DAIHAN-Sci.com or

ALL

for

LAB.com

Shopping Mall

DAIHAN Scientific, Forced Convection type Smart Oven 38/80

4. Products Management

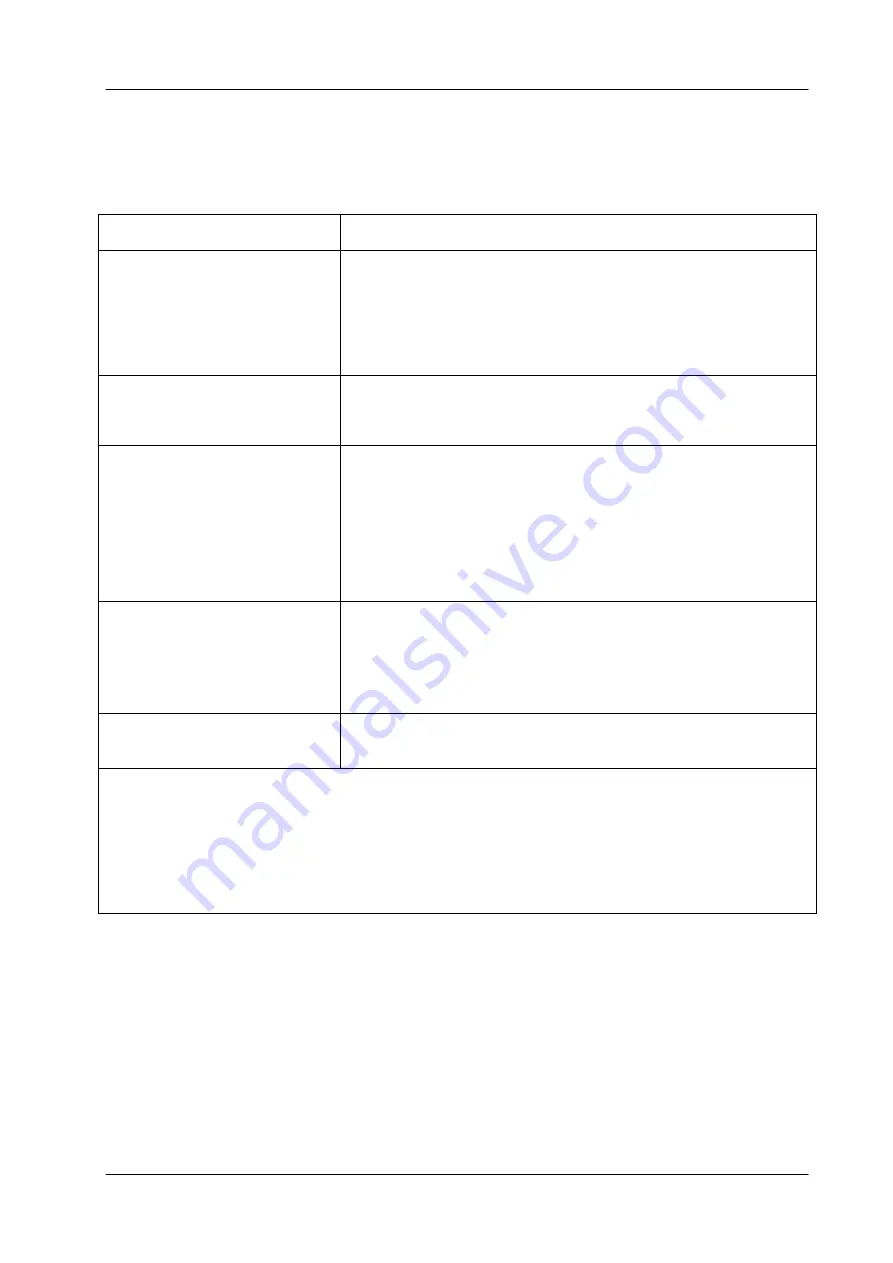

4.2 Troubleshooting and solution

Situation

Confirmations and Solutions

If power does not turn ON.

Make sure that Power Cord is plugged well.

Check that there are no problems in the power supplied.

Make sure that the circuit breaker is in the ON position.

Check the short circuit status of the fuse.

Power Failure

Check the power cord is plugged into wall socket.

Check the supplied voltage is proper and regulated.

Heating, but temperature is

fluctuated

Check the temperature that is currently set.

Make sure that the power switch is in the ON position.

Check that SAFETY Knob is not placed in the “0” position, and

if SAFETY Knob is in the “0” position, sets up 30

~40

℃

℃

higher than the service temperature.

Heating, but unit not reaching

temperature

Check the Set Temperature is higher than ambient

temperature (recommended min set temp: 10

℃

higher than

ambient temp).

Problem in the sensor or main controller.

Fuse is blown OR circuit

breaker is flickered.

Check power source of wall socket and see what other loads

are on wall circuit.

※

If you have any problem other than the above, please call technical service of manufacturer

or an official agent.