13 Disposal

Installer reference guide

77

EPGA11~ EA9W

Daikin Altherma – Low temperature split

4P556075-1 – 2019.02

INFORMATION

In case of an E7‑62 error, brine pump operation stops due

to not enough flow in the brine circuit. If 10‑day brine pump

operation is running, it will stop running and will only

resume once the error is reset. It is only possible to reset

the error with the domestic hot water home screen or the

leaving water temperature home screen turned ON. To

reset the error, press

and confirm by pressing

.

INFORMATION

If an U8‑04 error occurs, the error can be reset after a

successful update of the software. If the software is not

successfully updated then you must make sure that your

USB device has the FAT32 format.

INFORMATION

How an error code can be reset will be displayed on the

user interface connected on the indoor unit.

13

Disposal

NOTICE

Do NOT try to dismantle the system yourself: dismantling

of the system, treatment of the refrigerant, oil and other

parts MUST comply with applicable legislation. Units

MUST be treated at a specialised treatment facility for

reuse, recycling and recovery.

13.1

Overview: Disposal

Typical workflow

Disposing of the system typically consists of the following stages:

1

Pumping down the system.

2

Performing vacuum drying.

3

Bringing the system to a specialized treatment facility.

INFORMATION

For more details, see the service manual.

13.2

To pump down

DANGER: RISK OF EXPLOSION

Pump down – Refrigerant leakage.

If you want to pump

down the system, and there is a leak in the refrigerant

circuit:

▪ Do NOT use the unit's automatic pump down function,

with which you can collect all refrigerant from the

system into the outdoor unit.

Possible consequence:

Self-combustion and explosion of the compressor

because of air going into the operating compressor.

▪ Use a separate recovery system so that the unit's

compressor does NOT have to operate.

NOTICE

During pump down operation, stop the compressor before

removing the refrigerant piping. If the compressor is still

running and the stop valve is open during pump down, air

will be sucked into the system. Compressor breakdown or

damage to the system can result due to abnormal pressure

in the refrigerant cycle.

Pump down operation will extract all refrigerant from the system into

the outdoor unit.

