26

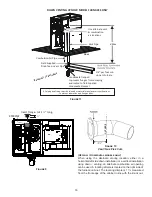

This furnace is equipped with a 40 VA transformer to

facilitate use with most cooling equipment. Consult the

wiring diagram, located on the blower compartment door,

for further details of 115 Volt and 24 Volt wiring.

R

Y

C

Furnace Integrated

Control Module

Remote Condensing Unit

(Single-Stage Cooling)

R

Room

Thermostat

Figure 30

Single-Stage Heating Thermostat Application

A single-stage thermostat with only one heating stage is

needed to control this furnace.

Fossil Fuel Applications

This furnace can be used in conjunction with a heat pump

in a fossil fuel application. A fossil fuel application refers to a

combined gas furnace and heat pump installation which uses

an outdoor temperature sensor to determine the most cost

efficient means of heating (heat pump or gas furnace).

Strictly follow the wiring guidelines in the fossil fuel kit

installation instructions. All furnace connections must be

made to the furnace two-stage integrated control module and

the “FURNACE” terminal strip on the fossil fuel control board.

GAS SUPPLY AND PIPING

WARNING

Possible property damage, personal injury or death may

occur if the correct conversion kits are not installed. The

appropriate kits must be applied to ensure safe and proper

furnace operation. All conversions must be performed by a

qualified installer or service agency.

WARNING

To avoid possible unsatisfactory by operation of equipment

damage due to underfiring or equipment, use the proper size

of natural/propane gas piping needed when running pipe from

the meter/tank to the furnace.

The furnace rating plate includes the approved furnace gas

input rating and gas types. The furnace must be equipped

to operate on the type of gas applied. This includes any

conversion kits required for alternate fuels and/or high

altitude.

Inlet gas supply pressures must be maintained within the

ranges specified in the following table. The supply pressure

must be constant and available with all other household

gas fired appliances operating. The minimum gas supply

pressure must be maintained to prevent unreliable ignition.

The maximum must not be exceeded to prevent unit

overfiring.

High Altitude Derate

When this furnace is installed at high altitude, the appropriate

High Altitude orifice kit must be applied. This is required due

to the natural reduction in the density of both the gas fuel

and combustion air as altitude increases. The kit will provide

the proper design certified input rate within the specified

altitude range.

High altitude kits are purchased according to the installation

altitude and usage of either natural or propane gas. Consult

the furnace Specification Sheet for appropriate kits.

Do not derate the furnace by adjusting the manifold

pressure to a lower pressure than specified on the furnace

rating plate. The combination of the lower air density and

a lower manifold pressure will prohibit the burner orifice

from drawing the proper amount of air into the burner. This

may cause incomplete combustion, flashback, and possible

yellow tipping.

In some areas the gas supplier may artificially derate the

gas in an effort to compensate for the effects of altitude.

If the gas is artificially derated, the appropriate orifice size

must be determined based upon the BTU/ft3 content of the

derated gas and the altitude. Refer to the National Fuel

Gas Code, NFPA 54/ANSI Z223.1 or CAN/CSA B149.1-15

in Canada, and information provided by the gas supplier to

determine the proper orifice size.

A different pressure switch may be required at high altitude

regardless of the BTU/ft3 content of the fuel used. Consult

the furnace Specification Sheet for pressure switch.

Propane Gas Conversion

This unit is configured for natural gas. To operate this furnace

on L.P. gas, an LPM-07 LP Conversion kit must be used.

The indicated kit must be used to insure safe and proper

furnace operation. All conversions must be performed by a

qualified installer, or service agency.

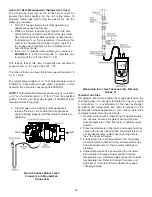

Gas Valve

This unit is equipped with a 24 volt gas valve controlled

during furnace operation by the integrated control module.

As shipped, the valve is configured for natural gas. The valve

is field convertible for use with propane gas by replacing

the regulator spring with a propane gas spring from an

appropriate manufacturer’s propane gas conversion kit.

Taps for measuring the gas supply pressure and manifold

pressure are provided on the valve.