3. DIRECTIONS FOR INSTALLATION AND USE

4

DIRECTIONS

The openings must not

be obstructed by carpet-

ing when the washing

machine is installed on a

carpeted floor.

⏿

⏿

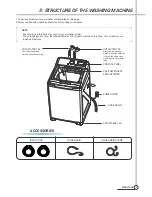

How To Install On An Inclined Place

ᵄ

The place where it would be exposed to

direct sunlight.

ᵄ

The place nearby a heater or heat

appliance.

ᵄ

The place where it would be supposed

to be frozen in winter.

ᵄ

The kitchen with coal gas and a damp

place like a bathroom.

NOTES

10Cm

Install the washer on a horizontal

solid floor. If the washer is installed

on an unsuitable floor, it could make

considerable noise and vibration.

INSTALLING PLACE

Never install in these places

2

Check the Horizon

Status

Check the position of tub above

the center of the washer.

1

Horizon

Setting

After controlling the height

by turning the adjustable

leg, let the washer put

down to the ground.

Keep the machine body

more than

25cm(9.85inches) apart

from the wall surface. It will

make easy cleaning the

drain filter which is equipped

at the back side of it. And if

it comes into contract

vibration may occur.

25cm(9.85inches)

⏿

⏿

How to Connect the Inlet Hose

Be careful not to mistake in supplying between the hot(maximum : 50

˚

C) and cold water.

In using only one water tap or in case of attached one water inlet valve, connect the inlet hose to the cold water inlet valve.

Do not over tighten : this could cause damage to couplings.

FOR SCREW-SHAPED TAP

3

Insert the inlet hose adapter

into the water inlet of a washer

and turn it to be fixed.

• Check the packing in the inlet

1

Connect the inlet

hose to the water tap

by screwing the

connector D tightly.

2

Connect the

connector-inlet

supplied if necessary.

Connector D

Rubber

Packing

Inlet Hose

Connector C

Connector

Inlet

Rubber

Packing

Inlet Hose

Connector C

Connector D