1

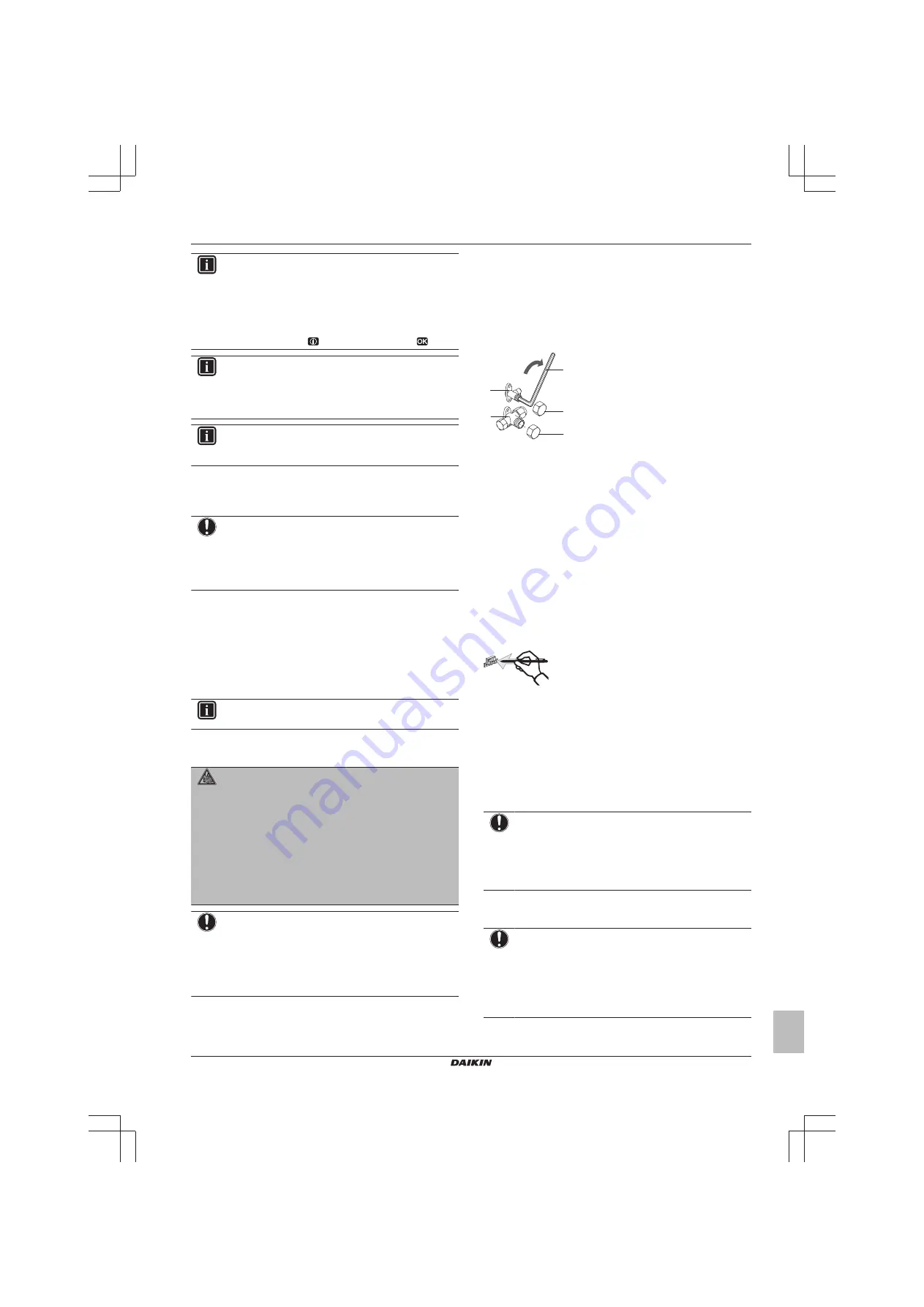

Remove the valve lid from the liquid stop valve and the gas stop

valve.

2

Install a manifold on the gas stop valve.

3

After 5 to 10 minutes (after only 1 or 2 minutes in case of very

low ambient temperatures (<−10°C)), close the liquid stop valve

with a hexagonal wrench.

4

Check on the manifold if the vacuum is reached.

5

After 2-3 minutes, close the gas stop valve and stop forced

cooling operation.

a

c

b

d

d

e

a

Liquid stop valve

b

Closing direction

c

Hexagonal wrench

d

Valve lid

e

Gas stop valve

13.3

To activate/deactivate the vacuum

mode field setting

To perform vacuum drying of the outdoor unit’s internal refrigerant

piping it is necessary to activate the vacuum mode. This will open

required valves in the refrigerant circuit so the vacuuming process

can be done properly.

To activate vacuum mode:

Activating the vacuum mode is done by operating the BS1 push

button on the PCB (A1P). Operate the switches and push buttons

with an insulated stick (such as a closed ball-point pen) to avoid

touching of live parts.

When the unit is powered on and not running, push the BS1 push

button 3 times within a time frame of 10 seconds to activate vacuum

mode.

To deactivate vacuum mode:

After vacuuming the unit, please deactivate the vacuum mode by

pushing the BS1 push button 3 times within a time frame of 10

seconds.

Make sure to reattach the electronic component box cover and to

install the front cover after the job is finished.

NOTICE

Make sure that all outside panels, except for the service

cover on the electrical component box, are closed while

working.

Close the lid of the electrical component box firmly before

turning on the power.

13.4

To perform vacuum drying

NOTICE

▪ Connect the vacuum pump to

both

the service port of

the gas stop valve and the service port of the liquid

stop valve to increase efficiency.

▪ Make sure that the gas stop valve and liquid stop valve

are firmly closed before performing the leak test or

vacuum drying.

1

Vacuum the system until the pressure on the manifold indicates

−0.1 MPa (−1 bar).