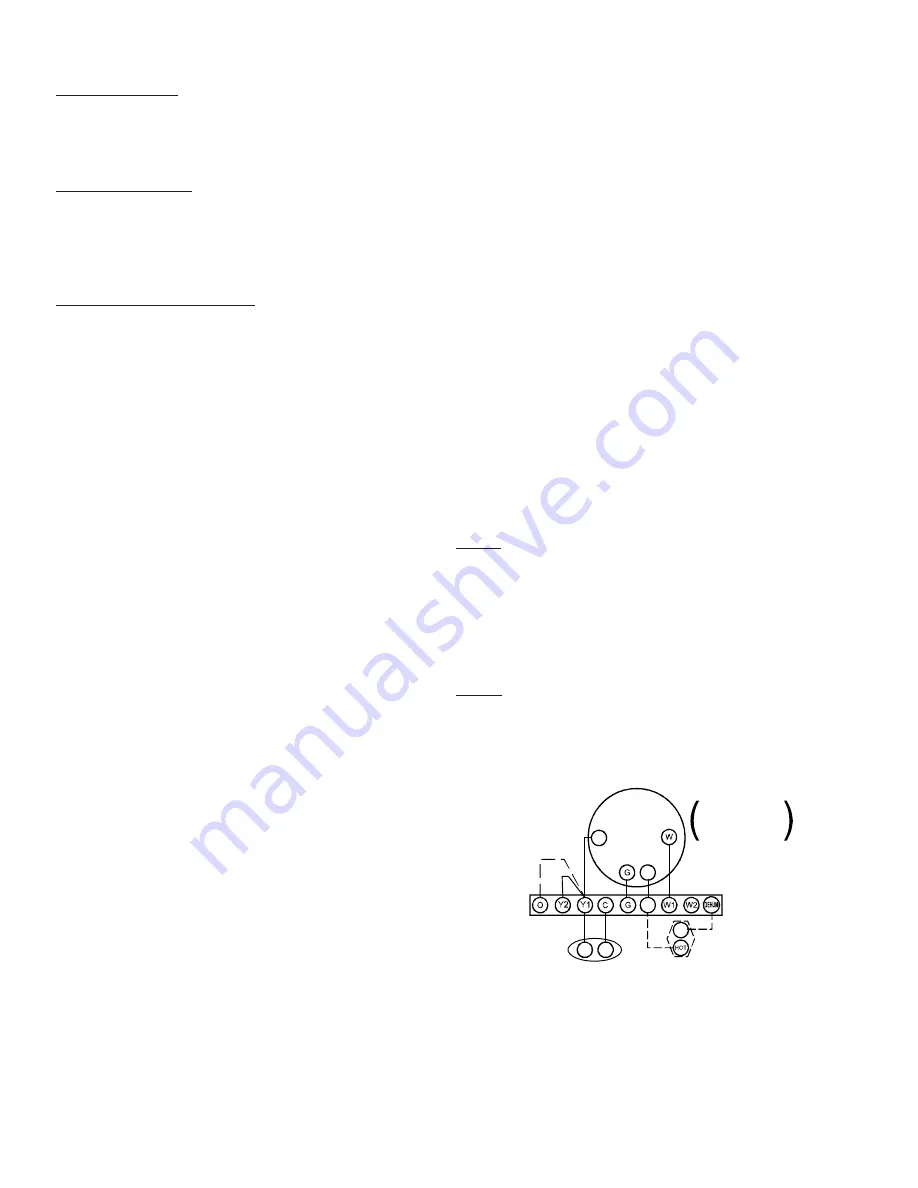

Low voltage connections can be made through either the

right or left side panel. Thermostat wiring entrance holes

are located in the blower compartment. The following figure

shows connections for a “heat only” system and “heat/cool

system”.

Thermostat Wiring - Two-Stage Variable Speed

ComfortNet™ Furnaces (WR 50C51)

As a two-stage non-communicating furnace, the furnace

integrated control module provides terminals for both “W1”

and “W2”, and “Y1” and “Y2” thermostat connections. This

allows the furnace to support the following system applica-

tions: ‘Two-Stage Heating Only’, ‘Two-Stage Heating with

Single Stage Cooling’, and ‘Two-Stage Heating with Two-

Stage Cooling’. Refer to the following figures for proper

connections to the integrated control module.

Low voltage connections can be made through either the

right or left side panel. Thermostat wiring entrance holes

are located in the blower compartment. The following figure

shows connections for a “heat/cool system”.

This furnace is equipped with a 40 VA transformer to facili-

tate use with most cooling equipment. Consult the wiring

diagram, located on the blower compartment door, for fur-

ther details of 115 Volt and 24 Volt wiring.

NOTE:

For single stage cooling applications, a jumper may

be required between Y1 and Y2 at the furnace control in

order to achieve the desired single stage cooling airflow.

Consult the blower performance tables to determine if the

required single stage cooling airflow can be delivered at low

stage (Y1 input) or high stage (Y2 input). Additionally, use

of ramping profile features require a jumper between Y1 and

O when used with a straight cooling unit.

NOTE:

Thermostat “R” required if outdoor unit is equipped

with a Comfort Alert™ module or if the out door unit is a

part of the ComfortNet family of equipment AND is wired as

a legacy system.

Y

R

R

Y

C

NEU

Furnace Integrated

Control Module

Remote

Condensing Unit

(Single-Stage Cooling)

Dehumidistat

[Optional]

To apply a single-stage Heating Thermostat,

the thermostat selector switch on the

Integrated Control Module

be set on

single-stage.

must

NOTE:

Single Stage Heating with Single Stage Cooling

Thermostat

Single Stage Heating with

Single Stage Cooling

Place Jumper Between Y1

and O For Proper

Dehumidification Operation

and Proper Ramping

Profile Operation